Magnetite hydrotalcite/cuprous oxide/titanium dioxide composite photocatalyst, as well as preparation method and application of composite photocatalyst

A technology of titanium dioxide and cuprous oxide, applied in the field of water treatment, can solve the problems of cathode corrosion, electron-hole recombination, etc., and achieve the effects of environmental friendliness, wide sources, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of magnetite hydrotalcite / cuprous oxide / titanium dioxide photocatalyst, its preparation method comprises the following steps:

[0035] Add 200mL0.5mol / L copper sulfate solution (16g) into the Erlenmeyer flask, add 5g magnetite and 5g hydrotalcite, stir for 30min, slowly add 100mL0.5mol / L ascorbic acid solution (8.8g) and stir evenly, then add Stir 10g of titanium dioxide for 30min, slowly add 400mL of 1.5mol / L sodium hydroxide solution (24g, 40°C) while stirring under ultrasonic conditions, ultrasonicate at 40°C for 30min, then centrifuge, wash with water (3 times), Wash with alcohol (3 times), and finally dry in a vacuum oven (40° C.), and grind the obtained product to obtain the magnetite hydrotalcite / cuprous oxide / titanium dioxide photocatalyst.

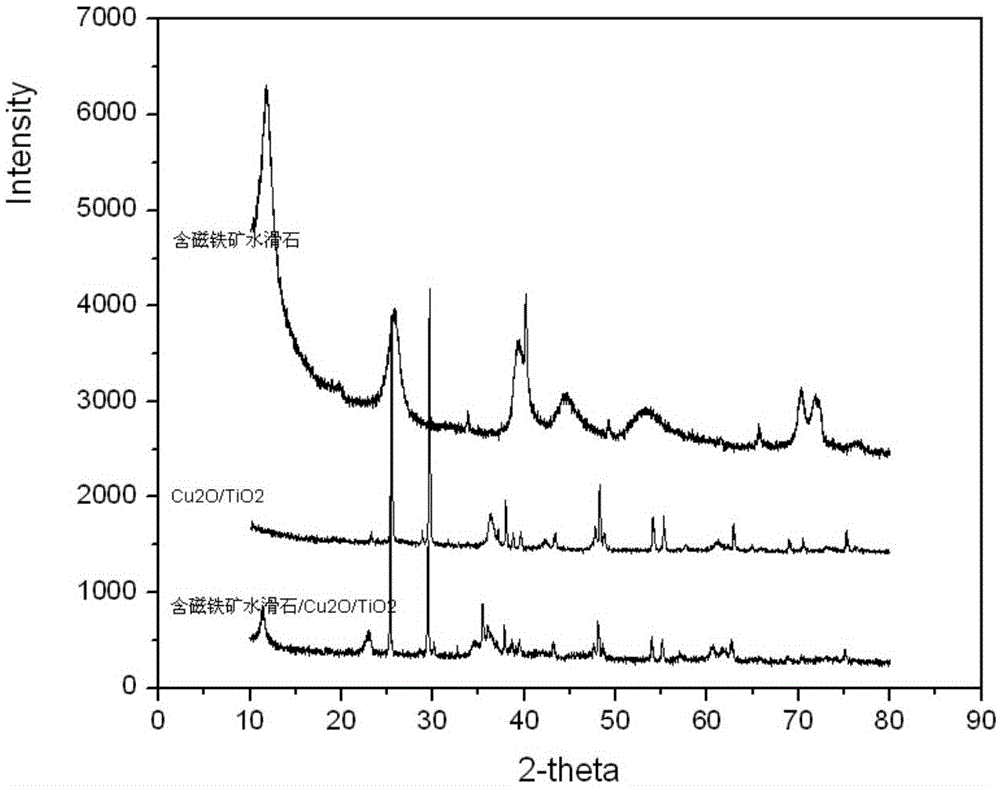

[0036] figure 1 It is the XRD pattern of the magnetite hydrotalcite / cuprous oxide / titania photocatalyst obtained in this embodiment. It can be seen from the analysis of the figure that the baseline of magnetite is ...

Embodiment 2

[0044] A kind of magnetite hydrotalcite / cuprous oxide / titanium dioxide photocatalyst, its preparation method comprises the following steps:

[0045] Add 15 mL of 0.35 mol / L copper sulfate solution (0.8 g) into the Erlenmeyer flask, add 0.2 g of magnetite and 0.2 g of hydrotalcite, stir for 20 min, slowly add 4 mL of 0.5 mol / L ascorbic acid solution (0.4 g) and stir well , then add 0.5g of titanium dioxide and stir for 20min, slowly add 80mL of 0.5mol / L sodium hydroxide solution (1.6g, 30°C) while stirring under ultrasonic conditions, ultrasonicate for 20min at 30°C, then centrifuge and wash with water (3 times), alcohol washing (3 times), and finally dried in a vacuum oven (45° C.), and the resulting product was ground to obtain the magnetite hydrotalcite / cuprous oxide / titanium dioxide photocatalyst.

Embodiment 3

[0047] A kind of magnetite hydrotalcite / cuprous oxide / titanium dioxide photocatalyst, its preparation method comprises the following steps:

[0048] Add 100mL of 0.4mol / L copper sulfate solution (6.4g) into the Erlenmeyer flask, add 1.6g of magnetite and 1.6g of hydrotalcite, stir for 25min, slowly add 8mL of 4.5mol / L ascorbic acid solution (6.3g) and stir evenly , then add 3.6g of titanium dioxide and stir for 25min, slowly add 400mL of 0.8mol / L sodium hydroxide solution (12.8g, 35°C) while stirring under ultrasonic conditions, ultrasonicate for 25min at 35°C, then centrifuge and wash with water (3 times), alcohol washing (3 times), and finally dried in a vacuum oven (50° C.), and the resulting product is ground to obtain the magnetite hydrotalcite / cuprous oxide / titanium dioxide photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com