Macroporous spherical composite catalyst for removing benzene series in air and preparation method thereof

A technology of composite materials and catalysts, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve secondary pollution and other problems, achieve good activity, reduce secondary pollution Secondary pollution, good low-temperature catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

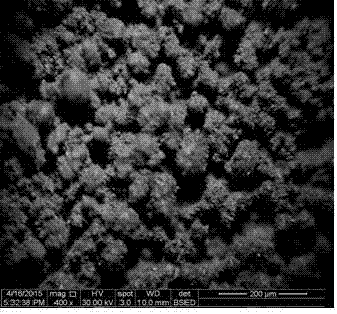

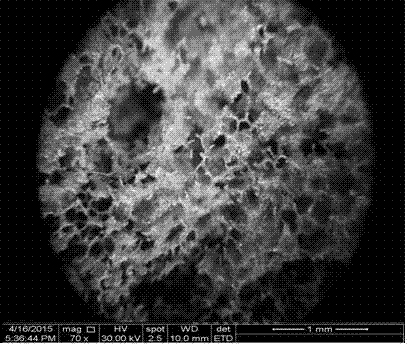

[0032] Take 2 grams of chloropalladium acid and dissolve it in 100mL of water. While stirring, add 100g of D301 macroporous weakly basic styrene-based anion exchange resin and stir evenly. Rinse until no chloride ions in the filtrate can be detected with silver nitrate solution, then put the resin in a drying oven at 60°C to dry.

[0033] Al with an average particle size of 5 microns 2 o 3 12g of the powder is slurried with a 3% aqueous solution of methyl cellulose, ground into a uniform slurry with an agglomerated particle size of less than 30 microns with a three-roller mill, and the above-mentioned macroporous resin that has adsorbed precious metals is used for slurry roll coating and dried 30 minutes.

[0034] Use nano palladium black 0.8g to carry out rolling on Al 2 o 3 The surface layer of the film was dried at 180°C for 12 hours. Put the above resin into a muffle furnace heated to 700°C to burn and volatilize for 1-8 hours, and then reduce it in a hydrogen atmosph...

Embodiment 2

[0036]Take 2.2 grams of chloroplatinic acid and dissolve it in 100 mL of water. Under stirring, add 100 g of D301 macroporous weakly basic styrene-based anion exchange resin and stir evenly. The solution changes from orange to colorless and transparent. Separate the solid and liquid, and use Rinse with a small amount of water until no chloride ions are detected in the filtrate with silver nitrate solution, then put the resin into a drying oven at 60°C to dry.

[0037] CeO with an average particle size of 1 μm 2 -Al 2 o 3 12g of the powder is slurried with a 3% aqueous solution of methyl cellulose, ground into a uniform slurry with an agglomerated particle size of less than 30 microns with a three-roller mill, and the above-mentioned macroporous resin that has adsorbed precious metals is used for slurry roll coating and dried 30 minutes.

[0038] Use nano-platinum black 0.8g to carry out rolling on Al 2 o 3 The surface layer of the film was dried at 180°C for 12 hours. Pu...

Embodiment 3

[0040] Get 1.245 grams of chloroplatinic acid, 0.936 gram of chloropalladic acid and dissolve it in a certain amount of water. Under stirring, add 100 g of D301 macroporous weakly basic styrene-based anion exchange resin and stir evenly. The solution turns from orange red to colorless and transparent. , separate the solid and liquid, rinse with a small amount of water until no chloride ions in the filtrate can be detected with silver nitrate solution, and then put the resin in a drying oven at 60°C to dry.

[0041] CeO with an average particle size of 1 μm 2 -Al 2 o 3 12g of the powder is made into a slurry with an aqueous solution of methyl cellulose (methyl cellulose 3%), and ground into a uniform slurry with an agglomerated particle size of less than 30 microns with a three-roll mill, and the above-mentioned macroporous resin that has adsorbed precious metals is subjected to slurry rolling Apply and let dry for 30 minutes.

[0042] Use 0.400g of nano-platinum black and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com