Biocompatible quantum dot light-emitting film and preparation method thereof

A quantum dot luminescent and biocompatible technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that thin films are difficult to maintain the optical properties of silicon quantum dots, hinder the solid-state application of silicon quantum dots, and quench the fluorescence of quantum dots. Achieve excellent luminous performance and optical stability, excellent luminous efficiency, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. A colloidal solution of silicon quantum dots with excellent optical properties that is stably dispersed in water is self-made in the laboratory;

[0023] 2. Prepare a hectorite aqueous solution with a mass fraction of 2%: weigh 0.2g of hectorite into a beaker, add 10ml of deionized water to fully dissolve;

[0024] 3. Mix 0.3ml of the bentonite aqueous solution obtained above with 50ml of silicon quantum dot colloidal solution, and stir thoroughly;

[0025] 4. Prepare 100ml of 3% sodium alginate aqueous solution, mix it with the above mixed solution, and stir thoroughly;

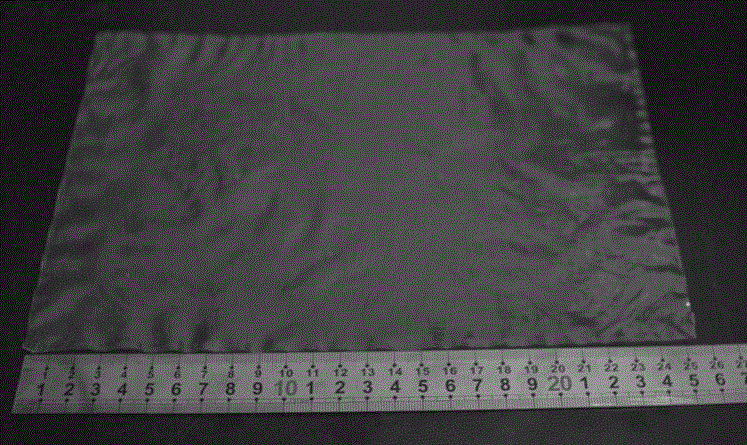

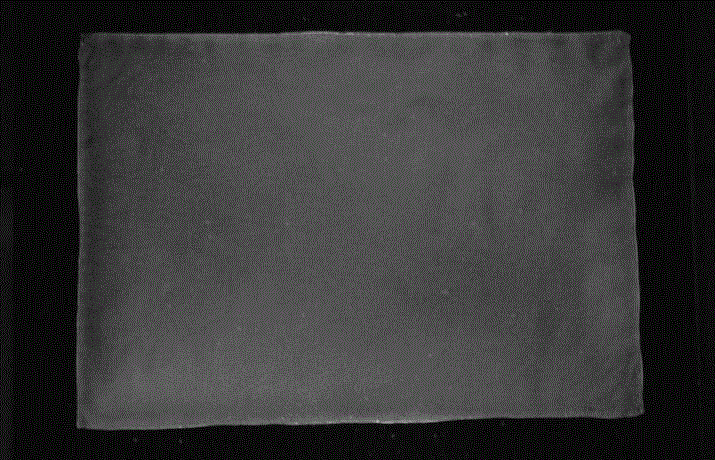

[0026] 5. Cast the obtained mixed solution on a mold with a size of 200mm×275mm, and place it in an environment with a temperature of about 25°C and a humidity of less than 40% for more than 24 hours;

[0027] 6. After the water evaporates completely, a film-like material with uniform texture, good luminescence performance and stability can be obtained.

Embodiment 2

[0029] 1. Obtain a carbon quantum dot colloidal solution with excellent optical properties that is stably dispersed in water through market purchase;

[0030] 2. Prepare a hectorite aqueous solution with a mass fraction of 2%: weigh 0.2g of hectorite into a beaker, add 10ml of deionized water to fully dissolve;

[0031] 3. Mix 0.3ml of the bentonite aqueous solution obtained above with 50ml of silicon quantum dot colloidal solution, and stir thoroughly;

[0032] 4. Prepare 100ml of 3% sodium alginate aqueous solution, mix it with the above mixed solution, and stir thoroughly;

[0033] 5. Cast the obtained mixed solution on a mold with a size of 200mm×275mm, and place it in an environment with a temperature of about 25°C and a humidity of less than 40% for more than 24 hours;

[0034] 6. After the water evaporates completely, a film-like material with uniform texture, good luminescence performance and stability can be obtained.

Embodiment 3

[0036] 1. A colloidal solution of silicon quantum dots with excellent optical properties that is stably dispersed in water is self-made in the laboratory;

[0037] 2. Prepare a montmorillonite aqueous solution with a mass fraction of 1%: weigh 0.1 g of montmorillonite powder into a beaker, add 10 ml of deionized water to fully dissolve;

[0038] 3. Mix 0.3ml of the bentonite aqueous solution obtained above with 50ml of silicon quantum dot colloidal solution, and stir thoroughly;

[0039] 4. Prepare 100ml of 3% sodium alginate aqueous solution, mix it with the above mixed solution, and stir thoroughly;

[0040] 5. Cast the obtained mixed solution on a mold with a size of 200mm×275mm, and place it in an environment with a temperature of about 25°C and a humidity of less than 40% for more than 24 hours;

[0041] 6. After the water evaporates completely, a film-like material with uniform texture, good luminescence performance and stability can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com