A kind of alumina roasting flue gas desulfurization and denitrification system and method and application

A desulfurization, denitrification and alumina technology, which is applied in the field of pollutant control, can solve the problems that waste cannot be effectively recycled, cannot be effectively simultaneously desulfurized and denitrified, and the desulfurization and denitration efficiency is low, so as to reduce ozone consumption and escape risks, overcome the The effect of difficult NO2 absorption and stable operation at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

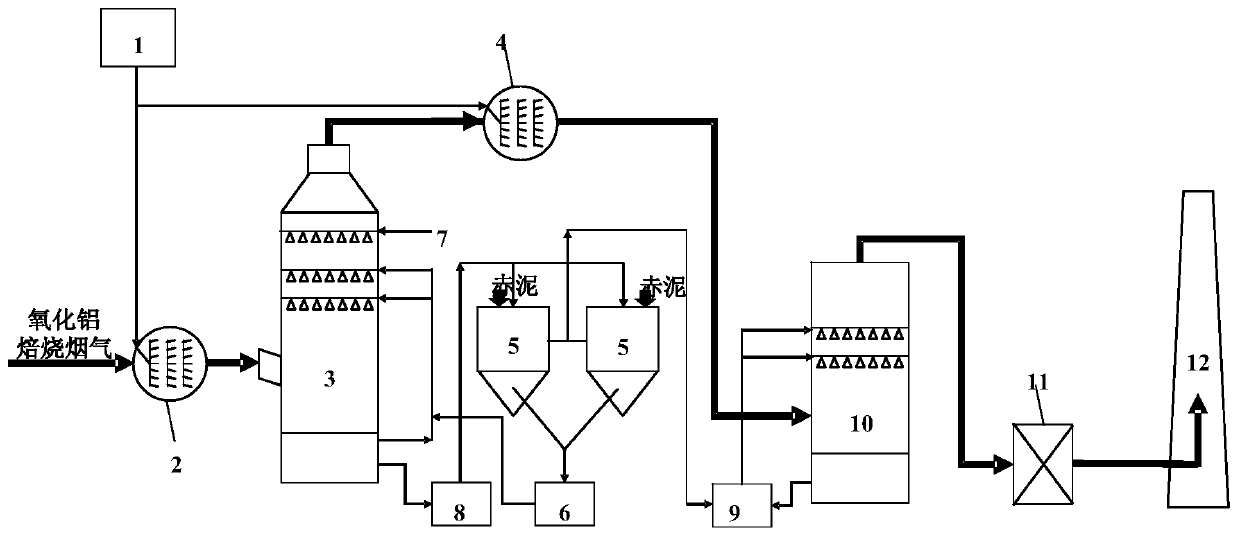

[0064] This embodiment provides an alumina roasting flue gas desulfurization and denitrification system, such as figure 1 As shown, the system includes an ozone generator 1, a first ozone uniform distributor 2, a red mud presoak slurry washing tower 3, a second ozone uniform distributor 4, a red mud presoak tank 5, and a red mud presoak slurry tank 6. Process water pipeline 7, dehydration tank 8, red mud pre-soaked liquid tank 9, red mud pre-soaked liquid washing tower 10, demister 11 and chimney 12;

[0065] Wherein, the upper part of the red mud presoaked slurry washing tower 3 is provided with a spray layer, and the tower wall below the spray layer is provided with a flue gas inlet to connect with the alumina roasting flue gas pipeline, and the alumina roasting flue gas pipeline is provided with a There is a first ozone uniform distributor 2; the upper part of the red mud presoaked liquid washing tower 10 is provided with a spray layer, and the tower wall below the spray la...

Embodiment 2

[0067] This example provides a method for desulfurization and denitrification of flue gas from alumina roasting, which is carried out by using the desulfurization and denitrification system of flue gas from alumina roasting described in Example 1, and desulfurization and denitrification of 500,000 tons / year alumina roasting furnace , SO in flue gas 2 The concentration is 250mg / m 3 , NO x The concentration is 500mg / m 3 .

[0068] Specifically include the following steps:

[0069] (a) Ozone produced in the ozone generator 1 is mixed in the flue gas of alumina roasting through the first ozone uniform distributor 2, wherein ozone and NO in the flue gas of alumina roasting x The molar ratio is 0.4:1, and the alumina roasting flue gas mixed with ozone is sent to the red mud pre-soaking slurry washing tower 3, and the slurry with a pH of 4 obtained after red mud pre-soaking from the red mud pre-soaking tank 5 is processed. Reverse spraying to obtain flue gas after primary treatm...

Embodiment 3

[0073] This embodiment provides a method for desulfurization and denitrification of flue gas from alumina roasting. The method is carried out by using the desulfurization and denitrification system of flue gas from alumina roasting described in Example 1. The treatment method refers to the method in Example 2. The only difference is: the steps (a) Ozone and NO in alumina roasting flue gas x The molar ratio is 0.8:1, the pH of the slurry obtained after red mud presoaking is 5, and the ozone and the remaining NO in the flue gas after primary treatment in step (b) x The molar ratio is 0.4:1, and the pH of the supernatant obtained after red mud presoaking is 9.

[0074] SO in the purified flue gas in this example 2 The concentration is 6mg / m 3 , NO x The concentration is 60mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com