Treatment method and apparatus of dimethyl sulfoxide production tail gas

A dimethyl sulfoxide and treatment method technology, which is applied in the field of tail gas treatment of dimethyl sulfoxide production, can solve problems such as non-compliance with environmental protection emission standards, waste of resources, uneconomical, etc., to save resources and costs, avoid waste, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

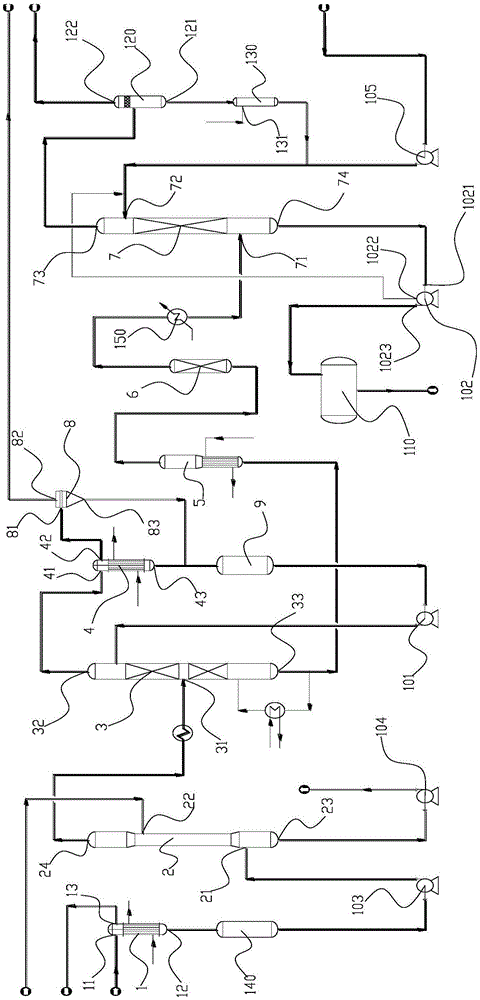

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] The processing method of DMSO production tail gas of the present invention may further comprise the steps:

[0031] A, the exhaust gas is cooled, methyl mercaptan, dimethyl sulfide and methanol in the exhaust gas are condensed into mixed liquid A, and most of the hydrogen sulfide remains in gaseous state, which is separated from mixed liquid A;

[0032] B. Mix the mixed solution A with water, separate the methanol easily soluble in water, and obtain the mixed solution B;

[0033] C, stripping and separating the hydrogen sulfide dissolved in the mixed solution B to obtain the mixed solution C;

[0034] D. Heat the mixed liquid C into a gaseous state, use a desulfurizer to absorb hydrogen sulfide in the mixed gas, and perform fine desulfurization;

[0035] E. Pass the gas obtained in step D into sodium hydroxide or potassium hydroxide solution to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com