A kind of mineral standard sample for nano CT and its preparation method and application

A standard sample and mineral technology, applied in the preparation of test samples, material analysis using radiation, etc., can solve the problems of identifying minerals, the complexity of rock minerals, and the lack of methods for nano-CT rock mineral identification, etc., to improve efficiency, Avoid the effects of multiple CT calibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

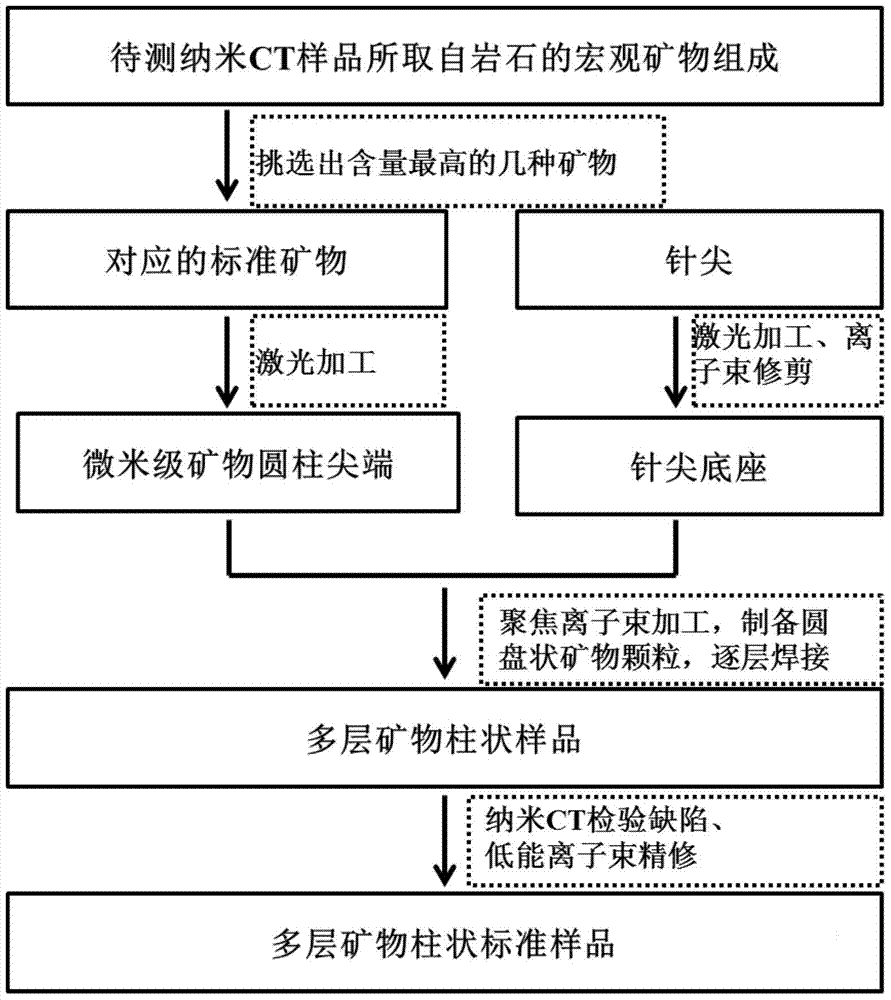

[0048] The present embodiment provides a mineral standard sample of nano-CT, which is prepared through the following steps (the specific process is as follows: figure 1 shown):

[0049] (1) Select standard mineral particles according to the mineral composition of the rock to be tested

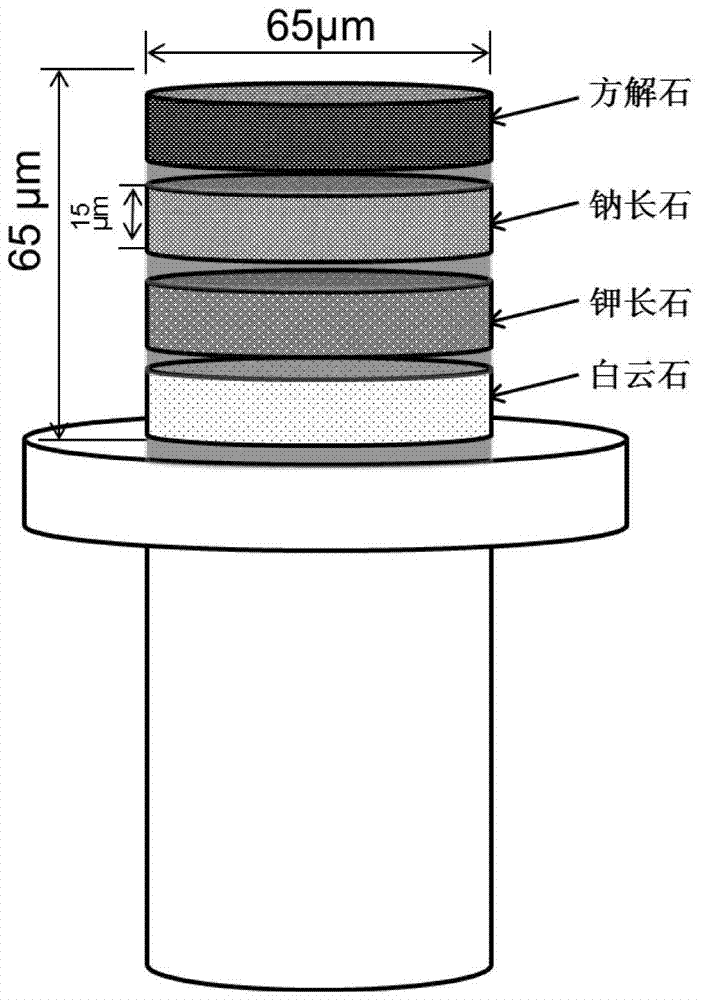

[0050] Firstly, the four minerals with the most content in the tight carbonate rock sample are calcite, albite, potassium feldspar and dolomite, and the corresponding standard mineral particles are selected;

[0051] (2) Make standard mineral particles into mineral sample discs

[0052] Firstly, the selected four standard mineral particles were mechanically cut, surface polished (metallographic polishing method), cleaned and dried to obtain a mineral sample piece with a diameter of 2 cm and a thickness of 2 cm, and the sample was glued to the A -532-DW Double Workstation Sample Preparation Systems laser micromachining system sample stage;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com