Long-acting mildew-proof polyacrylate modified casein composite emulsion and preparation method thereof

The technology of polyacrylate and composite emulsion is applied in the field of anti-mildew materials, which can solve the problem of easy mildew of casein emulsion, and achieve the effects of economical and feasible raw materials, simple process method and cheap raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

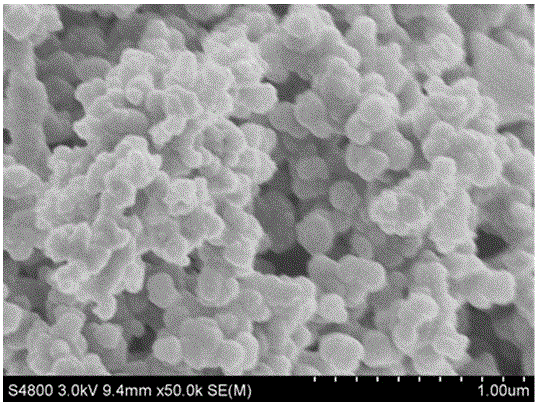

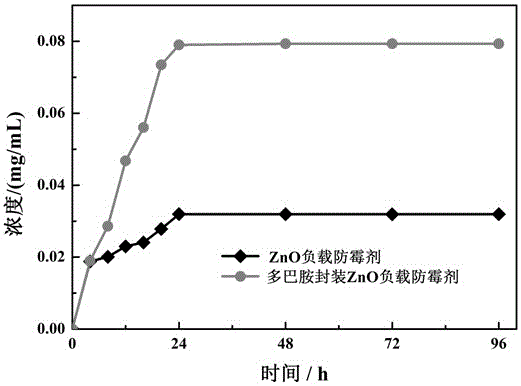

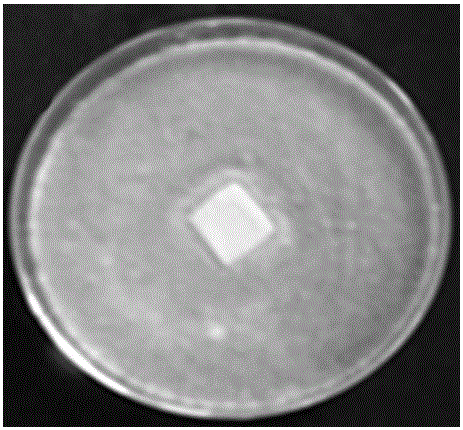

[0044] Step 1: Preparation of dopamine-coated modified drug-loaded hollow ZnO composite antifungal agent:

[0045] Weigh 0.01g of hollow ZnO microspheres and place them in a 10mL volumetric flask filled with 2-thiocyanomethylthiobenzothiazole solution with a mass volume concentration of 1.13g / mL, adjust the pH of the system to 8.5, and the solution temperature to 40°C , shake well, then age for 24 hours, centrifuge and dry the precipitate to obtain drug-loaded hollow ZnO;

[0046]Take 0.01g of drug-loaded hollow ZnO and place it in a volumetric flask filled with 10mL of dopamine solution with a mass volume concentration of 5.0mg / mL, adjust the pH of the system to 8, and place the volumetric flask in a water bath with a temperature of 37°C and a speed of 160r / min. Shake in a water-bath shaker for 6 hours, and finally, centrifuge and place the precipitate in an oven at 40°C for 10 hours, that is, dopamine-coated modified drug-loaded hollow ZnO composite antifungal agent;

[004...

Embodiment 2

[0058] Step 1: Preparation of dopamine-coated modified drug-loaded hollow ZnO composite antifungal agent:

[0059] Weigh 0.01g of hollow ZnO microspheres and place them in a 10mL volumetric flask filled with 2-thiocyanomethylthiobenzothiazole solution with a mass volume concentration of 2.06g / mL, adjust the pH of the system to 7, and the solution temperature to 50°C , shake well, then age for 24 hours, centrifuge and dry the precipitate to obtain drug-loaded hollow ZnO;

[0060] Take 0.01g of drug-loaded hollow ZnO and place it in a volumetric flask filled with 10mL of dopamine solution with a mass volume concentration of 3.0mg / mL, adjust the pH of the system to 8, and place the volumetric flask in a water bath with a temperature of 37°C and a speed of 160r / min. Shake in a water bath shaker for 6 hours, and finally, centrifuge and place the precipitate in an oven at 30°C for 11 hours, that is, dopamine-coated modified drug-loaded hollow ZnO composite antifungal agent;

[0061...

Embodiment 3

[0072] Step 1: Preparation of dopamine-coated modified drug-loaded hollow ZnO composite antifungal agent:

[0073] Weigh 0.01g of hollow ZnO microspheres and place them in a 10mL volumetric flask filled with 2-thiocyanomethylthiobenzothiazole solution with a mass volume concentration of 3g / mL, adjust the pH of the system to 6, and the solution temperature to 60°C. Shake well, then age for 24 hours, centrifuge and dry the precipitate to obtain drug-loaded hollow ZnO;

[0074] Take 0.01g of drug-loaded hollow ZnO and place it in a volumetric flask filled with 10mL of dopamine solution with a mass volume concentration of 1.0mg / mL, adjust the pH of the system to 8.5, and place the volumetric flask in a water bath with a temperature of 37°C and a speed of 160r / min. Shake in a water bath shaker for 6 hours, and finally, centrifuge and place the precipitate in an oven at 25°C for 12 hours, that is, dopamine-coated modified drug-loaded hollow ZnO composite antifungal agent;

[0075] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com