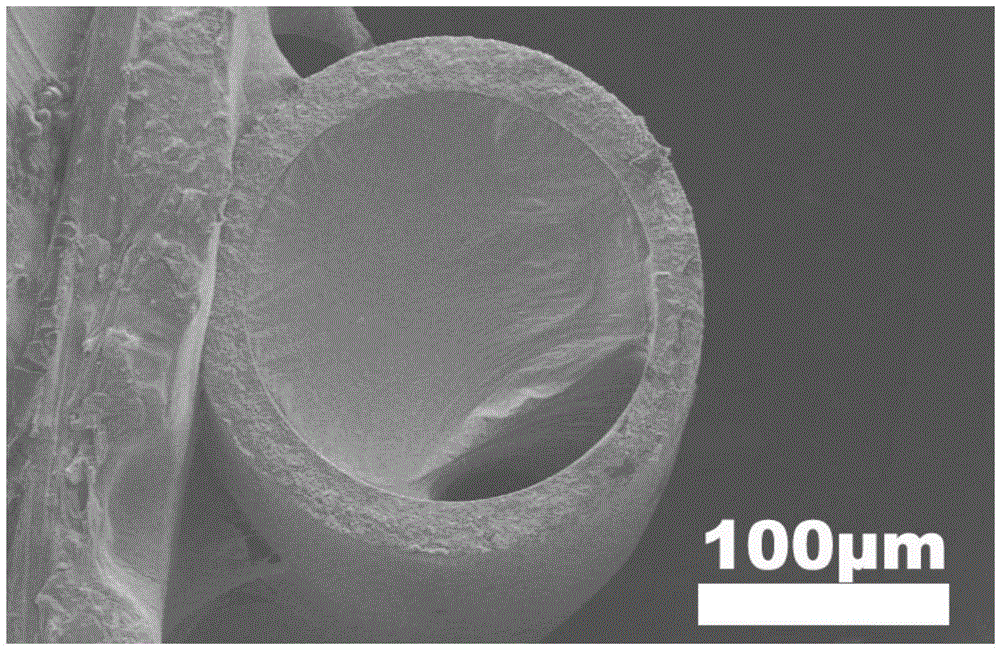

Heat-storing and temperature-regulating fiber and preparation method thereof

A technology of heat storage, temperature adjustment and fiber, which is applied in fiber treatment, fiber chemical characteristics, wet spinning method, etc., can solve the problems of limiting heat transfer efficiency, etc., and achieve the effect of improving mechanical properties, good functionality, and good coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

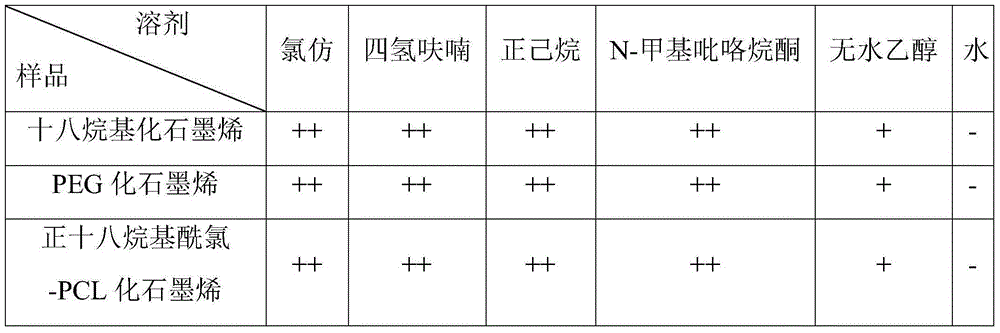

Embodiment 1

[0036] The phase change material is a poly(styrene-co-maleic anhydride)-g-n-octadecyl alcohol / octadecyl graphene composite phase change material; the phase change material is obtained through the following method: first Octaalkylated graphene is uniformly dispersed in chloroform to obtain A, and the massfraction of octadecylated graphene in chloroform is 1wt%; Simultaneously, the number of side chain carbon atoms is eighteen poly(styrene-co- Maleic anhydride)-g-n-octadecanol is dissolved in tetrahydrofuran, and the massfraction of poly(styrene-co-maleic anhydride)-g-n-octadecanol in tetrahydrofuran is 10wt%, obtains B; Secondly, the A and B are mixed, and the solvent is evaporated to obtain the phase change material, wherein the mass fraction of octadecylated graphene in the phase change material is 0.5 wt%. The fiber-forming polymer is an acrylonitrile-vinylidene chloride (molar ratio is 85 / 15) copolymer (Mn=32,000);

[0037] Both the phase change material and the fiber-form...

Embodiment 2

[0041] The phase change material is a poly(styrene-co-maleic anhydride)-g-n-octadecyl alcohol / octadecyl graphene composite phase change material; the phase change material is obtained through the following method: first Octaalkylated graphene is uniformly dispersed in chloroform to obtain A, and the massfraction of octadecylated graphene in chloroform is 1wt%; Simultaneously, the number of side chain carbon atoms is eighteen poly(styrene-co- Maleic anhydride)-g-n-octadecanol is dissolved in tetrahydrofuran, and the massfraction of poly(styrene-co-maleic anhydride)-g-n-octadecanol in tetrahydrofuran is 10wt%, obtains B; Secondly, the A and B are mixed, and the solvent is evaporated to obtain the phase change material, wherein the mass fraction of octadecylated graphene in the phase change material is 2 wt%. The fiber-forming polymer is an acrylonitrile-vinylidene chloride (molar ratio is 85 / 15) copolymer (Mn=32,000);

[0042] Both the phase change material and the fiber-formin...

Embodiment 3

[0046] The phase change material is a poly(styrene-co-maleic anhydride)-g-n-octadecyl alcohol / octadecyl graphene composite phase change material; the phase change material is obtained through the following method: first Octaalkylated graphene is uniformly dispersed in chloroform to obtain A, and the massfraction of octadecylated graphene in chloroform is 1wt%; Simultaneously, the poly(styrene-co- Maleic anhydride)-g-n-octadecanol is dissolved in tetrahydrofuran, and the massfraction of poly(styrene-co-maleic anhydride)-g-n-octadecanol in tetrahydrofuran is 10wt%, obtains B; Secondly, the A and B are mixed, and the solvent is evaporated to obtain the phase change material, wherein the mass fraction of octadecylated graphene in the phase change material is 4wt%. The fiber-forming polymer is an acrylonitrile-vinylidene chloride (molar ratio is 85 / 15) copolymer (Mn=32,000);

[0047] Both the phase change material and the fiber-forming polymer are dried until the moisture content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| exothermic temperature | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com