Green high-efficiency pollutant supercritical water oxidization method

A technology for supercritical water oxidation and pollutants, applied in the direction of water pollutants, chemical instruments and methods, separation methods, etc., can solve the problems of heat transfer/mass efficiency reduction, failure, blockage, etc., to reduce the content of inorganic salts, avoid The effect of deposition and efficient green operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

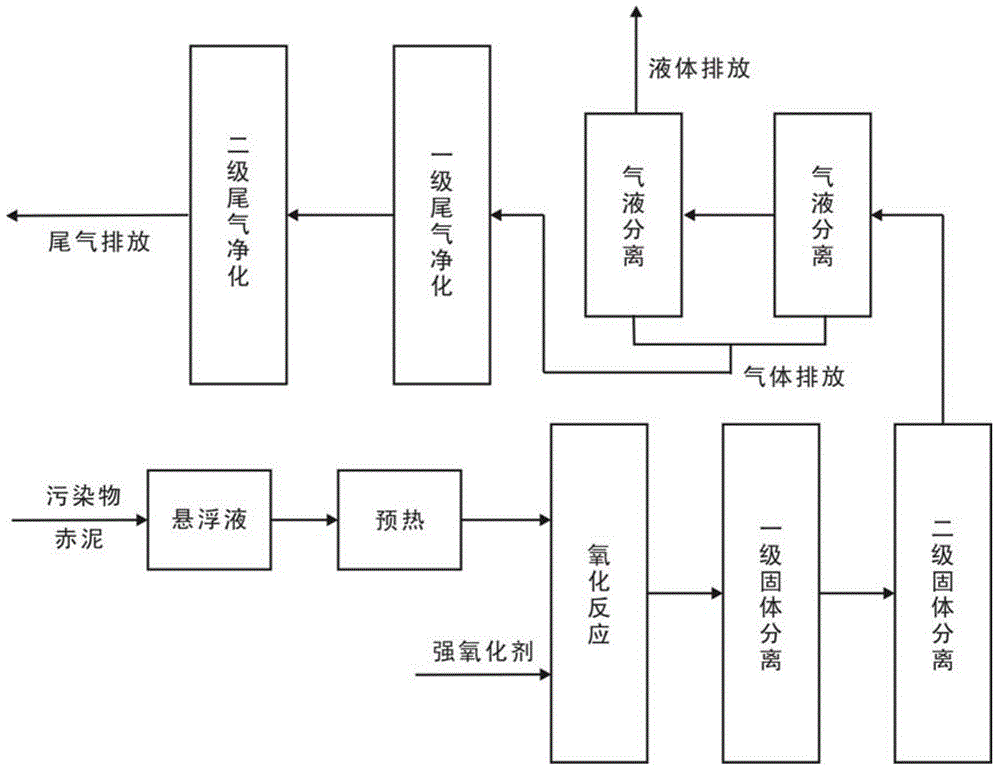

[0027] like figure 1 As shown, the nitrogen-containing toxic liquid pollutants are treated according to the following steps:

[0028] (1) Material preparation: Add nitrogen-containing toxic liquid pollutants into the storage tank, then start stirring, and then slowly add red mud solids into the storage tank to prepare a suspension with a mass ratio of red mud to pollutants of 0.05:1 liquid;

[0029] (2) Oxidation reaction: pump the suspension prepared in step (1) into the preheater, and the mixed material in the preheater is preheated to 150°C, and then directly pumped into the supercritical water oxidation reactor. In the reactor, the mixed material and the strong oxidant—air pumped into the reactor at the same time undergo oxidative degradation reaction. The temperature in the reactor is controlled at 450°C, the pressure is 24MPa, the residence time is 60 seconds, and the excess oxygen is the theoretical oxygen demand 50% of the amount (in moles);

[0030] (3) Solid separ...

Embodiment 2

[0035] (1) Material preparation: Add organic liquid pollutants containing sulfur and phosphorus to the storage tank, then start stirring, then slowly add red mud solids into the storage tank, and prepare a mass ratio of red mud to pollutants of 0.4:1 suspension;

[0036] (2) Oxidation reaction: The suspension prepared in step (1) is pumped into the preheater, and the mixed material in the preheater is preheated to 300°C, and then directly pumped into the supercritical water oxidation reactor. In the reactor, the mixed material and the strong oxidant - hydrogen peroxide pumped into the reactor at the same time undergo oxidative degradation reaction. The reaction temperature is controlled at 480°C, the pressure is 25MPa, the residence time is 80 seconds, and the peroxygen amount is 30% of the theoretical oxygen demand. % (in moles);

[0037] (3) Solid separation: the feed liquid after passing through the oxidation reactor enters the three-stage solid separator in series, and th...

Embodiment 3

[0042] (1) Material preparation: Add nitrogen-containing and sulfur-containing toxic liquid pollutants to the storage tank, then start stirring, and then slowly add red mud solids into the storage tank to prepare a mass ratio of red mud to pollutants of 0.2:1 suspension;

[0043] (2) Oxidation reaction: pump the suspension prepared in step (1) into the preheater, and the mixed material in the preheater is preheated to 200°C, and then directly pumped into the supercritical water oxidation reactor. In the reactor, the mixed material and the strong oxidant—oxygen pumped into the reactor at the same time undergo oxidative degradation reaction. The temperature in the reactor is controlled at 400°C, the pressure is 28MPa, the residence time is 15 seconds, and the excess oxygen is the theoretical oxygen demand 15% of the volume (by moles);

[0044] (3) Solid separation: The feed liquid after passing through the oxidation reactor enters the two-stage solid separator in series, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com