Bacterial complex for high-temperature composting of municipal solid wastes and production method thereof

A technology for municipal solid waste and compound inoculum, applied in the field of compound microbial inoculants, can solve the problems of low degradation rate of complex compounds, long composting cycle, poor competitiveness, etc., to shorten the composting cycle, improve compost quality, and stabilize the effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation of composite bacterial agent

[0025](1) Incline culture of single strains: under sterile conditions, inoculate Clostridium thermocellum, Thermotoga maritima, Bacillus subtilis, Bacillus stearothermophilus, Bacillus thermotolerant and actinomycetes on LB solid On the culture medium, culture in a constant temperature incubator at 60°C for 2 days;

[0026] (2) Primary seed cultivation: under sterile conditions, inoculate the strains cultivated in step (1) into LB liquid medium respectively, and vibrate at 200 rpm at 60°C for 2-5 days to obtain primary seeds;

[0027] (3) Expanded cultivation of secondary seeds: under aseptic conditions, the primary seeds prepared in step (2) are respectively expanded and cultivated at an inoculum size of 5-10% (v / v), and cultured by shaking at 200 rpm under 60°C for 3 -6d, to produce high-density cultured secondary seeds.

[0028] (4) Bacterial agent preparation: dehydrate and dry various secondary single b...

Embodiment 2

[0029] Example 2 Degradation experiment of triangular flask garbage using meal waste and corn stalks as main raw materials

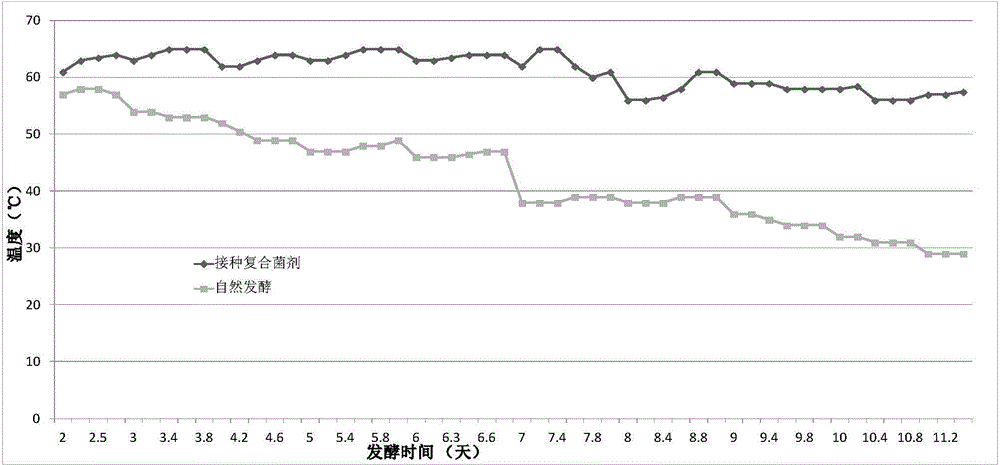

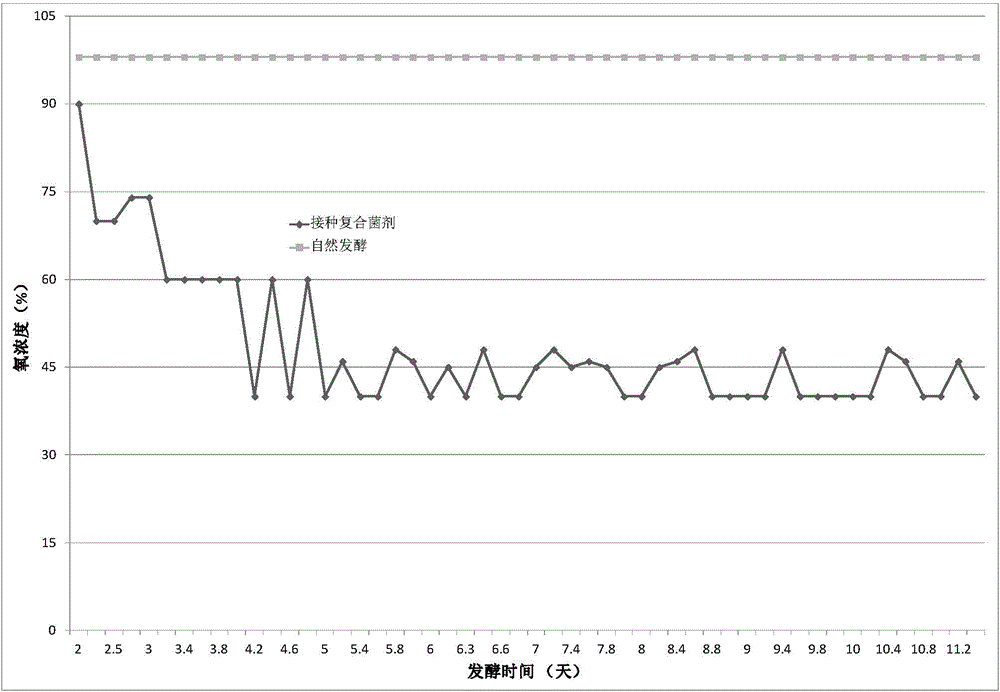

[0030] 100g of sorted meal waste, 100g of corn stalk scraps, after mixing, adjust the moisture to make the moisture content of the material 55%, add 1g of compound high-temperature bacteria agent and stir evenly, heat up to 65°C and run for 3 days. The results showed that within 3 days, the soybean products and meat products in the food waste were rapidly degraded after adding the high-temperature compound bacterial agent, among which the crude fiber, crude fat and crude protein were degraded by 11.5%, 15.6% and 40.0% respectively. The contents of the three in the high-temperature compound bacterial agent group were almost unchanged. The fermentation temperature of the high-temperature composite bacterial agent group was always maintained at 55-65°C, while the fermentation temperature of the non-inoculated group gradually decreased to about 30°C with tim...

Embodiment 3

[0031] Embodiment 3 is the compost of main raw material with municipal solid waste

[0032] Firstly, the raw garbage is manually sorted, and organic solids such as cartons, plastic products, metals, and stones are removed to obtain organic domestic waste, which mainly includes vegetable and fruit waste, kitchen waste, waste paper, and garden waste. Add 0.5% high-temperature composite microbial agent, add water to adjust the moisture content of the compost material to about 50%, and compost after fully stirring with a mixer. Turn over every 3-4 days depending on the change of fermentation temperature. The leachate produced during the fermentation process is refilled into the compost, and the compost is fermented at 65°C for 10-15 days to mature. It was measured that the organic matter content decreased by 58.2%, the cellulose content decreased by 40.0%, the hemicellulose content decreased by 55.4%, and the lignin content decreased by 32.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com