Surface-modified porcelain insulator and preparation method thereof

A porcelain insulator and surface modification technology, which is applied in the field of electric porcelain, can solve the problems of expensive organic polymer materials, poor anti-aging ability, and short service life, and achieve the effects of reducing pollution flashover, low cost, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

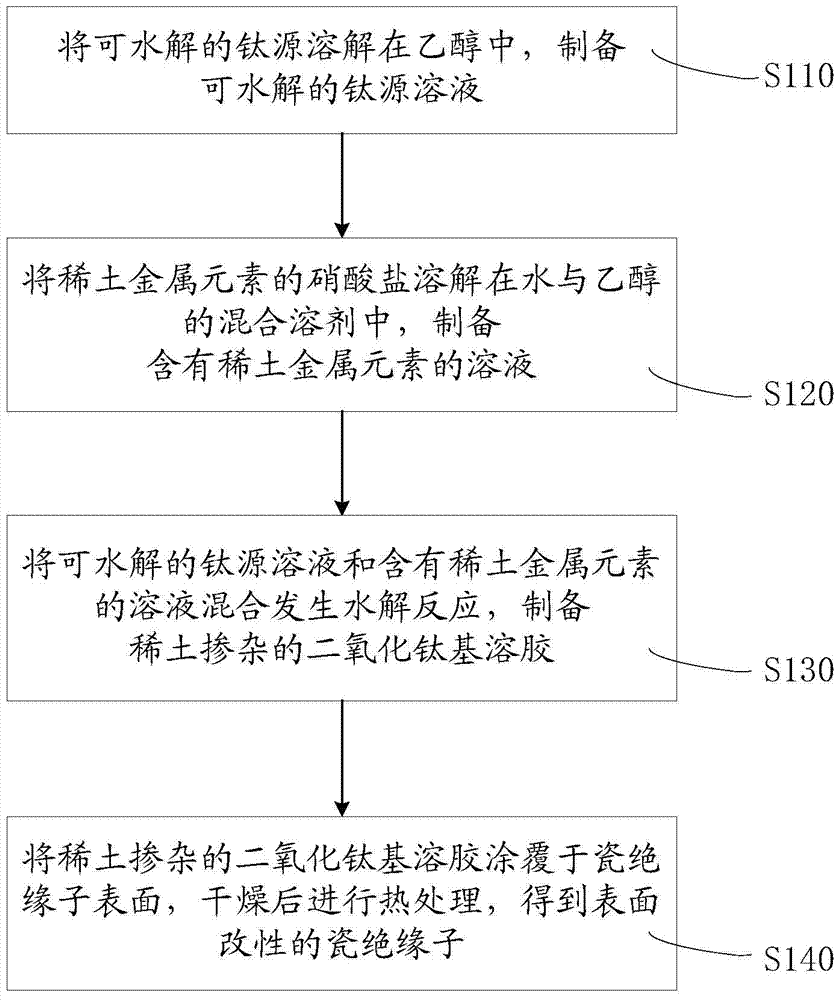

[0021] refer to figure 1 , a method for preparing a surface-modified porcelain insulator in one embodiment, comprising:

[0022] Step S110: dissolving the hydrolyzable titanium source in ethanol to prepare a hydrolyzable titanium source solution.

[0023] Wherein, in this embodiment, the hydrolyzable titanium source may be at least one of butyl titanate, tetraisopropyl titanate and titanium tetrachloride. Preferably, the hydrolyzed titanium source can be butyl titanate.

[0024] Preferably, in the hydrolyzable titanium source solution, the volume ratio of the molar amount of titanium element to ethanol is 0.5˜1.5 mol:1L.

[0025] Step S120: dissolving the nitrate of the rare earth metal element in a mixed solvent of water and ethanol to prepare a solution containing the rare earth metal element.

[0026] In one embodiment, in the solution containing the rare earth metal element, the concentration of the nitrate of the rare earth metal element is 0.05˜0.5 mol / L.

[0027] In...

Embodiment 1

[0045]Add butyl titanate to ethanol at a ratio of 0.5 mol:1 L of titanium element and ethanol, and mix and stir for 30 minutes to prepare a hydrolyzable titanium source solution.

[0046] Mix water and ethanol at a ratio of 1:1 by volume, slowly add 0.5mol / L yttrium nitrate solution according to the molar ratio of titanium element and rare earth metal element in the hydrolyzable titanium source to 100:0.1, adjust with nitric acid Its pH is 4.5, and a solution containing rare earth metal elements is prepared.

[0047] Slowly mix the hydrolyzable titanium source solution and the solution containing rare earth metal elements uniformly under the condition of stirring to form a titanium dioxide-based sol doped with rare earth yttrium.

[0048] The titanium dioxide-based sol doped with rare earth yttrium is coated on the surface of a model C4-80 porcelain insulator by brushing to form a film. Dry at 50°C for 30min, and then heat-treat at 450°C for 4h to obtain a surface-modified po...

Embodiment 2

[0050] Tetraisopropyl titanate was added to ethanol at a ratio of 1.5 mol:1 L of titanium element and ethanol, and mixed and stirred for 60 minutes to prepare a hydrolyzable titanium source solution.

[0051] Mix water and ethanol at a ratio of 1:3 by volume, slowly add 0.05mol / L yttrium nitrate solution according to the molar ratio of titanium element and rare earth metal element in the hydrolyzable titanium source to 100:5, adjust with nitric acid Its pH was adjusted to 5.0, and a solution containing rare earth metal elements was prepared.

[0052] Slowly mix the hydrolyzable titanium source solution and the solution containing rare earth metal elements uniformly under the condition of stirring to form a titanium dioxide-based sol doped with rare earth yttrium.

[0053] The titanium dioxide-based sol doped with rare earth yttrium is coated on the surface of a model C4-80 porcelain insulator by brushing to form a film. Dry at 80°C for 5min, and then heat-treat at 350°C for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com