Preparation method of Si-doped low-Sm-content Sm-Co amorphous matrix magnetic alloy

A magnetic alloy, sm-co technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of difficult to obtain amorphous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

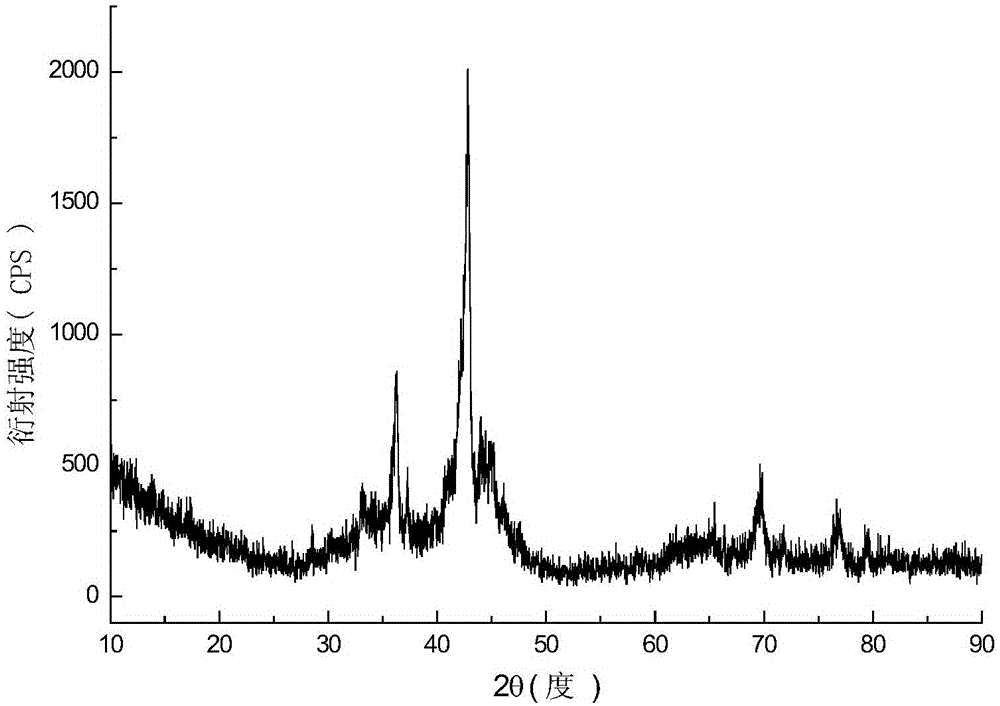

Embodiment 1

[0054] Si-doped low Sm content Sm-Co type amorphous base magnetic alloy (Sm 12 co 60 Fe 8 Zr 5 Nb 5 Al 6 B 4 ) 99.9 Si 0.1 preparation.

[0055] The first step, raw material preparation:

[0056] According to the ratio of raw materials (Sm 12 co 60 Fe 8 Zr 5 Nb 5 Al 6 B 4 ) 99.9 Si 0.1 The composition range of the elements defined by atomic percentage in the formula is used to weigh the raw materials involved in the formula: pure Sm, pure Co, pure Fe, pure Zr, pure Nb, pure Al, B-Fe alloy and pure Si The dosage, thus complete the preparation of raw materials;

[0057] The second step is to melt the raw materials to prepare master alloy ingots:

[0058] Put all the raw materials prepared in the first step into the crucible of vacuum arc melting furnace or vacuum induction melting furnace. -3 Pa, the furnace temperature rises to higher than 1600°C until all the raw materials are melted evenly, and then poured into the mold to cool, that is, (Sm 12 co 60 Fe ...

Embodiment 2

[0066] Si-doped low Sm content Sm-Co type amorphous base magnetic alloy (Sm 12 co 60 Fe 8 Zr 5 Nb 5 al 6 B 4 ) 97 Si 3 preparation.

[0067] The first step, raw material preparation:

[0068] According to the ratio of raw materials (Sm 12 co 60 Fe 8 Zr 5 Nb 5 al 6 B 4 ) 97 Si 3 The composition range of the elements defined by atomic percentage in the formula is used to weigh the raw materials involved in the formula: pure Sm, pure Co, pure Fe, pure Zr, pure Nb, pure Al, B-Fe alloy and pure Si The dosage, thus complete the preparation of raw materials;

[0069] The second step is to melt the raw materials to prepare master alloy ingots:

[0070] Put all the raw materials prepared in the first step into the crucible of vacuum arc melting furnace or vacuum induction melting furnace. -3 Pa, the furnace temperature rises to higher than 1600°C until all the raw materials are melted evenly, and then poured into the mold to cool, that is, (Sm 12 co 60 Fe 8 Zr 5...

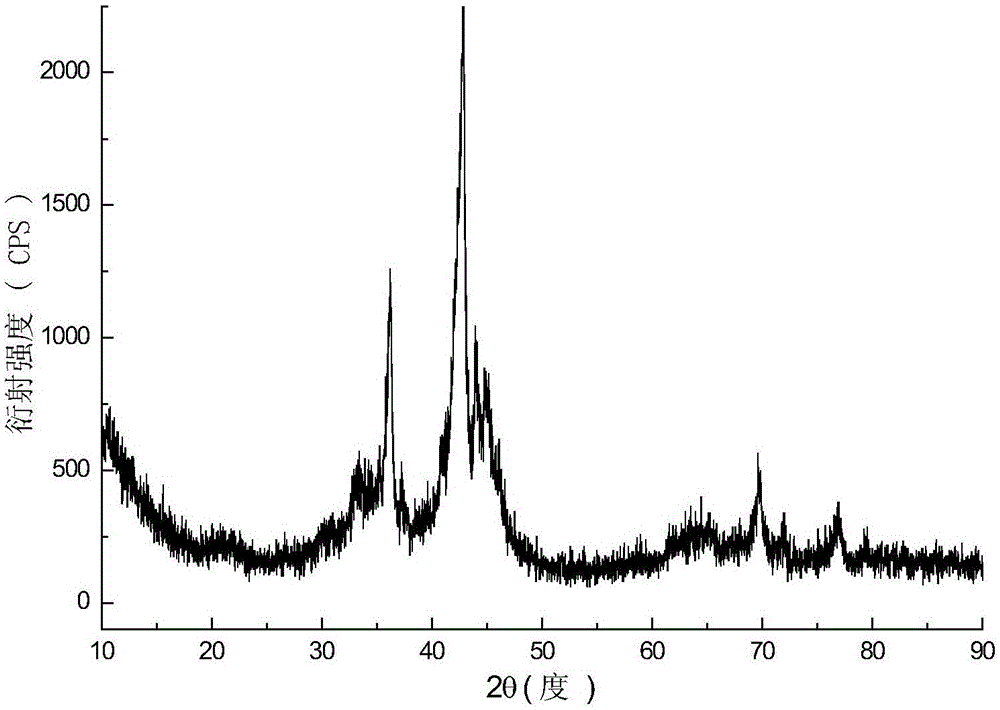

Embodiment 3

[0078] Si-doped low Sm content Sm-Co type amorphous base magnetic alloy (Sm 12 co 60 Fe 8 Zr 5 Nb 5 al 6 B 4 ) 94 Si 6 preparation.

[0079] The first step, raw material preparation:

[0080] According to the ratio of raw materials (Sm 12 co 60 Fe 8 Zr 5 Nb 5 al 6 B 4 ) 94 Si 6 The composition range of the elements defined by atomic percentage in the formula is used to weigh the raw materials involved in the formula: pure Sm, pure Co, pure Fe, pure Zr, pure Nb, pure Al, B-Fe alloy and pure Si The dosage, thus complete the preparation of raw materials;

[0081] The second step is to melt the raw materials to prepare master alloy ingots:

[0082] Put all the raw materials prepared in the first step into the crucible of vacuum arc melting furnace or vacuum induction melting furnace. -3 Pa, the furnace temperature rises to higher than 1600°C until all the raw materials are melted evenly, and then poured into the mold to cool, that is, (Sm 12 co 60 Fe 8 Zr 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com