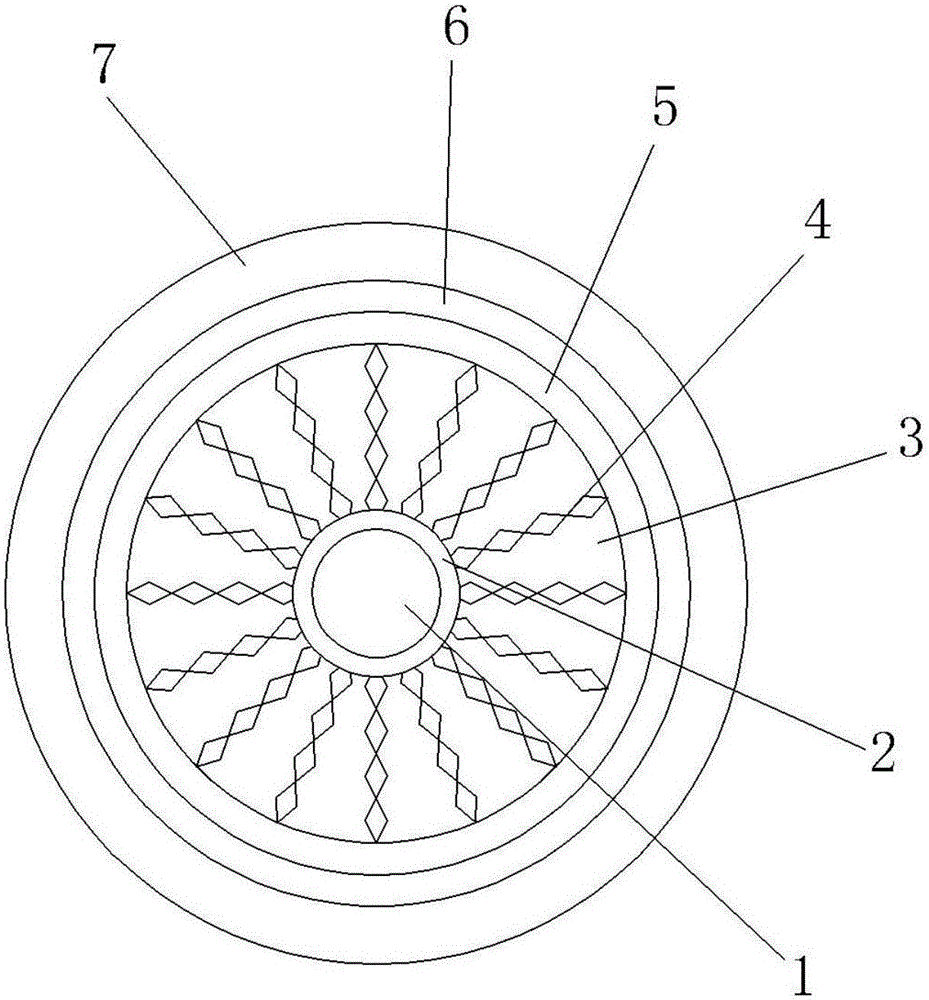

Anti-extrusion cable

An anti-extrusion, cable technology, applied in the field of power cables, can solve problems affecting the normal use of cables, cable aging, cable deformation, etc., to improve the overall extrusion resistance, improve extrusion resistance, and improve extrusion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The raw material of buffer plate 4 comprises by weight: 100 parts of natural rubber, 70 parts of neoprene, 55 parts of silicon rubber, 45 parts of styrene-butadiene rubber, 35 parts of butadiene rubber, 40 parts of nitrile rubber, 5.5 parts of zinc oxide, hard 3 parts of fatty acid, 8.5 parts of polyolefin elastomer, 3 parts of KH550 silane coupling agent, 4 parts of KH570 silane coupling agent, 8 parts of quinol ester, 4 parts of dicumyl peroxide, 3 parts of vulcanizing agent DCP, tetrachloride 5 parts of benzoquinone, 6 parts of accelerator DM, 7 parts of activated white carbon black, 6 parts of polyethylene glycol, 5 parts of dispersant CNF, 3 parts of anti-aging agent RD, 4 parts of anti-aging agent AW, N-cyclohexylthiophthaloyl 4 parts imine.

[0033] Among them, N-cyclohexylthiophthalimide is prepared according to the following process: 1 mol of dicyclohexyl disulfide is dissolved in cyclohexane to obtain material a, and at 10°C, feed 0.05 mol of chlorine gas, th...

Embodiment 2

[0035] The raw material of buffer plate 4 comprises by weight: 80 parts of natural rubber, 80 parts of neoprene, 40 parts of silicon rubber, 60 parts of styrene-butadiene rubber, 20 parts of butadiene rubber, 50 parts of nitrile rubber, 2 parts of zinc oxide, hard 5 parts of fatty acid, 5 parts of polyolefin elastomer, 5 parts of KH550 silane coupling agent, 2 parts of KH570 silane coupling agent, 10 parts of quinol ester, 2 parts of dicumyl peroxide, 5 parts of vulcanizing agent DCP, tetrachloride 2 parts of benzoquinone, 9 parts of accelerator DM, 2 parts of activated white carbon black, 9 parts of polyethylene glycol, 2 parts of dispersant CNF, 5 parts of antioxidant RD, 2 parts of antioxidant AW, N-cyclohexylthiophthaloyl 6 parts of imine.

[0036] Among them, N-cyclohexylthiophthalimide is prepared according to the following process: 1mol of dicyclohexyl disulfide is dissolved in cyclohexane to obtain material a, and the 0.03 mol of chlorine gas, then added 4 mol of phth...

Embodiment 3

[0038] The raw material of buffer plate 4 comprises by weight: 120 parts of natural rubber, 60 parts of neoprene, 70 parts of silicon rubber, 30 parts of styrene-butadiene rubber, 50 parts of butadiene rubber, 30 parts of nitrile rubber, 9 parts of zinc oxide, hard 1 part of fatty acid, 12 parts of polyolefin elastomer, 1 part of KH550 silane coupling agent, 6 parts of KH570 silane coupling agent, 6 parts of quinol ester, 6 parts of dicumyl peroxide, 1 part of vulcanizing agent DCP, tetrachloride 8 parts of benzoquinone, 3 parts of accelerator DM, 12 parts of activated white carbon black, 3 parts of polyethylene glycol, 8 parts of dispersant CNF, 1 part of anti-aging agent RD, 6 parts of anti-aging agent AW, N-cyclohexylthiophthaloyl 1 part imine.

[0039] Among them, N-cyclohexylthiophthalimide is prepared according to the following process: 1mol of dicyclohexyl disulfide is dissolved in cyclohexane to obtain material a, and 0.07 mol of chlorine, then add 1mol of phthalimide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com