Shock-absorbing and lubricating coating for buildings and preparation method and applying method of shock-absorbing and lubricating coating

A technology for buildings and coatings, applied in the field of coatings, can solve the problems of difficult to replace the service life, high cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

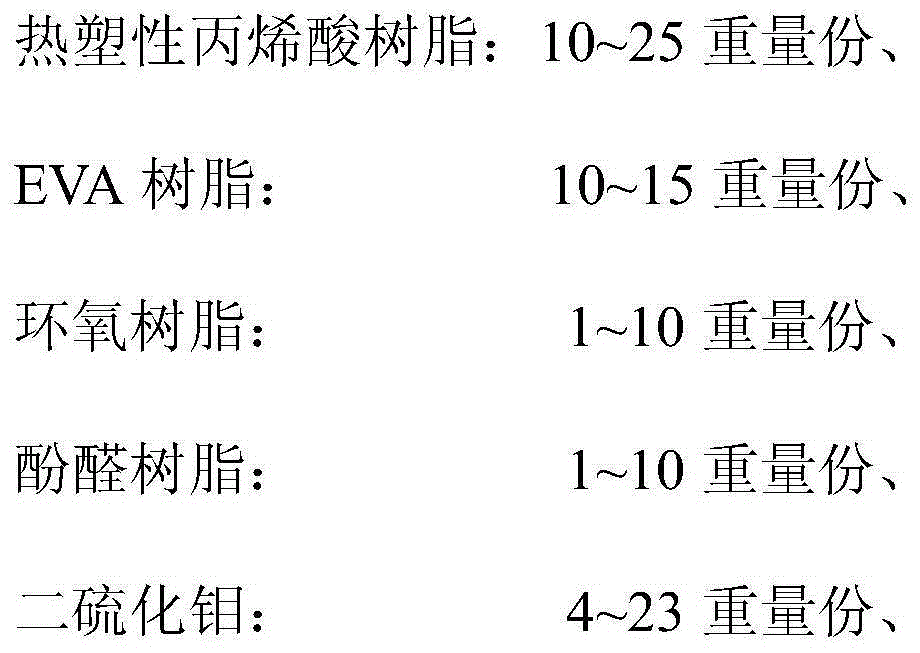

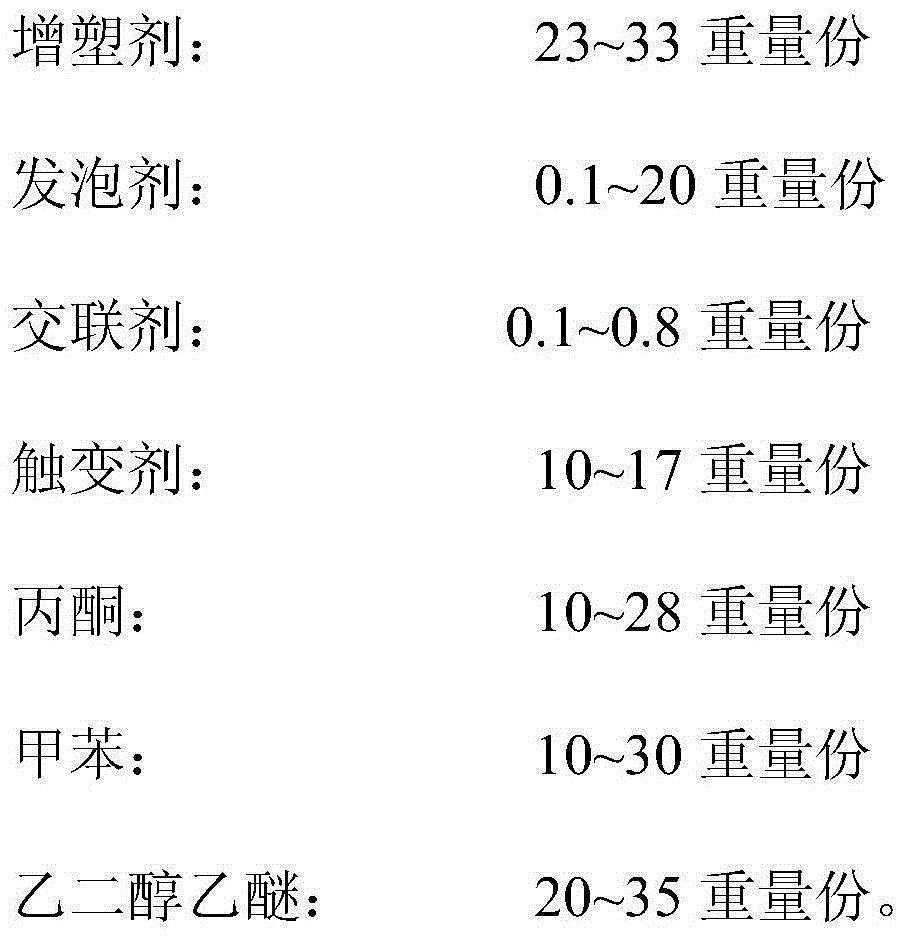

Method used

Image

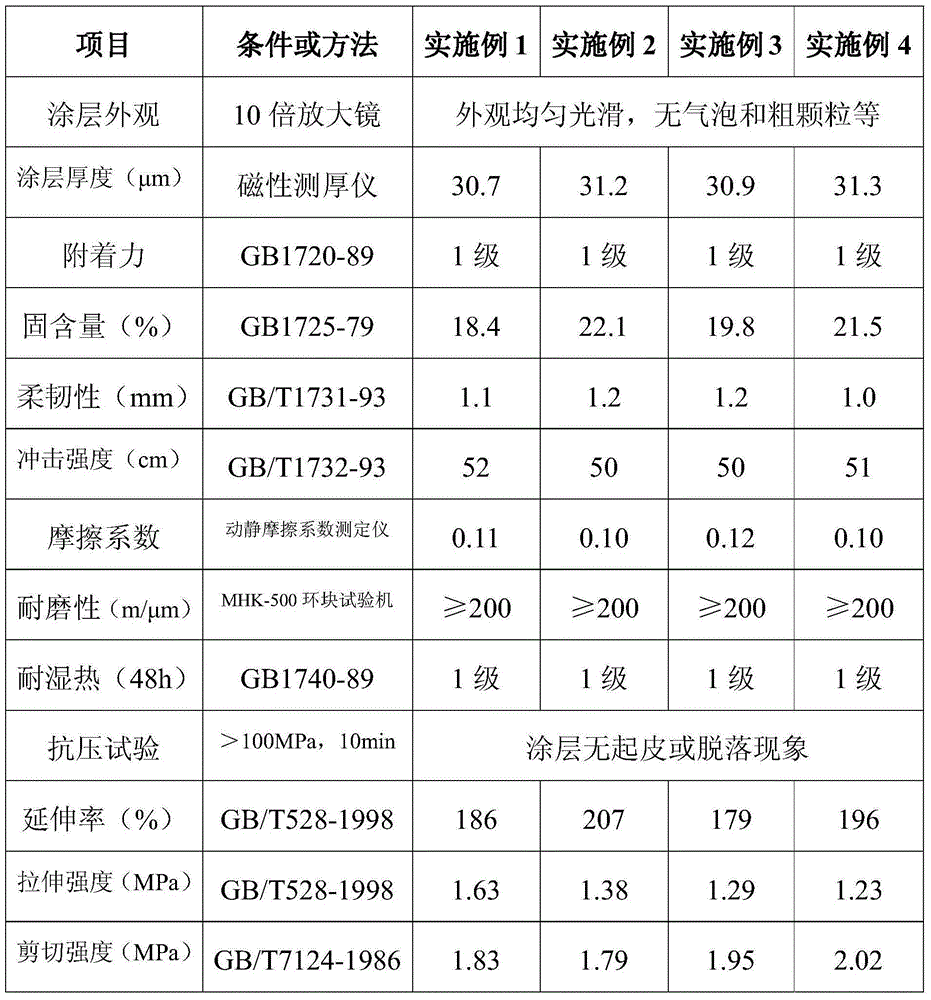

Examples

Embodiment 1

[0055] Preparation: (1) Put thermoplastic acrylic resin and EVA resin into a ball mill jar, add 3% of the total amount of mixed solvent to grind;

[0056] (2) adding 21.3% of the total weight of epoxy resin, phenolic resin, molybdenum disulfide, organosilane coupling agent and mixed solvent to grind;

[0057] (3) Add all the remaining mixed solvent into the ball mill tank, and mix evenly to obtain the shock-absorbing lubricating coating.

[0058] Coating: (1) Pre-degrease and derust the surface of the shock-absorbing support of the building;

[0059] (2) Spray the prepared paint on the surface of the building's shock-absorbing support under compressed air or compressed nitrogen, and place it in the air at room temperature for 8 hours;

[0060] (3) Curing: use a blower box, blow at a constant temperature of 147°C for 45 minutes; then blow at a constant temperature of 175°C for 90 minutes; the coating is completed.

Embodiment 2

[0062] Preparation: (1) Put thermoplastic acrylic resin and EVA resin into a ball mill jar, add 7% of the total amount of mixed solvent to grind;

[0063] (2) adding 17.5% of the total weight of epoxy resin, phenolic resin, molybdenum disulfide, organosilane coupling agent and mixed solvent to grind;

[0064] (3) Add all the remaining mixed solvent into the ball mill tank, and mix evenly to obtain the shock-absorbing lubricating coating.

[0065] Coating: (1) Pre-degrease and derust the surface of the shock-absorbing support of the building;

[0066] (2) Spray the prepared paint on the surface of the building's shock-absorbing support under compressed air or compressed nitrogen, and place it in the air at room temperature for 5 hours;

[0067] (3) Curing: use a blower box, blow at a constant temperature of 153°C for 30 minutes; then blow at a constant temperature of 185°C for 60 minutes; the coating is completed.

Embodiment 3

[0069] Preparation: (1) Put thermoplastic acrylic resin and EVA resin into a ball mill jar, add 5% of the total amount of mixed solvent to grind;

[0070] (2) adding 10% of the total weight of epoxy resin, phenolic resin, molybdenum disulfide, organosilane coupling agent and mixed solvent to grind;

[0071] (3) Add all the remaining mixed solvent into the ball mill tank, and mix evenly to obtain the shock-absorbing lubricating coating.

[0072] Coating: (1) Pre-degrease and derust the surface of the shock-absorbing support of the building;

[0073] (2) Spray the prepared paint on the surface of the building's shock-absorbing support under compressed air or compressed nitrogen, and place it in the air at room temperature for 10 hours;

[0074] (3) Curing: use a blower box, blow at a constant temperature of 150°C for 38 minutes; then blow at a constant temperature of 180°C for 75 minutes; the coating is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com