A method and device capable of significantly improving the hydrogen embrittlement resistance of stainless steel materials

A kind of stainless steel, remarkable technology, applied in the field of anti-hydrogen embrittlement performance of stainless steel material (316L), can solve the problems of introducing a large number of hydrogen atoms, complicated process, large investment, etc., to achieve outstanding anti-hydrogen embrittlement effect, reduce pollution, and improve anti-hydrogen embrittlement performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

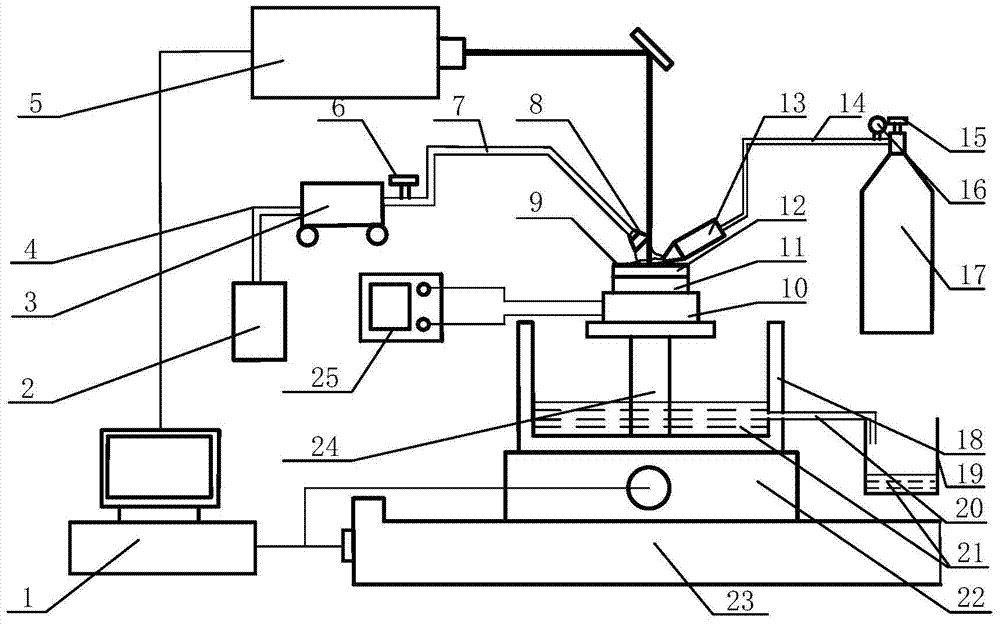

[0042] Such as Figure 1~3 shown.

[0043] Taking 316L stainless steel as an example below, use a method in the present invention that can significantly improve the hydrogen embrittlement resistance of 316L stainless steel to carry out surface treatment, the principle is as follows figure 1 As shown, the laser energy of laser 5 is set to 8J, the beam diameter is 4 mm, and the spot overlap rate is 50%. During specific implementation, the laser energy, beam diameter, and spot overlap rate can be adjusted and selected according to the size, thickness and model of the workpiece; the specific steps include:

[0044] A. Place the stainless steel workpiece 11 on the heating platform 10, open the rotary valve 15 of the nitrogen tank 17, and adjust the outlet pressure of the nozzle 13 to 3.5×10 according to the pressure gauge 16 5 Pa, to drive away the hydrogen atoms overflowing from the surface of the sample or in the air; at the same time, turn on the heating platform controller 25, ...

Embodiment 2

[0052] Such as figure 1 shown.

[0053] A device that can significantly improve the hydrogen embrittlement resistance of 316L stainless steel, which includes a first horizontal motion platform 22 and a second horizontal motion platform 23, the first horizontal motion platform 22 is installed on the second horizontal motion platform 23, the first horizontal motion platform The platform 22 and the second horizontal motion platform 23 work together under the control of the computer 1 to move forward, backward, and left and right in the horizontal direction of the work, providing motion guarantee for the laser impact of the stainless steel workpiece 11. The first horizontal motion platform 22 is provided with a silicon oil recovery constraint. In the collection tank 18 of layer 9, a boss 24 is installed at the center of the collection tank 18. The height of the boss 24 can be designed to be high or fixed. The boss 24 is used to place the heating platform 10, and the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com