Preparation method for adsorption catalyst for removing indoor formaldehyde

A formaldehyde adsorption and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of small gas molecule adsorption, non-persistence, secondary pollution, etc., and improve utilization The effect of increasing the rate, enhancing the adsorption capacity, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

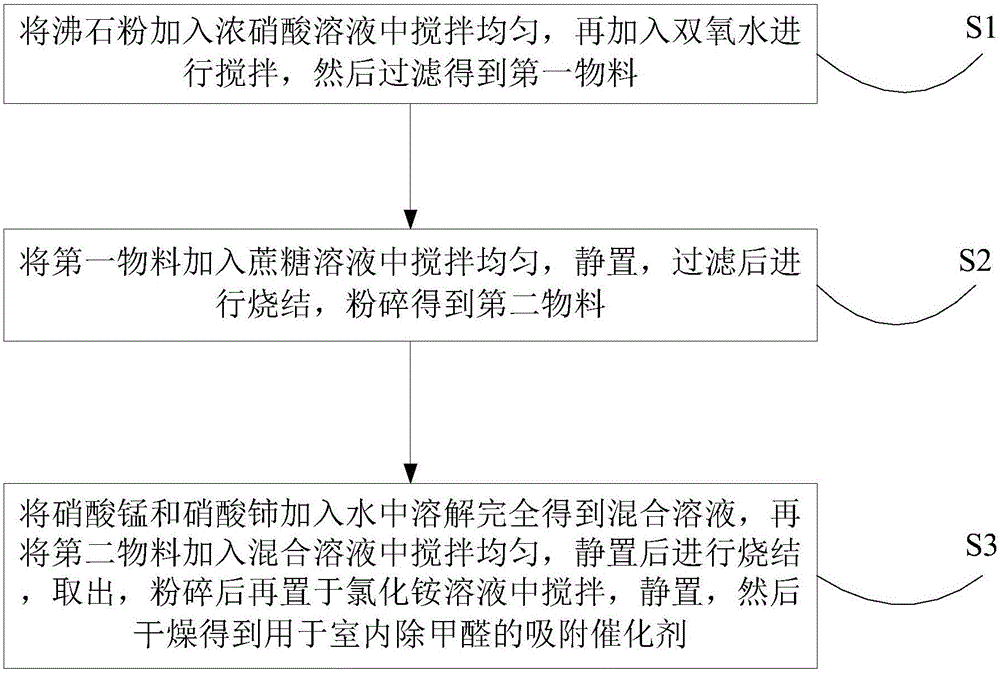

[0022] refer to figure 1 , a kind of preparation method that the present invention proposes is used for indoor removal formaldehyde adsorption catalyst, comprises the steps:

[0023] S1. Add zeolite powder into concentrated nitric acid solution and stir evenly, then add hydrogen peroxide for stirring, and then filter to obtain the first material;

[0024] S2. Add the first material into the sucrose solution, stir evenly, let stand, filter, sinter, and pulverize to obtain the second material;

[0025] S3, adding manganese nitrate and cerium nitrate into water to dissolve completely to obtain a mixed solution, then adding the second material into the mixed solution and stirring evenly, sintering after standing, taking out, pulverizing and then placing in ammonium chloride solution and stirring, and standing , and then dried to obtain an adsorption catalyst for indoor formaldehyde removal.

Embodiment 1

[0028] A kind of preparation method that the present invention proposes is used for indoor removal formaldehyde adsorption catalyst, comprises the steps:

[0029] S1. Add 45 parts of 200 mesh zeolite powder in parts by weight to 24 parts of concentrated nitric acid solution with a mass fraction of 68wt% and stir evenly, then add 80 parts of hydrogen peroxide with a mass fraction of 16wt% and stir for 2 hours. During the process of adding hydrogen peroxide and stirring , maintaining the temperature at 40°C, and then filtering to obtain the first material;

[0030] S2. Add 100 parts of the first material in parts by weight to 80 parts of sucrose solution with a mass fraction of 55wt%, stir evenly, let stand for 12 hours, filter and sinter at 440°C for 1.5 hours, and pulverize to obtain the first Two materials;

[0031] S3, adding manganese nitrate and cerium nitrate into water to dissolve completely to obtain a mixed solution, the concentration of manganese ions in the mixed so...

Embodiment 2

[0033] A kind of preparation method that the present invention proposes is used for indoor removal formaldehyde adsorption catalyst, comprises the steps:

[0034] S1. Add 55 parts of 160 mesh zeolite powder in parts by weight to 36 parts of concentrated nitric acid solution with a mass fraction of 65wt% and stir evenly, then add 88 parts of hydrogen peroxide with a mass fraction of 10wt% and stir for 4 hours. During the process of adding hydrogen peroxide and stirring , maintaining the temperature at 30°C, and then filtering to obtain the first material;

[0035] S2. Add 100 parts of the first material in parts by weight to 88 parts of sucrose solution with a mass fraction of 50wt%, stir evenly, let stand for 16 hours, filter and sinter at 400°C for 2 hours, and pulverize to obtain the second materials;

[0036] S3, adding manganese nitrate and cerium nitrate into water to dissolve completely to obtain a mixed solution, the concentration of manganese ions in the mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com