Three-dimensional fused deposition polyamide forward-osmosis membrane as well as preparation method and application thereof

A forward osmosis membrane and forward osmosis technology, applied in the field of materials, can solve the problems that the forward osmosis membrane needs to be improved, achieve a good degree of hydrophilicity, improve performance, and increase the effect of retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1 prepares forward osmosis membrane

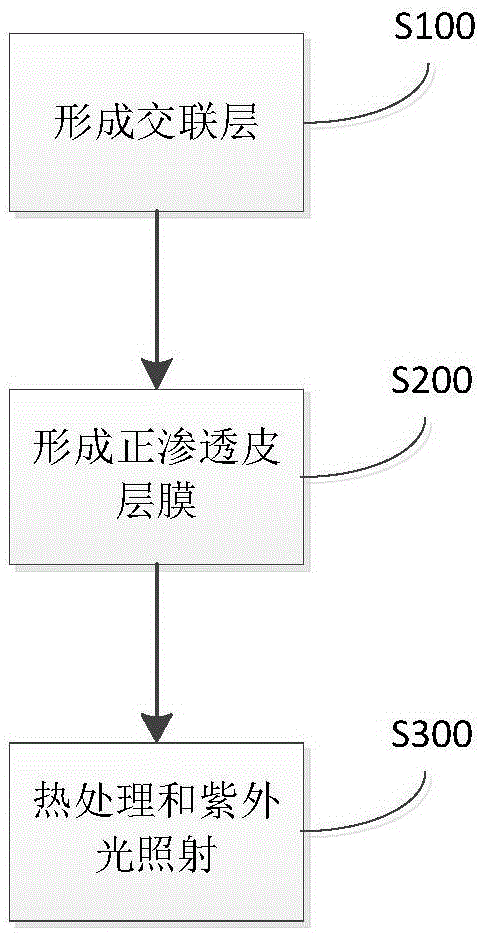

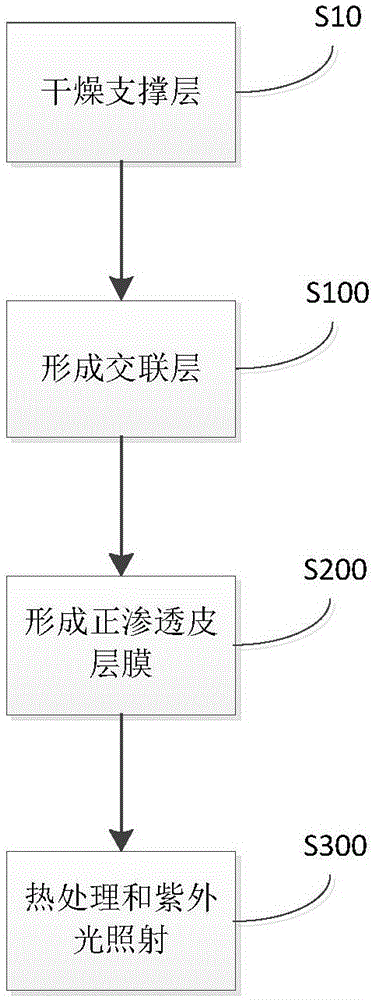

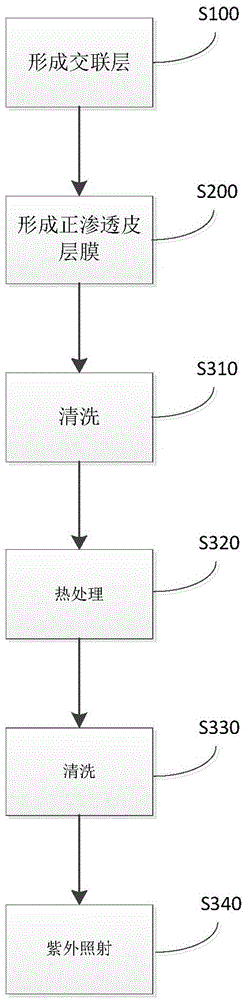

[0060] In this example, refer to Figure 8 , to prepare a forward osmosis membrane, wherein the specific steps and conditions are as follows:

[0061] Using a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 80kDa as the base membrane, the surface of the membrane was first washed with deionized water and dried in a 90°C drying oven for 2 hours. Then immediately immersed in n-hexane solution containing 0.5% by weight of trimesoyl chloride (TMC), the immersion time was 20 seconds. Then the membrane was taken out and placed in the air, and dried at room temperature for 1 minute to completely volatilize the n-hexane solvent on the surface of the membrane. Then put the TMC-attached base film into the 3D printer, deposit and print the mixed material of polyamide and photocrosslinking agent on the upper surface of the base film according to the pre-set program, take out the sample after cooling, and...

Embodiment 2

[0076] With the NaCl aqueous solution of concentration 2mol / L as draw liquid, take twice distilled water as raw material liquid, test the forward osmosis membrane prepared in embodiment 1, test according to the method described in embodiment 1 and according to the formula in embodiment 1 Calculate the water flux and rejection of the forward osmosis membrane. First place the forward osmosis membrane (FO membrane) prepared according to the embodiment of the present invention in the system, at room temperature (23°C), by turning on the peristaltic pump and adjusting the valve, control the draw liquid and raw material liquid to have a certain flow rate, so that The water flow pressure is maintained at 0.1MPa, and the pressure in the system is monitored through a pressure gauge. The quality of the raw material solution consumed through the FO membrane was tested by an electronic balance. By calculation, the water permeation per unit area and unit time of the forward osmosis membra...

Embodiment 3

[0078] MgSO with a concentration of 2mol / L 4 The aqueous solution is the drawing liquid, and the double distilled water is used as the raw material liquid to test the forward osmosis membrane prepared in Example 1, test according to the method described in Example 1 and calculate the water flow rate of the forward osmosis membrane according to the formula in Example 1. volume and retention. Put the forward osmosis membrane (FO membrane) prepared according to the embodiment of the present invention in the system, at room temperature (23°C), by turning on the peristaltic pump and adjusting the valve, control the draw liquid and raw material liquid to have a certain flow rate, so that the water flow The pressure is maintained at 0.1MPa, and the pressure in the system is monitored through a pressure gauge. The quality of the raw material solution consumed through the FO membrane was tested by an electronic balance. By calculation, the water permeation per unit area and unit time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com