Self-cleaning nano coating

A coating and self-cleaning technology, applied in the direction of anti-fouling/underwater coatings, radiation-absorbing coatings, coatings, etc., to achieve the effect of reducing the contact area, reducing the residence time, and prolonging the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

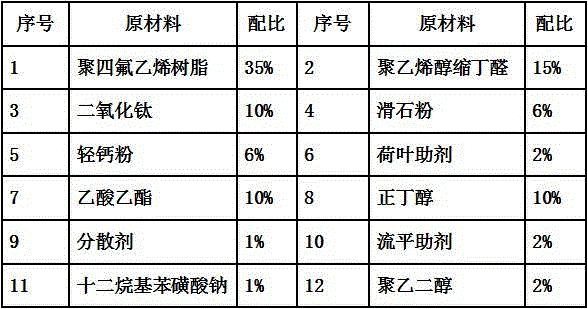

[0020] 1. First use a part of ethyl acetate and n-butanol to adjust the concentration of polytetrafluoroethylene resin and polyvinyl butyral, adjust to apply four cups for 25 seconds, and then seal the high temperature chelation. The temperature of chelation is 150 ℃, and the time 60 minutes. After cooling, the viscosity of the solution will increase, turn on the stirring, and then add some ethyl acetate and n-butanol to dilute to adjust the viscosity.

[0021] 2. Add various additives to the resin solution, stir, and then add titanium dioxide, talc powder, and light calcium powder in turn and stir. The stirring speed should reach 5000 rpm, high-speed stirring, and the stirring time should be more than 30 minutes.

[0022] 3. Finally, add the remaining various additives and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com