Quick purifying agent for nonselective heavy metal wastewater

A non-selective, heavy metal technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of greater influence on the pH value of the water body, the cost of secondary pollution of the water body, and the difficulty of removal and other problems, to achieve the effect of low requirements for equipment conditions, solving universal problems, and good processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

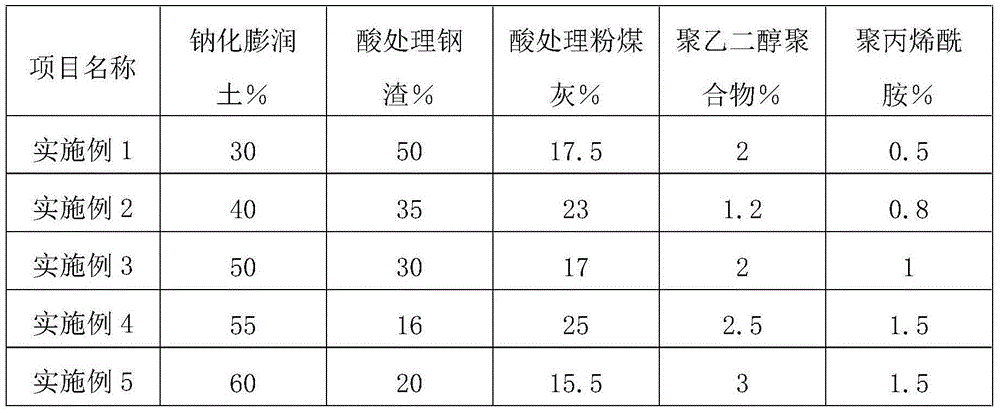

Embodiment 1

[0027] First, soak the steel slag and fly ash in hydrochloric acid with a concentration of 15% for 4 hours, respectively, and use a ball mill to grind them to no less than 200 mesh for later use; then sodium-treat the bentonite until the CEC value is ≧180mg / g, and dry them Wait until the water content is ≦1%; then select ethylene glycol polymers and polyacrylamides with fixed molecular weights, and finally add each component to a closed three-shaft mixer according to the weight percentage of each component in Table 1. After stirring for 15-20 minutes, film Once packaged, you can.

[0028] Get Wuhan Iron and Steel Cold Rolling Plant chromium-containing passivation liquid waste 1000ml, place in conical flask, wherein chromium element concentration is 75mg / L, take by weighing component 1 purifying agent according to 1% weight ratio (being 10g), add conical In the bottle, the Erlenmeyer flask was placed on an automatic rotary mixer to vibrate and stir for 2 minutes, then filtered,...

Embodiment 2

[0030] Its specific preparation method is the same as that of Example 1, except that the materials are taken according to the weight percentage of each component in Table 1.

[0031] Take 1000ml of heavy metal waste liquid from Huanggang Wuxing Metal Products Factory and place it in a conical flask, which contains Pb 2+ , Zn 2+ , Mn 2+ and PO 4 2- , the environmental protection department detects that the concentration of the above-mentioned several harmful elements exceeds the standard, weighs the component 2 purifier according to 1% by weight (i.e. 10g), adds it to the conical flask, and places the conical flask on an automatic rotary mixer to oscillate and stir for 2 Minutes, after filtration, determination of Pb in the filtrate 2+ , Zn 2+ , Mn 2+ and PO 4 2- The concentration is lower than the national environmental protection emission threshold, and the removal effect has been achieved.

Embodiment 3

[0033] Its specific preparation method is the same as that of Example 1, except that the materials are taken according to the weight percentage of each component in Table 1.

[0034] Take 1000ml of waste liquid from Jingzhou Sanonda Pesticide Factory and put it in a conical flask, which contains Pb 2+ 、Cd 2+ , Mn 2+ and PO 4 2- , the environmental protection department detects that the concentration of the above-mentioned several harmful elements exceeds the standard, weighs the component 3 purifying agent according to 1% by weight (i.e. 10g), adds it to the conical flask, and places the conical flask on an automatic rotary mixer to oscillate and stir for 2 Minutes, after filtration, determination of Pb in the filtrate 2+ 、Cd 2+ , Mn 2+ and PO 4 2-The concentration is lower than the national environmental protection emission threshold, and the removal effect has been achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com