Refrigeration-assisted adsorption type vocs recovery device and recovery method

A recovery device and adsorption device technology, applied in the field of refrigeration-assisted adsorption type VOCs recovery device, can solve the problems of short service life of adsorbent materials, low refrigeration performance coefficient, poor adsorption effect, etc. The effect of cycle change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

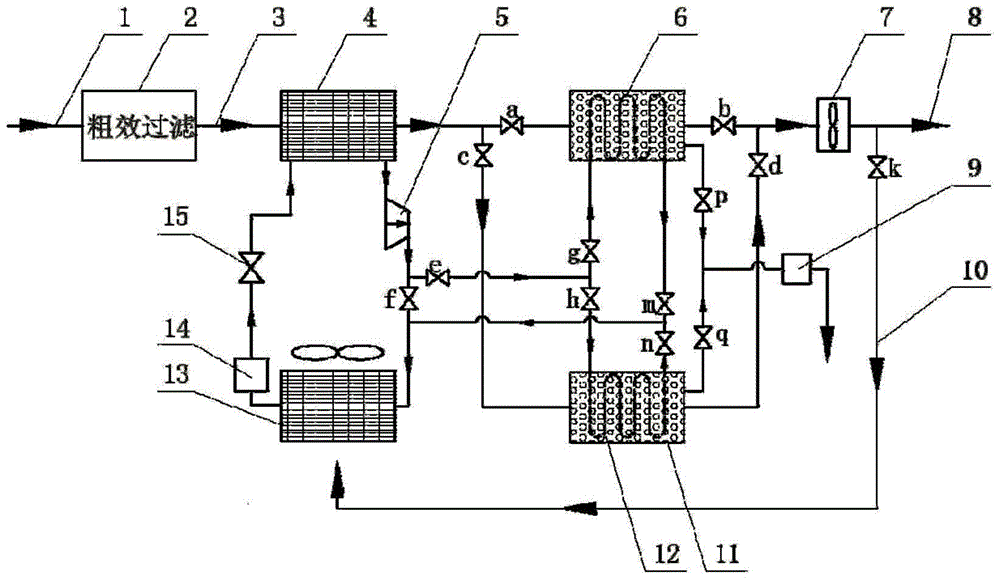

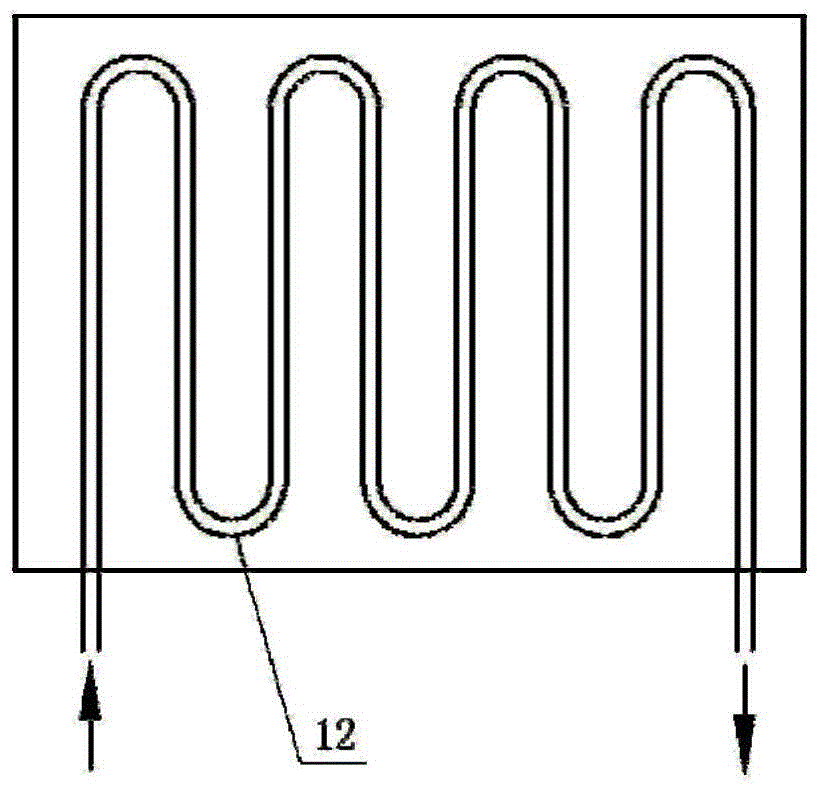

[0034] refer to figure 1 , Refrigeration-assisted adsorption VOCs recovery device, including sequentially connected exhaust inlet 1, coarse filter 2, cooling unit, adsorption device, fan 7, branch diversion channel 10, vacuum pump 9 for desorption process, and related pipeline stop valves, etc. , characterized in that: the cooling unit includes a condenser 4, a compressor 5, an air-cooled condenser 13, a liquid storage tank 14, a throttle valve 15, and the like. The adsorption device includes two adsorption beds connected in parallel, a first adsorption bed 6 and a second adsorption bed 11, and a heating plate 12 is provided on the adsorption bed. The outlet of the condenser 4 is connected to the inlet of the compressor 5, and the outlet of the compressor 5 is connected to the inlet of the heating coil 12 and the inlet of the air-cooled condenser 13 respectively through stop valves e, f, g, h, and the outlet of the heating coil 12 is passed through The stop valves m and n are...

Embodiment 2

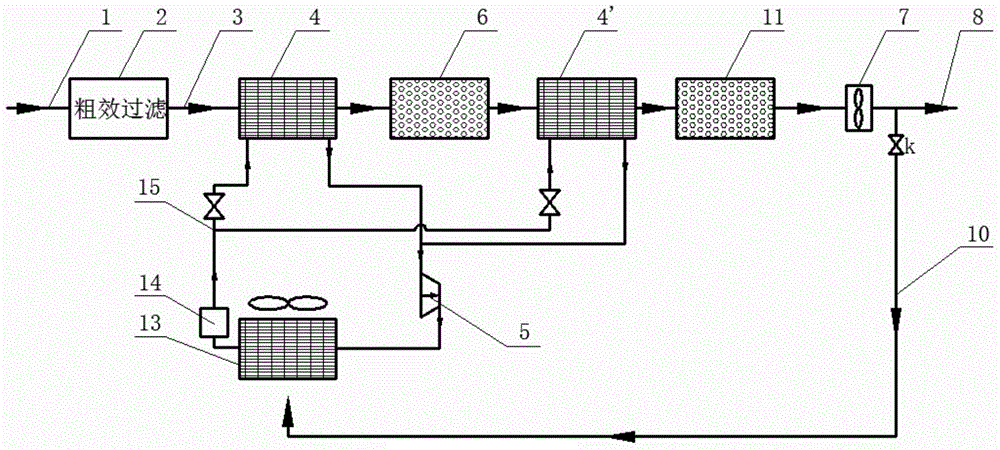

[0045] A refrigeration-assisted condensing VOCs recovery device, see image 3 , comprising a coarse-effect filter unit 2, a first condenser 4, a first adsorption bed 6, a second condenser 4', a second adsorption bed 11, and a fan 7 connected in sequence, and the fan 7 is respectively connected to the branch diversion channel through a shut-off valve 10 is connected to the exhaust port 8, the outlet of the branch diversion channel 10 directly leads to the air-cooled condenser 13, the refrigerant outlets of the first condenser 4 and the second condenser 4' are respectively connected with the inlet of the compressor 5, and the outlets of the compressor 5 The outlet is connected to the air-cooled condenser 13 and the inlet of the liquid storage tank 14 in turn, and the outlet of the liquid storage tank 14 is respectively connected to the refrigerant inlets of the first condenser 4 and the second condenser 4' through a stop valve.

[0046] Using the refrigeration-assisted adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com