Method for desulfurizing and recovering NOx with alkali liquor

A lye and alkaline technology, applied in the preparation, separation method, chemical instrument and method of alkali metal sulfite, can solve the problems of high consumption value, low system investment, low resource and energy consumption, etc., and achieve operating costs. Low, wide adaptability, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

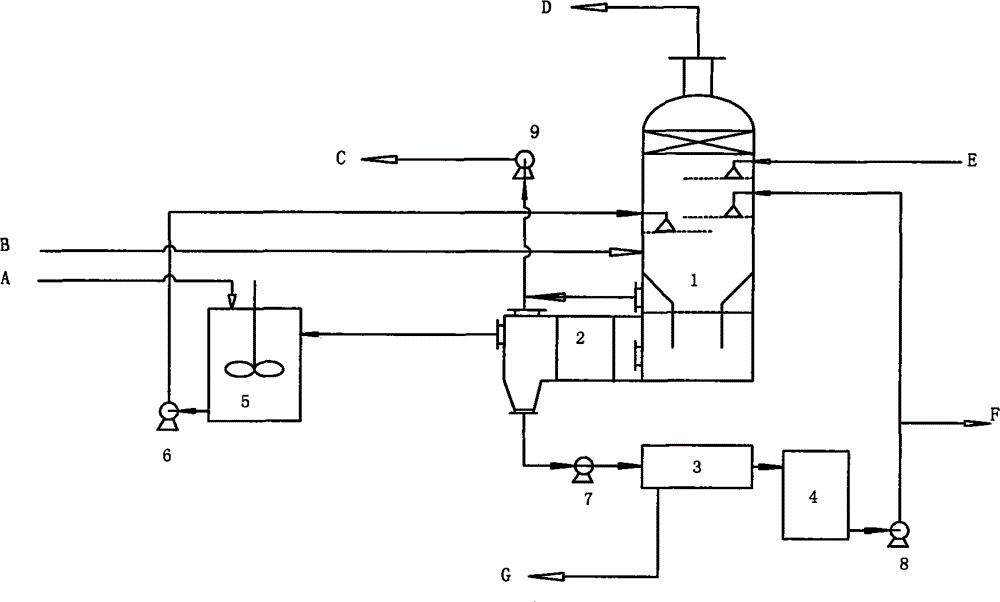

[0031] figure 1 Medium desulfurization and denitrification absorption tower 1, analysis device 2, filter 3, filtrate tank 4, feeding tank 5, feed liquid pump 6, slurry pump 7, filtrate pump 8, vacuum pump 9; alkali material A, flue gas B, analysis gas C , Purify flue gas D, wash process water E, recover sulfur F, waste residue G.

[0032] The flue gas B at a temperature of 150°C enters the middle part of the desulfurization and denitrification absorption tower 1, and is in countercurrent contact with the circulating slurry, filtrate and washing process water sprayed from the upper part. After spraying and washing, the dust, sulfur dioxide and nitrogen in the flue gas The pollutants are removed, and the purified flue gas D leaves the absorption system at a temperature of about 50°C and sends it to the chimney. The slurry in the tower flows through the analysis device 2 outside the tower, most of the fluid is sent to the feeding tank 5 and the input alkali material A preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com