Nitrile rubber seal ring and preparation method thereof

A technology of nitrile rubber and sealing rings, which is applied in the field of nitrile rubber sealing rings and its preparation, can solve the problems of poor tensile and compression resistance physical properties, easy aging, poor oil resistance and corrosion resistance of sealing rings, etc., and achieves Strong oil resistance, low preparation cost, and simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

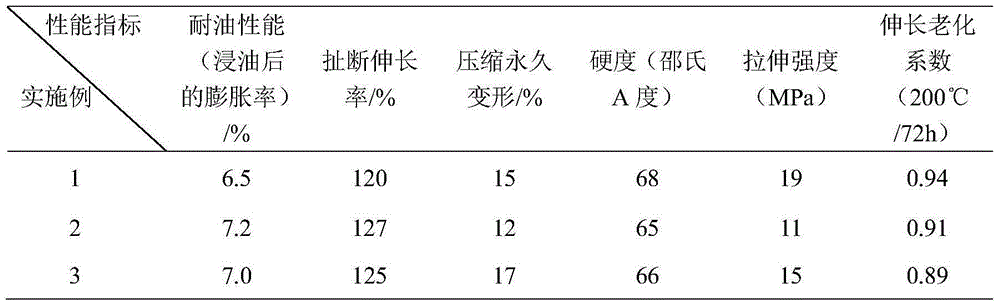

Embodiment 1

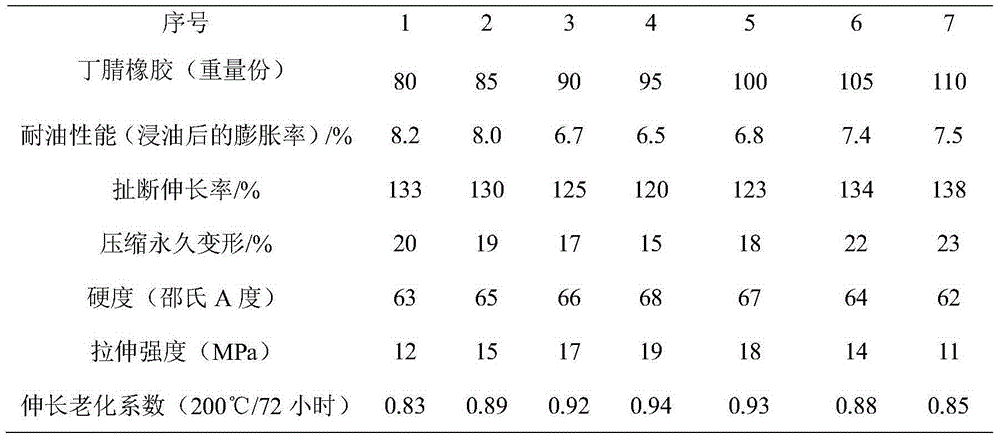

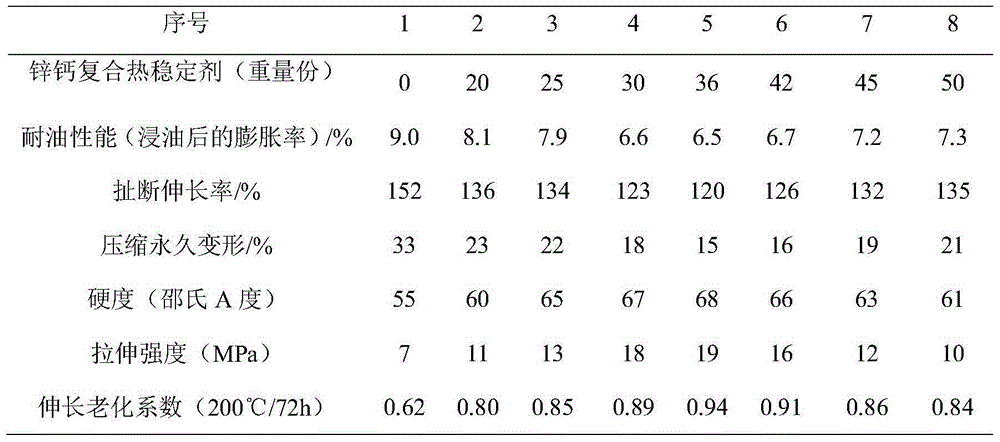

[0026] Raw materials: 95 parts of nitrile rubber, 36 parts of zinc-calcium composite heat stabilizer CH400, 1.5 parts of epoxy soybean oil, 2 parts of nano-calcium carbonate, 35 parts of carbon black, 400 parts of butanone, 2 parts of activated magnesium oxide, 5 parts of nano-zinc oxide 0.75 parts of sulfur, 0.7 parts of accelerator CZ, 2.5 parts of antioxidant RD, and 8 parts of tannic acid.

[0027] Preparation method: According to the above formula, first put nitrile rubber and methyl ethyl ketone into the internal mixer for 3min plastication, then add carbon black, epoxy soybean oil and sulfur, knead for 6min, unload, cool to room temperature and put into the open mixer In the process, put other constituent raw materials into the open mill and fully mix to obtain the mixed rubber. After vulcanizing for 125s under the condition of 155°C, it is processed and shaped to obtain the nitrile rubber sealing ring.

Embodiment 2

[0029] Raw materials: 90 parts of nitrile rubber, 42 parts of zinc-calcium composite heat stabilizer CH40142, 0.8 parts of epoxy soybean oil, 3 parts of clay, 25 parts of high wear-resistant white carbon black, 500 parts of methyl isobutyl ketone, 3 parts of activated magnesium oxide , 8 parts of nano-zinc oxide, 1 part of sulfur, 0.6 parts of accelerator CZ, 3 parts of anti-aging agent RD, 7 parts of tannic acid.

[0030] Preparation method: According to the above formula, first put nitrile rubber and methyl isobutyl ketone into the internal mixer for plasticizing for 5 minutes, then add high wear-resistant white carbon black, epoxy soybean oil and sulfur, knead for 5 minutes, unload and cool Put it into the open mill at room temperature, put other constituent raw materials into the open mill and fully mix to obtain the mixed rubber, vulcanize at 160°C for 100s, and then process it to obtain the nitrile rubber sealing ring.

Embodiment 3

[0032] Raw materials: 100 parts of nitrile rubber, 30 parts of zinc-calcium composite heat stabilizer CH40230, 2.5 parts of epoxy soybean oil, 1 part of calcium silicate, 40 parts of carbon black, 300 parts of ethyl acetate, 1 part of activated magnesium oxide, nanometer zinc oxide 3 parts, 0.5 parts of sulfur, 0.8 parts of accelerator CZ, 2 parts of antioxidant RD, 10 parts of tannic acid.

[0033] Preparation method: According to the above formula, first put nitrile rubber and ethyl acetate into the internal mixer for plasticizing for 4 minutes, then add carbon black, epoxy soybean oil and sulfur, knead for 7 minutes, unload, cool to room temperature and put into refining In the machine, put other raw materials into the open mill and fully mix to obtain the mixed rubber. After vulcanizing at 150°C for 150 seconds, it is processed and shaped to obtain the nitrile rubber sealing ring.

[0034] "Ethyl acetate" in the above examples can also be replaced with "butyl acetate", and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com