Solid state fermentation device, system and fermentation method of movable material distribution

A technology of solid-state fermentation and moving cloth, applied in the field of fermentation, can solve the problems of lack of standardized control of fermentation production, large area of fermentation equipment, high labor intensity of fermentation production, etc., to achieve easy control of equipment structure, high degree of automation, and equipment Maintain and standardize production of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

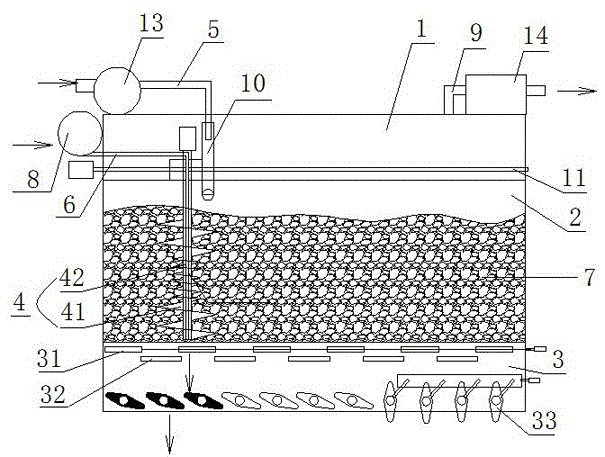

[0062] Example 1 Construction of the fermentation plant

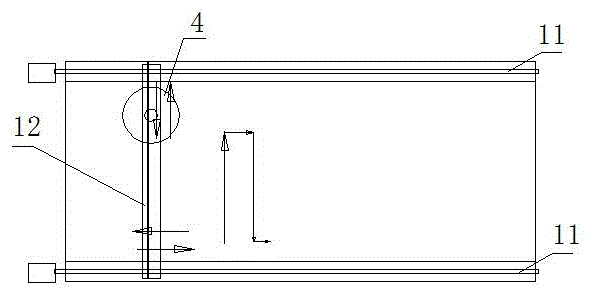

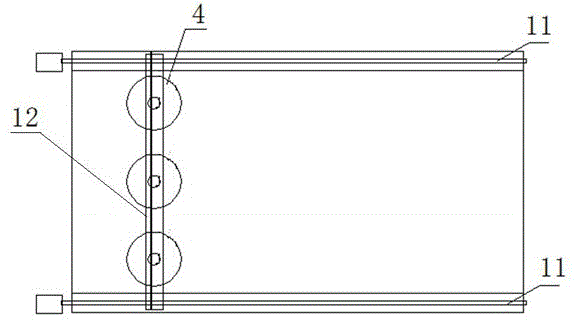

[0063] as attached figure 1 As shown, the present embodiment provides a solid-state fermentation device, including a working bin 1, a fermentation bin 2, and a quantitative discharge bin 3, and the working bin 1, the fermentation bin 2, and the quantitative output bin 3 are detachably connected to form a fermentation tank. Equipment: the working chamber 1, the fermentation chamber 2, and the quantitative discharge chamber 3 are independent chamber structures, and after the external connection of the three chambers, a fermentation space is formed that is externally sealed and internally communicated. When a certain warehouse structure fails, the entire warehouse structure can be removed for maintenance, replaced by a new alternative corresponding warehouse structure, and the subsequent fermentation work can be continued, so as not to cause production stagnation due to maintenance and affect The continuation of the fer...

Embodiment 2

[0082] Example 2 Construction of fermentation system

[0083] as attached figure 1 As shown, this embodiment provides a fermentation system, including a feeder 13, an air intake system 8 and an exhaust system, and also includes a turnover box (not shown in the figure) and the fermentation device described in Embodiment 1;

[0084] The feeder 13 is connected to the distributing device 10 of the fermenting device through the feeding pipe 5, the air intake system 8 is connected to the stirring device 4 of the fermenting device through the air inlet pipe 6, and the exhaust system is connected to the fermenting device. exhaust pipe 9;

[0085] The turnover box is a container-like structure with an openable top, and the top is opened to fit and connect with the bottom of the quantitative discharge bin 3 .

[0086] The exhaust pipe is arranged on the top of the working chamber, the exhaust system includes an exhaust fan 14, a heat pump system provided with an evaporator and a con...

Embodiment 3

[0090] Example 3 Fermentation application

[0091] Based on the fermentation device and fermentation system of the present invention, the present invention provides a new fermentation production process, which is a container-type layered fermentation method, comprising the following steps:

[0092] S1. Connect the working bin, the fermentation bin and the quantitative output bin, construct the fermentation device, and connect the feeder, the intake system and the exhaust system through the feeding pipe, the intake pipe, and the exhaust pipe, and prepare the turnover box to form the fermentation system;

[0093] S2. Adding materials according to the conventional fermentation requirements, and maintaining fermentation in a sealed and heat-preserving environment;

[0094] S3. After the number of days of fermentation is completed as required, the upper grid and the lower grid on the upper part of the quantitative discharge bin are overlapped, and the material falls evenly into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com