A kind of magnesium or magnesium alloy surface treatment method that can control the degradation rate

A technology for surface treatment and control of degradation, applied in the field of surface treatment of magnesium or magnesium alloys, can solve the problems of fast hydrogen evolution, affecting clinical treatment effects and human health, and excessive degradation, so as to achieve controllability and biodegradation The effect of speed, surface treatment method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Coating treatment of medical magnesium-calcium alloy

[0033] 1. Pretreatment: Use sandpaper to grind the medical magnesium-calcium alloy, and then use 1μm and 0.3μm Al 2 O 3 Polished with polishing powder, then ultrasonically cleaned the polished magnesium-calcium alloy in absolute ethanol for 5-10 min, and cleaned with N 2 Blow-dry; soak the dried magnesium-calcium alloy in a NaOH solution with a mass fraction of 20% for 24h, then wash it with deionized water, N 2 Blow dry.

[0034] 2. Preparation of mussel protein solution: before use, the mussel protein was diluted to 1 mg / mL with 1% citric acid buffer solution, and its pH was adjusted to 4.6 with NaOH solution, for use.

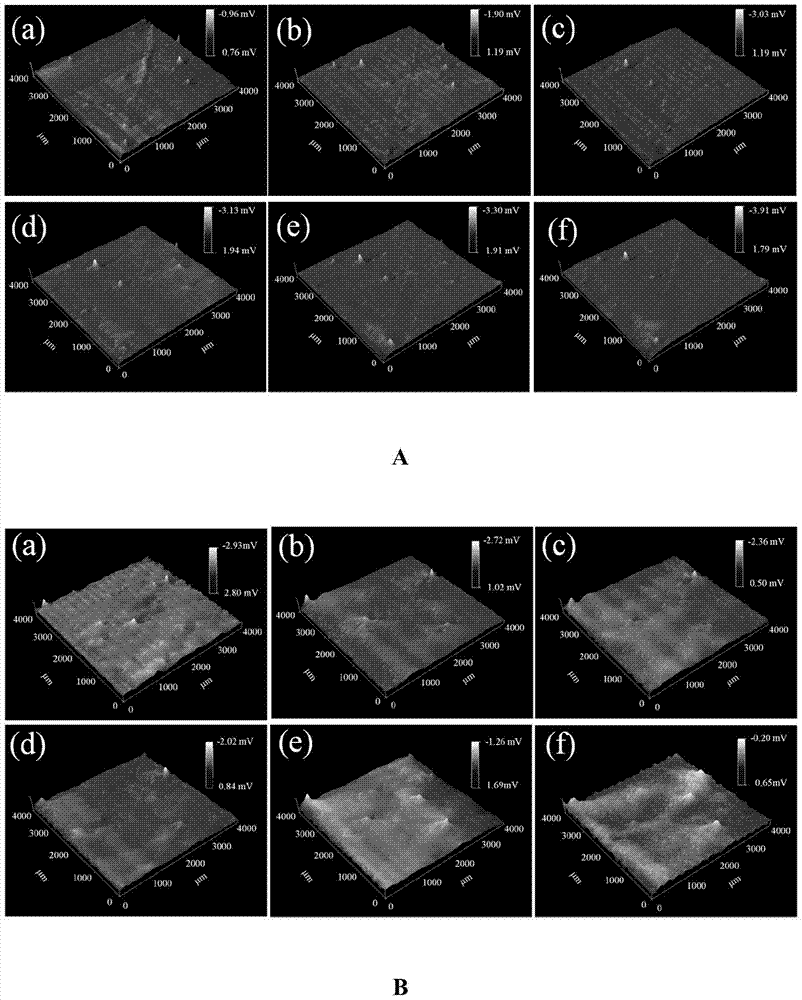

[0035] 3. Soak the magnesium-calcium alloy pretreated in step 1 in the mussel protein solution of step 2 for 1 hour, so that the mussel protein can be fully adsorbed on the surface of the magnesium-calcium alloy to form a protein film layer with a thickness of about 3-5 μm .

[0036...

Embodiment 2

[0037] Example 2 Coating treatment of medical magnesium-calcium alloy

[0038]1. Pretreatment: Use sandpaper to grind the medical magnesium-calcium alloy, and then use 1μm and 0.3μm Al 2 O 3 Polished with polishing powder, and then ultrasonically cleaned the polished magnesium-calcium alloy in absolute ethanol for 5-10 min, and cleaned with N 2 Blow-dry; soak the dried magnesium-calcium alloy in a NaOH solution with a mass fraction of 20% for 24h, then wash it with deionized water, N 2 Blow dry.

[0039] 2. Preparation of mussel protein solution and nano-cerium oxide solution: before use, dilute the mussel protein to 1 mg / mL with 1% citrate buffer solution, adjust its pH to 4.6 with NaOH solution, and use it for later use; Deionized water was prepared with a nano-cerium oxide solution with a concentration of 500 ppm.

[0040] 3. Soak the magnesium-calcium alloy pretreated in step 1 in the mussel protein solution of step 2 for 1 hour, and then soak it in the nano-cerium oxi...

Embodiment 3

[0043] In step 3, the magnesium-calcium alloy was soaked in the mussel protein solution for 1 hour and coated with a layer of protein film, then air-dried for 2 hours, and then the second layer of protein film was coated according to the same operation, and other steps were the same as in Example 1, A double protein film layer is formed on the surface of the magnesium-calcium alloy.

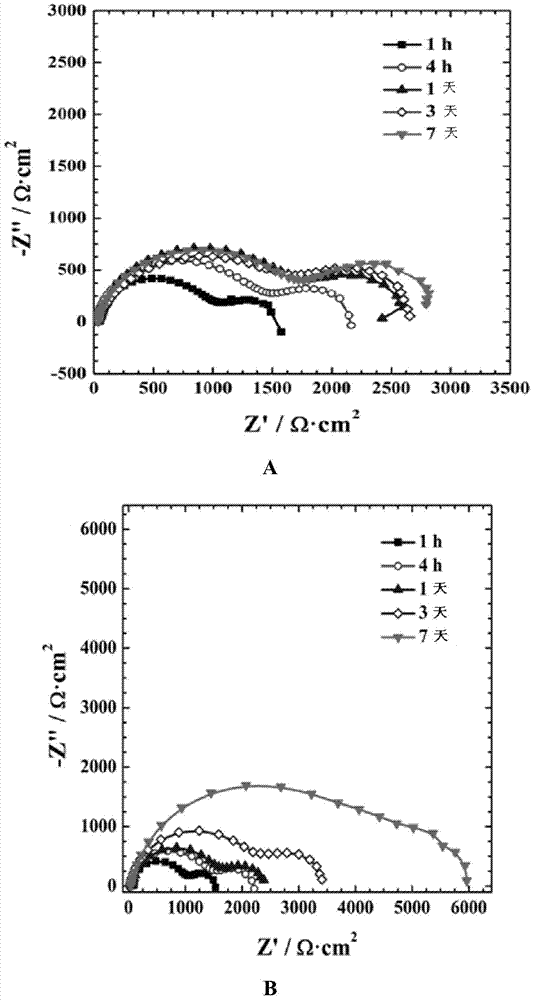

[0044] After the above coating treatment, the corrosion degradation rate of the magnesium-calcium alloy measured by electrochemical impedance spectroscopy was reduced by about 1 / 4 of that before the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com