Phase change heat storage device

A phase-change heat storage and heat exchange device technology, applied in heat storage equipment, heat exchange equipment, heat exchanger types, etc., can solve the problems of poor temperature uniformity of heat accumulators, increased mixing and redistribution, and limited heat storage efficiency. , to achieve the effect of isotropic specific strength, high specific strength and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

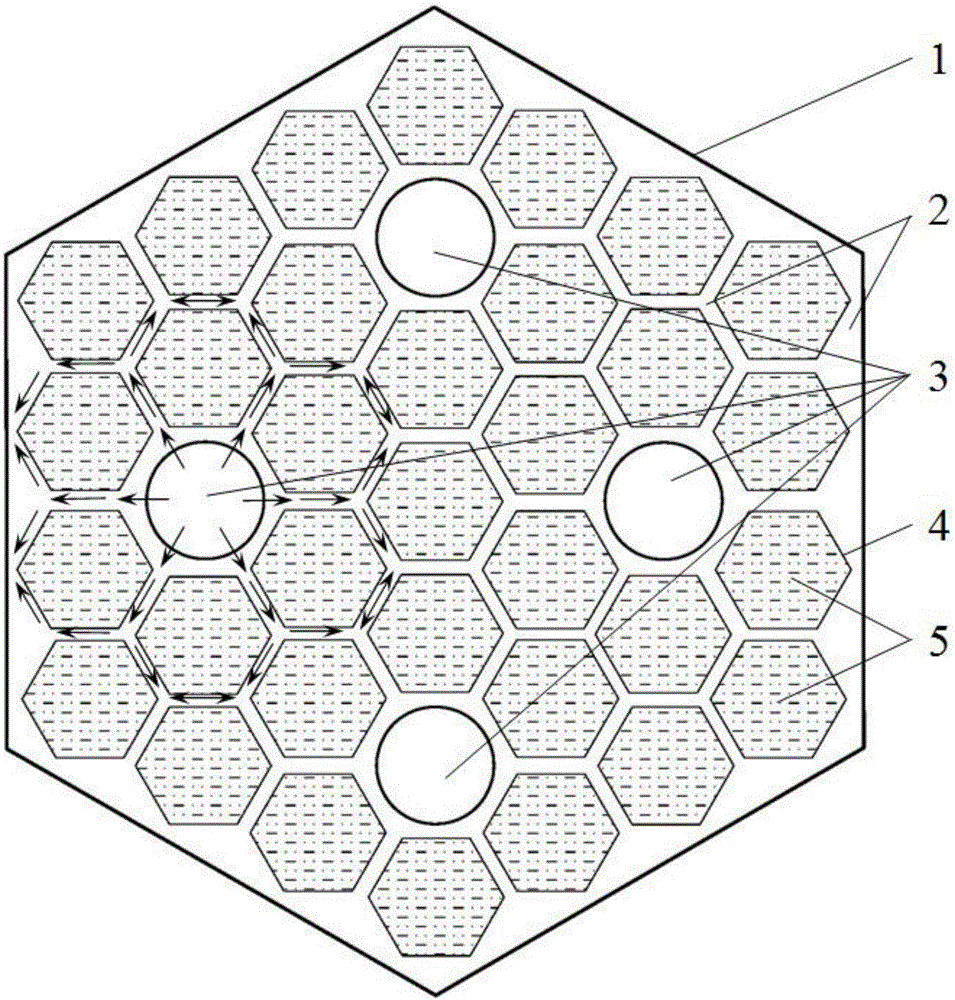

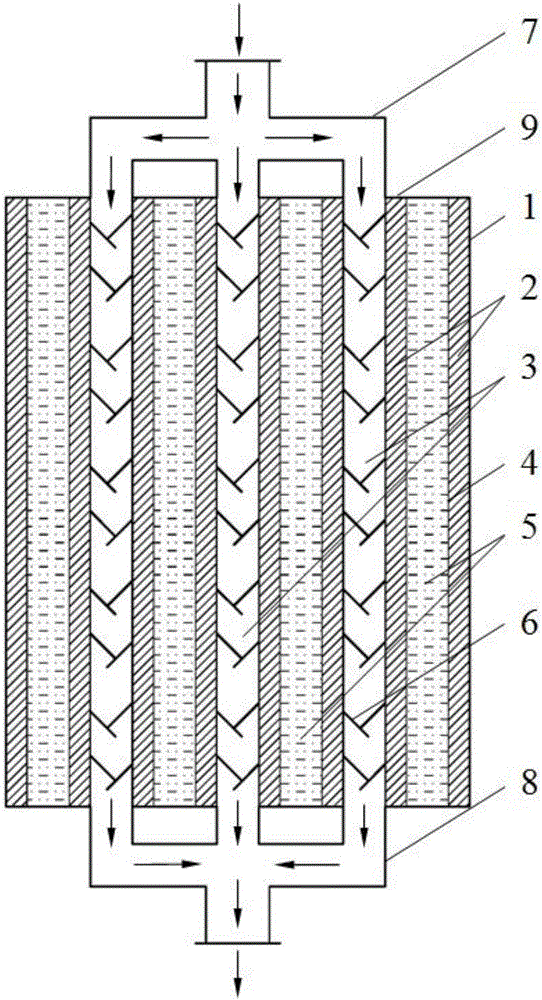

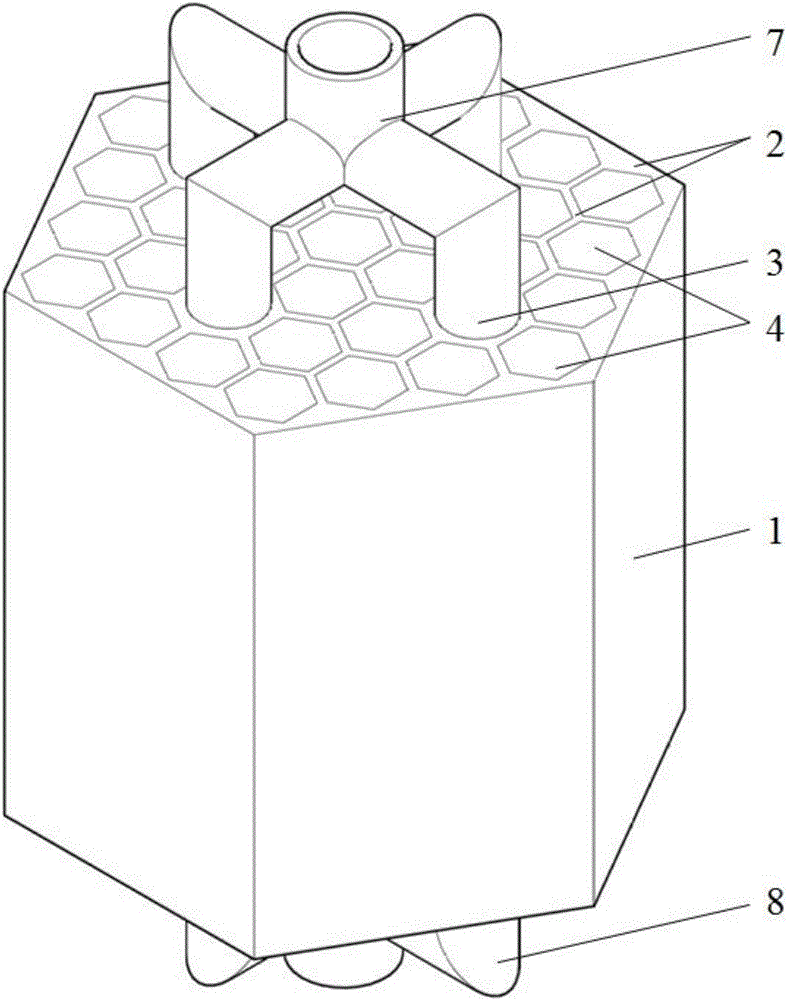

[0034] figure 2 , image 3 A schematic diagram of the overall structure of the heat accumulator is given, a solid-liquid phase change heat accumulator, which consists of a heat exchanger shell 1, a metal skeleton 2, a heat exchange pipe 3, a phase change material filling channel 4, and a phase change heat accumulator. The thermal material 5, the chaotic spoiler 6, the flow diversion device 7, the current collection device 8 and the thermal insulation material 9 are composed. figure 1 A schematic diagram of the arrangement structure of the metal skeleton channels and heat exchange pipes of the regenerator is given. The metal skeleton 2 is a hexagonal prism structure with multiple channels. The channels 4 are arranged in parallel according to the imitation honeycomb structure. The hexagonal channels evenly pave the entire heat storage section, effectively ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com