Control system for lockhole effect TIG deep penetration welding welder and control method

A control system and effect technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of complex welding torch design, sensitive changes in welding parameters, high welding costs, etc., achieve huge industrial application value and improve welding efficiency , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

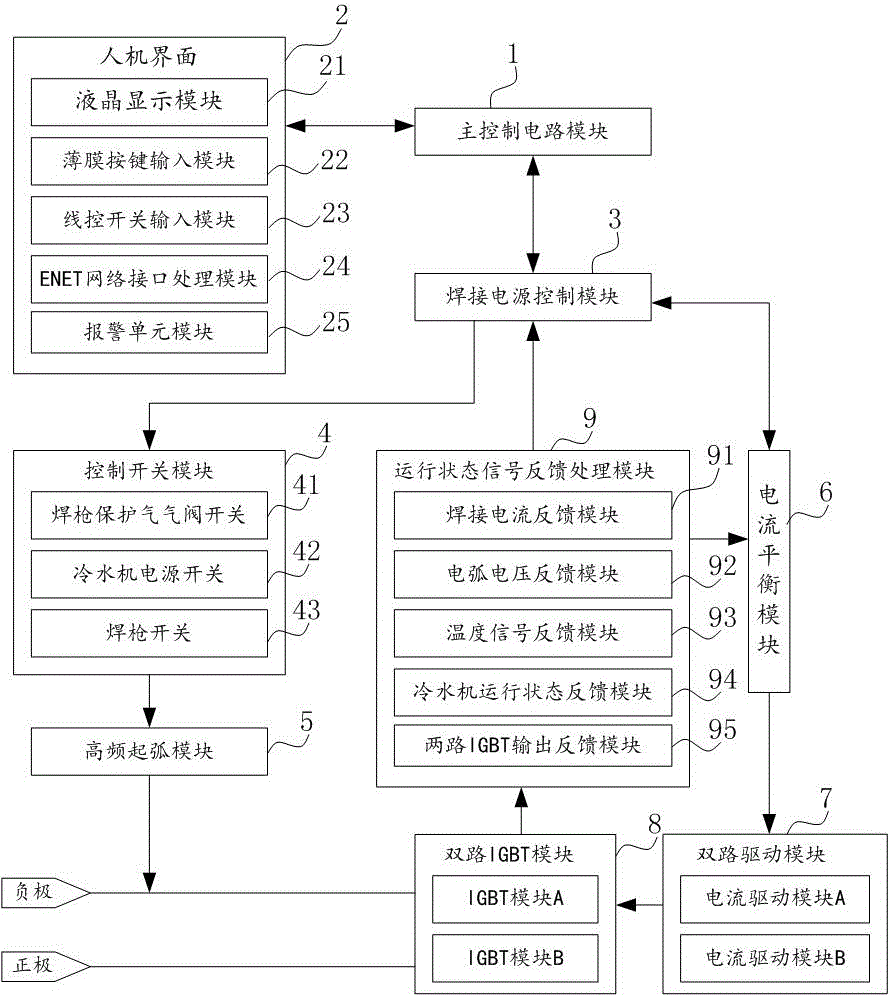

[0029] refer to figure 1 The schematic block diagram of the structure of this embodiment is shown.

[0030] In this embodiment, a keyhole effect TIG deep penetration welding machine control system is a control system designed for the applicant's invention patent: keyhole effect TIG deep penetration welding torch (patent number: 201420318497.7), including Main control circuit module 1, human-machine interface 2, welding power supply control module 3, control switch module 4, high-frequency arc starting module 5, current balance module 6, dual-channel drive module 7, dual-channel IGBT module 8, operating status signal feedback Processing module 9.

[0031] The main control circuit module 1 includes a 32-bit high-speed ARM microprocessor storage unit and a peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com