A kind of electrical energy storage dielectric ceramic/polymer composite material and preparation method thereof

A technology of composite materials and dielectric ceramics, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problem that the energy storage performance of ceramic/polymer composite materials will not be significantly improved, and achieve improved Dielectric breakdown field strength, high electrical energy storage density, and the effect of avoiding breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

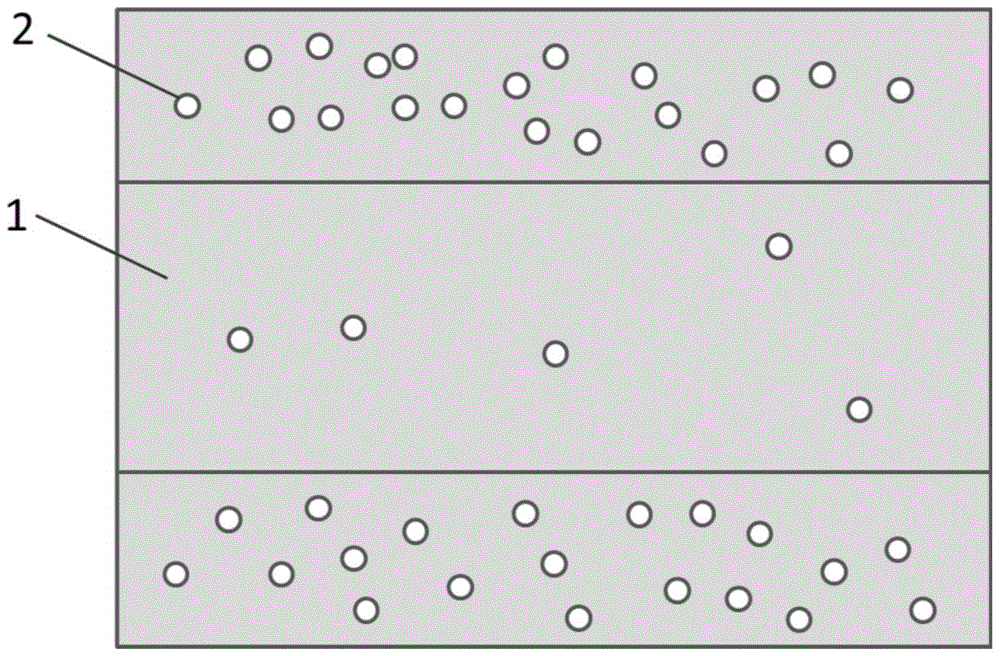

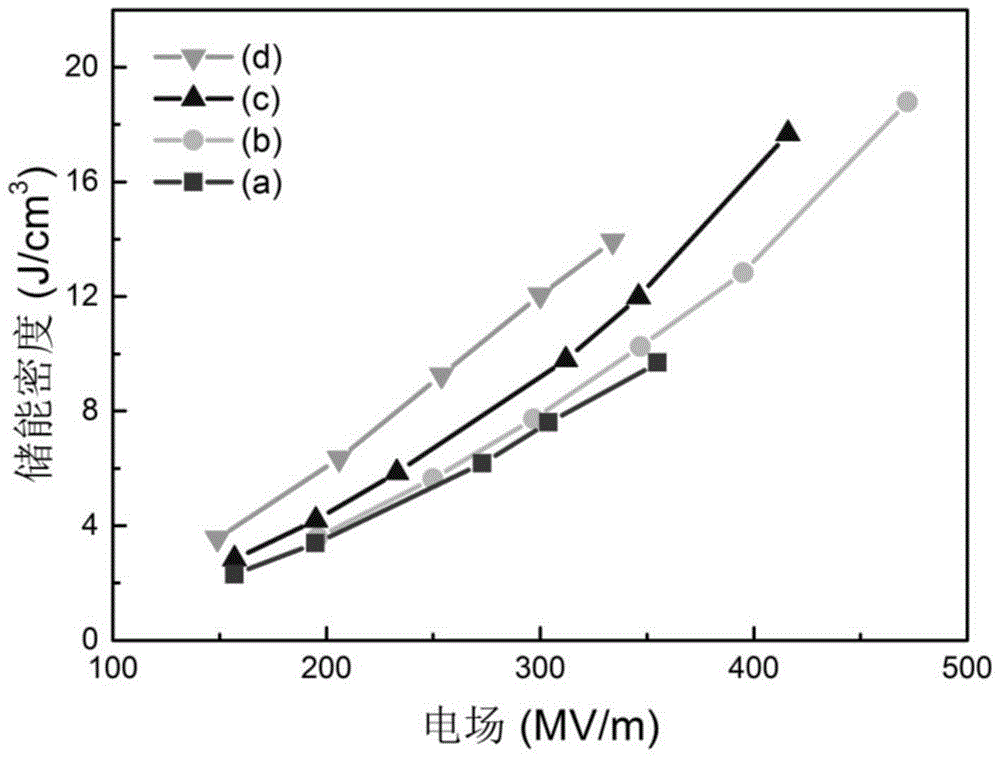

[0033] In this embodiment, polyvinylidene fluoride (PVDF) is used as the matrix, and nano barium titanate (BaTiO 3 ) particles (particle diameter less than 500 nanometers) are fillers. In this embodiment, the volume fraction of the filler in the upper and lower layers of the electrical energy storage medium ceramic / polymer composite is 10%, and the volume fraction of the filler in the middle layer is 1%. The overall thickness of the composite material is 20 microns, wherein the lower layer is 5 microns thick, the middle layer is 10 microns thick, and the upper layer is 5 microns thick.

[0034] The preparation method of the electric energy storage medium ceramic / polymer composite material is as follows:

[0035] 1) Weigh three parts of PVDF and dissolve them in three parts of mixed solvents of acetone and butanone respectively by magnetic stirring to obtain three parts of polymer solutions, wherein the mass ratio of polymer to solvent in each part of polymer solution is 1:10...

Embodiment 2

[0042] In this embodiment, polyvinylidene fluoride (PVDF) is used as the matrix, and nano barium titanate (BaTiO 3 ) particles (particle diameter less than 500 nanometers) are fillers. In this embodiment, the volume fraction of the filler in the upper and lower layers of the electric energy storage medium ceramic / polymer composite material is 20%, and the volume fraction of the filler in the middle layer is 1%. The overall thickness of the composite material is 20 microns, wherein the lower layer is 5 microns thick, the middle layer is 10 microns thick, and the upper layer is 5 microns thick.

[0043] The preparation method of the electric energy storage medium ceramic / polymer composite material is as follows:

[0044] 1) Weigh three parts of PVDF and dissolve them in three parts of mixed solvents of acetone and butanone respectively by magnetic stirring to obtain three parts of polymer solutions, wherein the mass ratio of polymer to solvent in each part of polymer solution i...

Embodiment 3

[0051] In this embodiment, polyimide (PI) is used as the matrix, and nano-titanium dioxide (TiO 2 ) particles (particle diameter less than 500 nanometers) are fillers. In this embodiment, the volume fraction of the filler in the upper and lower layers of the electrical energy storage medium ceramic / polymer composite is 10%, and the volume fraction of the filler in the middle layer is 1%. The overall thickness of the composite material is 20 microns, wherein the lower layer is 5 microns thick, the middle layer is 10 microns thick, and the upper layer is 5 microns thick.

[0052] The preparation method of the electric energy storage medium ceramic / polymer composite material is as follows:

[0053] 1) Weigh three parts of PI, and use magnetic stirring to dissolve it in three parts of dimethylformamide respectively to obtain three parts of polymer solutions, wherein the mass ratio of polymer to solvent in each part of polymer solution is 1: 20. The time for stirring and dissolvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com