Method for separating and purifying polysaccharides from winter jujubes

A technology for polysaccharide and winter jujube, applied in the field of purifying polysaccharide and separation, can solve the problems of low product purity and high energy consumption, and achieve the effects of high protein removal rate, less loss of polysaccharide, high decolorization rate and high retention rate of polysaccharide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

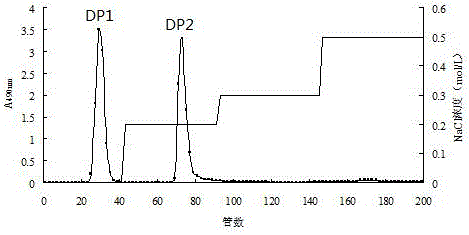

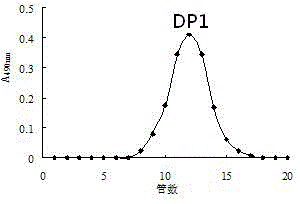

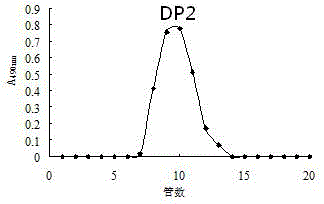

Image

Examples

Embodiment 1

[0028] A method for separating and purifying polysaccharides from winter jujube, comprising the following steps:

[0029] (1) Extraction of crude polysaccharides: The dried and crushed winter jujube powder was soaked at room temperature for 30 minutes according to the mass ratio of winter jujube powder to water at 1:25, and extracted with hot water to obtain crude polysaccharide extract and Filter residue: Concentrate the crude polysaccharide extract to 1 / 3 of the original volume to obtain a concentrated solution, add ethanol with a mass concentration of 95% to the concentrated solution for alcohol precipitation, add ethanol to a volume ratio of 3 times the concentrated solution, Alcohol precipitation for 6 hours, followed by centrifugation to obtain a crude polysaccharide precipitate of winter jujube, which was vacuum-dried at 60° C. to obtain a primary crude polysaccharide.

[0030] (2) Deproteinization: make the crude polysaccharide prepared in step (1) into a crude polysac...

Embodiment 2

[0036] A method for separating and purifying polysaccharides from winter jujube, comprising the following steps:

[0037] (1) Extraction of crude polysaccharides: The dried and crushed winter jujube powder was soaked at room temperature for 30 minutes according to the mass ratio of winter jujube powder to water at 1:20, and extracted with hot water to obtain the crude polysaccharide extract and Filter residue: Concentrate the crude polysaccharide extract to 1 / 2 of the original volume to obtain a concentrated solution, add ethanol with a mass concentration of 90% to the concentrated solution for alcohol precipitation, and add ethanol to the concentrated solution in a volume ratio of 2 times, Alcohol precipitation for 4 hours, followed by centrifugation to obtain the crude polysaccharide precipitate of winter jujube, which was vacuum-dried at 60° C. to obtain the primary crude polysaccharide.

[0038] (2) Deproteinization: make the crude polysaccharide prepared in step (1) into ...

Embodiment 3

[0044] A method for separating and purifying polysaccharides from winter jujube, comprising the following steps:

[0045] (1) Extraction of crude polysaccharides: The dried and crushed winter jujube powder was soaked at room temperature for 30 minutes according to the mass ratio of winter jujube powder to water at 1:30, and extracted with hot water to obtain the crude polysaccharide extract and Filter residue: Concentrate the crude polysaccharide extract to 1 / 4 of the original volume to obtain a concentrated solution, add ethanol with a mass concentration of 100% to the concentrated solution for alcohol precipitation, add ethanol to a volume ratio of 4 times the concentrated solution, Alcohol precipitation for 8 hours, followed by centrifugation to obtain the crude polysaccharide precipitate of winter jujube, which was vacuum-dried at 60° C. to obtain the primary crude polysaccharide.

[0046] (2) Deproteinization: make the crude polysaccharide prepared in step (1) into a crud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com