Antistatic silicon rubber and preparation method thereof

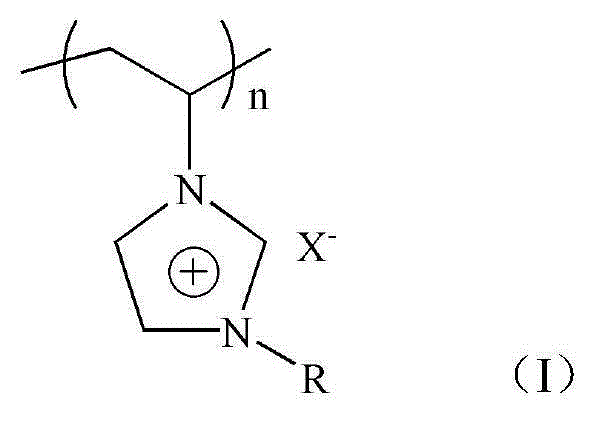

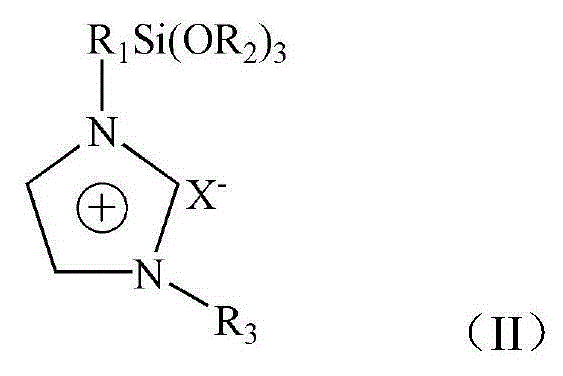

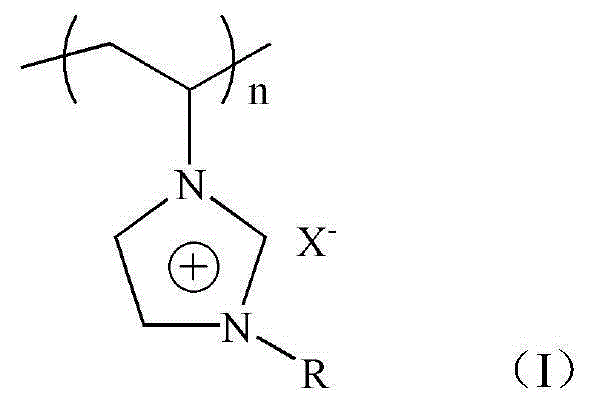

A silicone rubber and antistatic technology, applied in the field of silicone rubber and its preparation, can solve the problems of poor compatibility, difficult to last antistatic effect, uneven dispersion of antistatic agents, etc., and achieve good antistatic performance and stable antistatic performance. Long-lasting, excellent antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 100 parts of methyl vinyl silicone rubber raw rubber, 7 parts of 1-vinyl-3-propyl imidazolium chloride salt polymer, 40 parts of fumed white carbon black, 20 parts of calcium silicate, 20 parts of hexamethyldisilazane parts, platinum catalyst 3 parts.

[0053] The preparation method of the antistatic silicone rubber of the present embodiment comprises the following steps:

[0054] (1) 1-vinyl-3-propylimidazolium chloride salt polymer is dissolved in caprolactone to make antistatic agent mother liquor;

[0055] (2) Preparation of rubber compound: the antistatic agent mother liquor prepared in methyl vinyl silicone rubber raw rubber, fumed silica, calcium silicate, hexamethyldisilazane and step (1) is added to In a vacuum kneader, knead at room temperature for 0.5h, then raise the temperature to 150°C, knead in a vacuum for 4h, then add a platinum catalyst to the mixed silicone rubber and knead evenly on an open mill to obtain a silicone rubber compound ;

[0056] (3) ...

Embodiment 2

[0065] 100 parts of methyl vinyl silicone rubber raw rubber, 7 parts of 1-vinyl-3-methylimidazolium dicyanamide salt polymer, 20 parts of precipitated white carbon black, 5 parts of diphenylsilanediol, 2,5 1.8 parts of dimethyl-2,5-bis(t-butylperoxy)hexane.

[0066] The steps of the preparation method of the antistatic silicone rubber in this embodiment are the same as those in Example 1, and the raw materials and dosage are changed to the raw materials and dosage of the above formula.

Embodiment 3

[0071] 100 parts of dimethyl silicone rubber raw rubber, 4 parts of 1-vinyl-3-ethylimidazole hexafluorophosphate polymer, 20 parts of fumed white carbon black, 8 parts of cyclic trisilazane, bis( 2,4-dichlorobenzoyl) 0.5 parts, zinc stearate 0.1 parts.

[0072] The preparation method of the antistatic silicone rubber of the present embodiment comprises the following steps:

[0073] (1) 1-vinyl-3-propylimidazolium chloride salt polymer is dissolved in propylene carbonate to make antistatic agent mother liquor;

[0074] (2) Preparation of rubber compound: the antistatic agent mother liquor prepared in dimethyl silicone rubber, fumed silica, cyclic trisilazane, zinc stearate and step (1) is added to the vacuum In the kneader, knead at room temperature for 0.5h, then raise the temperature to 160°C, knead in a vacuum for 2h, then add bis(2,4-dichlorobenzoyl) vulcanizing agent to the above-mentioned mixed silicone rubber Mix evenly on the open mill to obtain silicone rubber compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com