Composition for optical material

A technology of optical materials and compositions, applied in optics, optical components, organic chemistry, etc., can solve the problems of low yield, the improvement of rib and rib can not be said to be sufficient, etc., and achieve excellent balance of physical properties and increase productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Hereinafter, the present invention will be more specifically described by way of synthesis examples, examples, and comparative examples, but the present invention is not limited to these examples. In addition, the evaluation of the obtained casting liquid (composition for optical materials) and resin (optical materials) was performed by the following method.

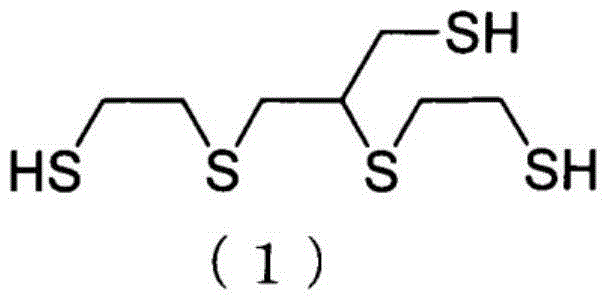

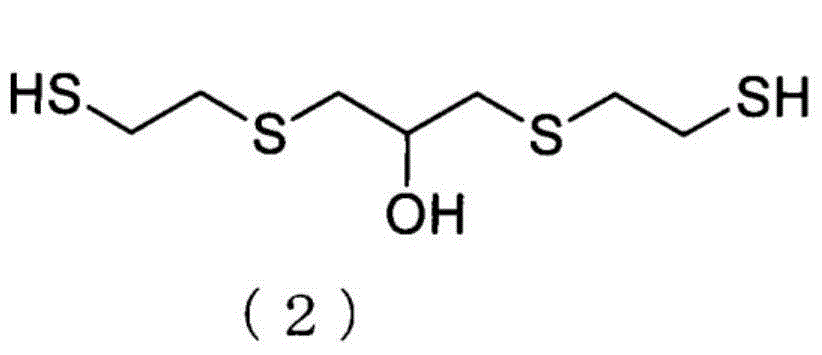

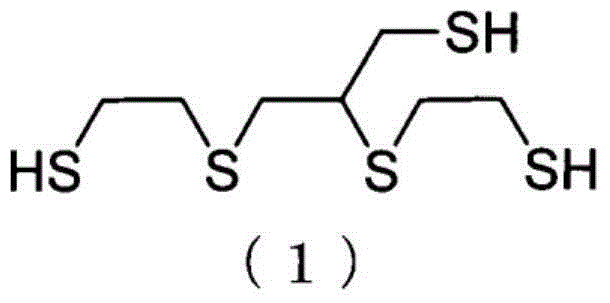

[0043] Quantification of compound (a) and compound (b) in polythiol

[0044] Quantification was performed by the absolute calibration curve method using a capillary gas chromatograph (manufactured by Shimadzu Corporation, GC2010, detector: hydrogen flame ionization detector (FID)) equipped with DB-5MS (Agilent Technologies).

[0045] · Viscosity of casting liquid

[0046] Viscosity at 20° C. was measured using a B-type viscometer (TOKISANGYO CO., LTD., TV10M type).

[0047] ・Streak generation rate of optical materials containing thiourethane resin

[0048] A mercury lamp light source was transmitted through 100...

Synthetic example 1

[0054] 76.0 parts by mass of water and 90.0 parts by mass (1.08 mol) of a 48% by mass sodium hydroxide aqueous solution were charged into a 2L four-necked reaction flask equipped with a stirrer, a reflux condenser, a nitrogen blowpipe, and a thermometer. After adding 169 parts by mass (2.16 mol) of 2-mercaptoethanol dropwise over 30 minutes at 30°C, 99.9 parts by mass (1.08 mol) of epichlorohydrin was added dropwise over 3 hours at the same temperature to perform 1 hour to ripen. Next, 450.1 parts by mass (4.32 mol) of 36 mass % hydrochloric acid water and 304.5 parts by mass (4.00 mol) of thiourea were added, and it refluxed at 110 degreeC for 8 hours, and thiouronium saltization was performed. After condensing to 50° C., 450.0 parts by mass of toluene and 298 parts by mass (5.21 mol) of 28 mass % ammonia solution were added for hydrolysis to obtain a toluene solution of polythiol as the main component of compound (a). The toluene solution was acid-washed and washed with wat...

Synthetic example 2

[0056] 76.0 parts by mass of water and 90.0 parts by mass (1.08 mol) of a 48% by mass sodium hydroxide aqueous solution were charged into a 2L four-necked reaction flask equipped with a stirrer, a reflux condenser, a nitrogen blowpipe, and a thermometer. After adding 169 parts by mass (2.16 mol) of 2-mercaptoethanol dropwise over 10 minutes at 5°C, 99.9 parts by mass (1.08 mol) of epichlorohydrin was added dropwise over 1 hour at the same temperature, The temperature was raised to 30°C. Next, 450.1 parts by mass (4.32 mol) of 36 mass % hydrochloric acid water and 206 parts by mass (2.70 mol) of thiourea were added, and it refluxed at 110 degreeC for 30 minutes, and thiouronium saltization was performed. After cooling to 30°C, 450.0 parts by mass of toluene and 300 parts by mass (5.25 mol) of 28% by mass ammonia solution were added, and hydrolyzed at 50°C to obtain a toluene solution of polythiol as the main component of compound (b). The toluene solution was acid-washed and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com