Rubbish-fly-ash and cement-kiln cooperation treatment method

A technology of co-processing and garbage fly ash, applied in the direction of solid waste removal, etc., can solve problems such as market irregularities, vicious competition, and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

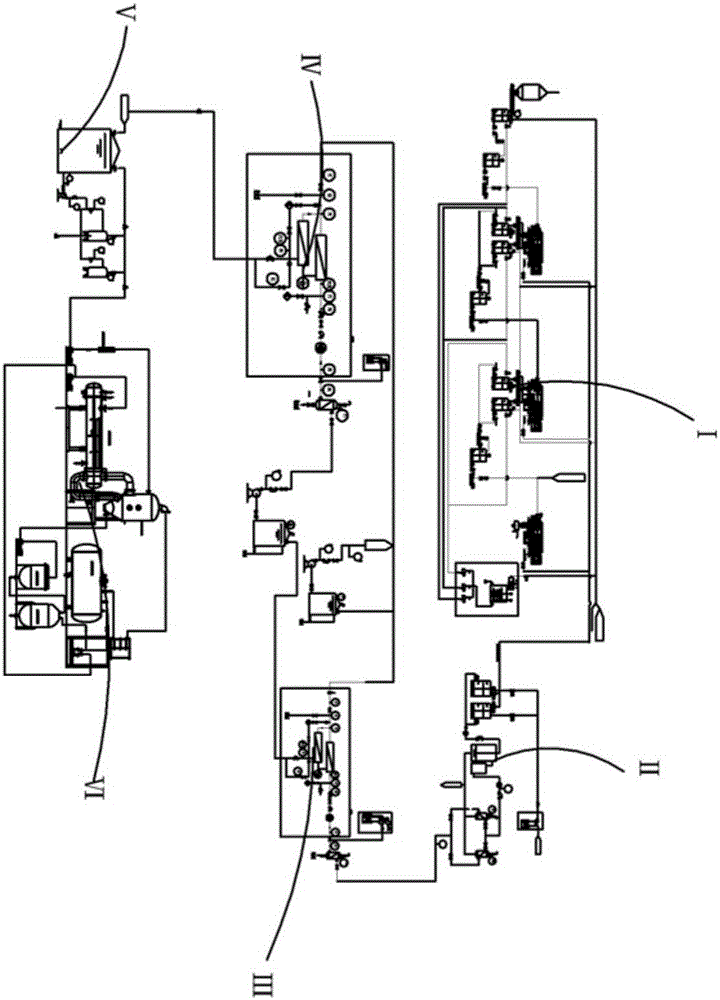

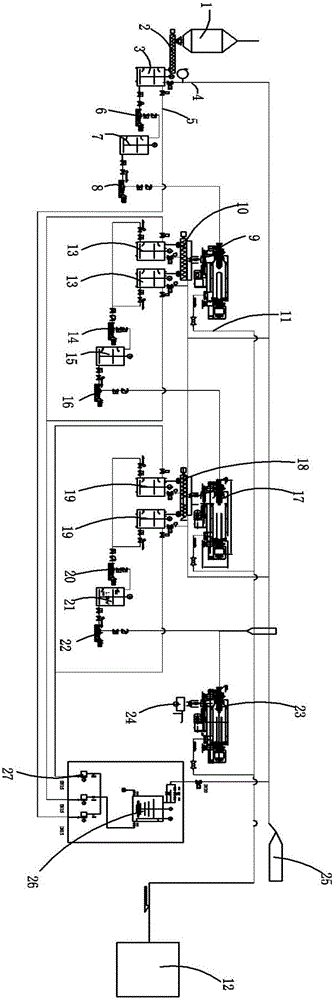

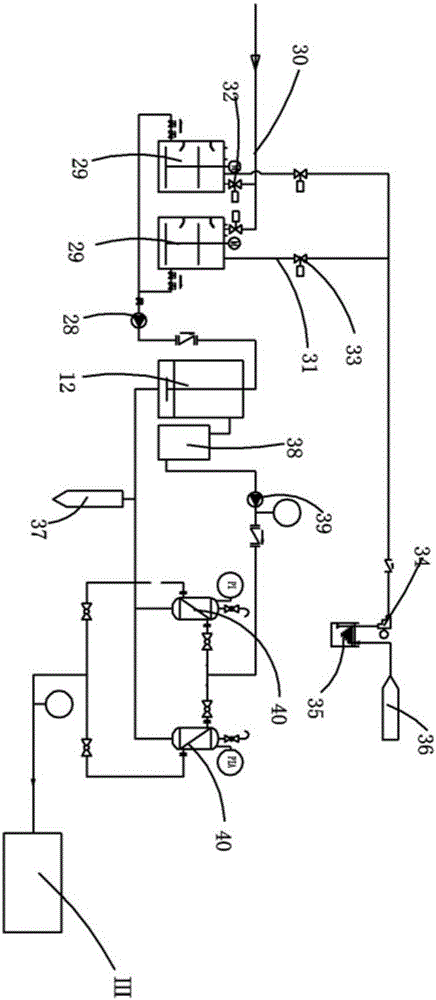

[0048] Examples, see attached Figure 1~6 , A method for co-processing garbage fly ash cement kiln, which includes the following process:

[0049] (1) Waste incineration fly ash tertiary water elution salt and microbial dioxin removal process;

[0050] (2) Bunch glue strengthens the heavy metal removal process;

[0051] (3) Nanofiltration process;

[0052] (4) Reverse osmosis pre-concentration process;

[0053] (5) Process for removing extremely trace impurities;

[0054] (6) MVR evaporation crystallization process.

[0055] The waste incineration fly ash tertiary water elution salt and microbial dioxin removal process includes the following steps: the process is completed by the waste incineration fly ash tertiary water elution salt and microbes dioxin removal device I.

[0056] a. Water washing: the waste incineration fly ash is blown from the fly ash storage 1 into the screw conveyor a2, enters the mixing tank a3 through the screw conveyor a, and a certain amount of water is added, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com