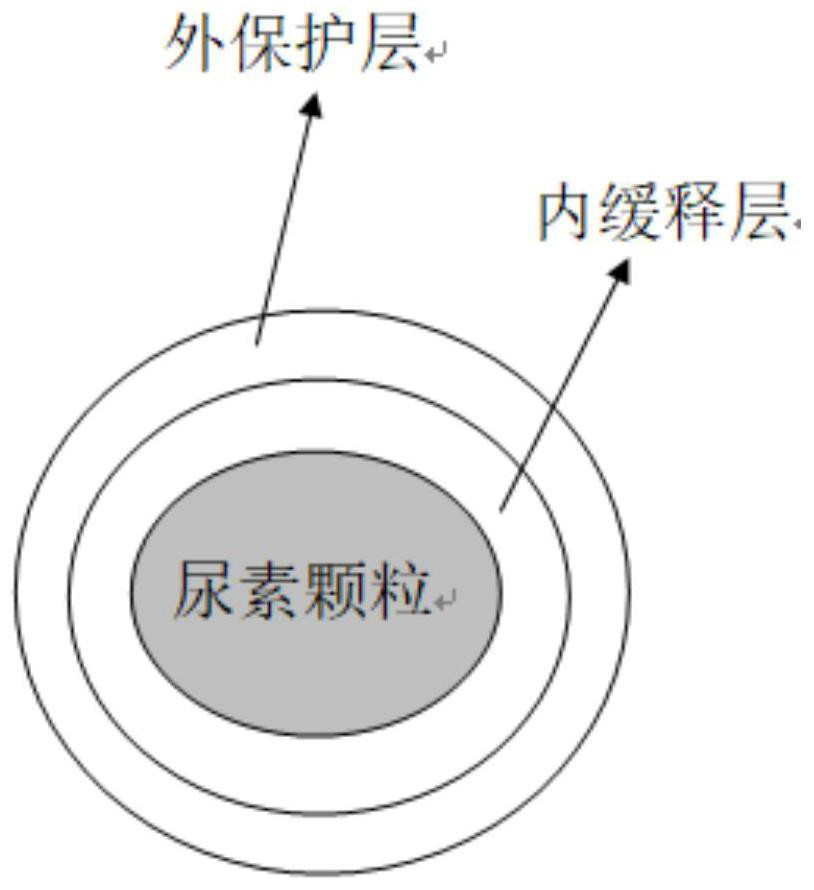

Environment-friendly slow-release coated urea fertilizer and preparation method thereof

A slow-release bag and environment-friendly technology, applied in layered/coated fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of insufficient film strength and poor water resistance, achieve good film formation and mechanical properties, and reduce soil bulk density , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

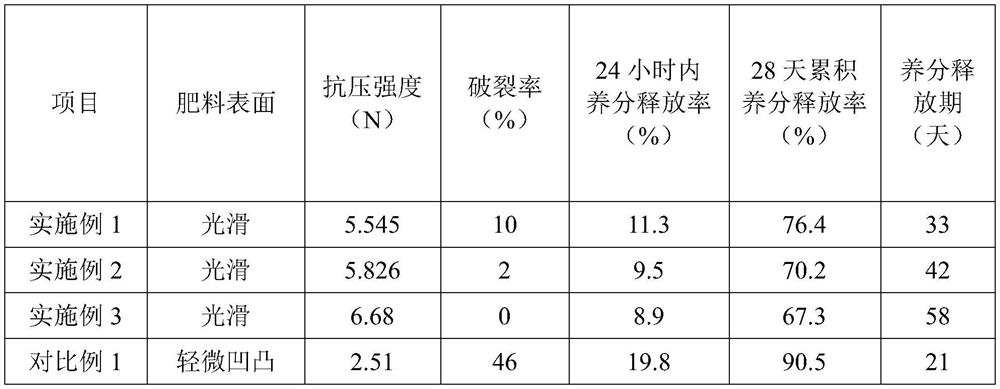

Embodiment 1

[0035] (1) Weigh polyvinyl alcohol 31.8g and deionized water 621.25g and add in the three-necked flask equipped with stirrer, condenser and thermometer, heat to 90°C, and dissolve solid polyvinyl alcohol under the stirring of electric stirrer , after the polyvinyl alcohol is completely dissolved, the temperature is lowered to 60 ° C, 3.2 g of polyvinyl pyrrolidone and 15.5 g of water-based acrylate emulsion are added, stirred at a constant temperature for 2 hours, and after complete mixing, the fly ash zeolite with a particle size of 5-10 μm is added. Powder 1.25g, stir at high speed for 1h, and configure into a water-based composite solution.

[0036] (2) put 700g of urea particles with a particle size of 2 to 4 mm into the fluidized bed, preheat for 10 to 20 min at a temperature of 50 to 60 ° C, and slowly feed the (1) gained water-based composite solution through a peristaltic pump. The injection is atomized by the high-pressure gas provided by the air compressor, and the coa...

Embodiment 2

[0039] (1) Weigh polyvinyl alcohol 38.2g and deionized water 606.25g and add in the three-necked flask equipped with stirrer, condenser and thermometer, heat to 90°C, and dissolve solid polyvinyl alcohol under the stirring of electric stirrer , after the polyvinyl alcohol is completely dissolved, the temperature is lowered to 60 ° C, 3.8 g of polyvinyl pyrrolidone and 18.5 g of water-based acrylate emulsion are added, stirred at a constant temperature for 2 hours, and after complete mixing, the fly ash zeolite with a particle size of 5 to 10 μm is added. Powder 1.5g, stir at high speed for 1h, and configure into a water-based composite solution.

[0040] (2) put 700g of urea particles with a particle size of 2 to 4 mm into the fluidized bed, preheat for 10 to 20 min at a temperature of 50 to 60 ° C, and slowly feed the (1) gained water-based composite solution through a peristaltic pump. The injection is atomized by the high-pressure gas provided by the air compressor, and the...

Embodiment 3

[0043] (1) Weigh polyvinyl alcohol 44.5g and deionized water 589.25g and add in the three-necked flask equipped with stirrer, condenser and thermometer, heat to 90°C, and dissolve solid polyvinyl alcohol under the stirring of electric stirrer , after the polyvinyl alcohol is completely dissolved, the temperature is lowered to 60 ° C, 4.5 g of polyvinyl pyrrolidone and 22 g of water-based acrylate emulsion are added, stirred at a constant temperature for 2 hours, and after complete mixing, the fly ash zeolite powder with a particle size of 5 to 10 μm is added. 1.75g, stirred at high speed for 1h, and configured into a water-based composite solution.

[0044] (2) put 700g of urea particles with a particle size of 2 to 4 mm into the fluidized bed, preheat for 10 to 20 min at a temperature of 50 to 60 ° C, and slowly feed the (1) gained water-based composite solution through a peristaltic pump. The injection is atomized by the high-pressure gas provided by the air compressor, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com