A planting rockery

A technology of rockery and vegetation holes, which is applied in the field of municipal environmental engineering, can solve the problems of limited appearance, low vegetation and greening functions, and poor construction, and achieve the effects of flexible grass planting time, saving raw materials, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

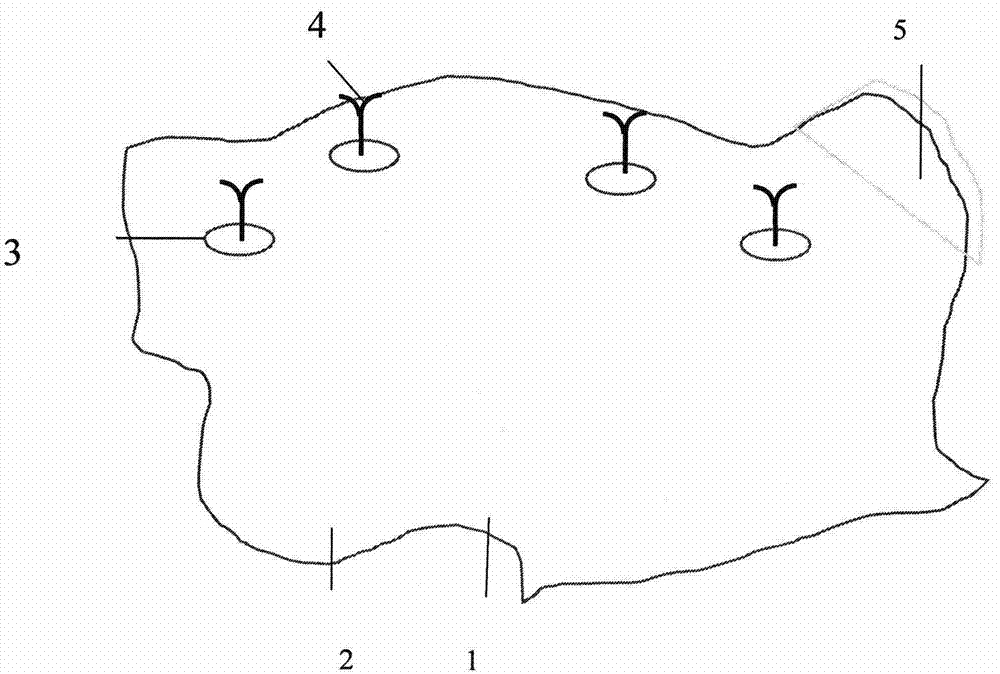

[0024] A planting rockery, comprising a shell, drainage holes, planting holes, planting grass and fillers, the shell is a colored all-light aggregate fiber concrete shell, the filler is foamed ceramsite cement soil filler, and the rockery is made of colored all-light The concrete shell is composed of ceramsite foam cement soil, drainage holes are set at the bottom of the rockery, and planting holes are set on the surface.

Embodiment 2

[0026] A planting artificial rock, comprising a shell, drainage holes, planting holes, planting grass and fillers, the shell is a colored all-light aggregate fiber concrete shell, the filler is ceramsite foam cement soil filler, and the colored all-light bone Fiber-reinforced concrete components include aggregate, fiber, cement, steel wire mesh and water reducer. The aggregate is ceramsite and ceramsite with a bulk density of 500kg / m3 to 1000kg / m3. The fiber is high elastic modulus organic Fiber or alkali-resistant glass fiber, the cement is one of white cement, sulphoaluminate cement or ordinary Portland cement, and the water reducing agent is a high-efficiency water reducing agent with a water reducing rate of more than 25%. The compressive strength of concrete is above 30MPa.

[0027] Construction process and working principle:

[0028] The main raw materials used are: cement is one of white cement, sulphoaluminate cement or ordinary Portland cement, the aggregate is ceram...

Embodiment 3

[0032] A planting artificial rock, comprising a shell, drainage holes, planting holes, planting grass and fillers, the shell is a colored all-light aggregate fiber concrete shell, which is prepared according to the following method: the steel wire mesh is made into a pre-conceived shape , mix cement, pigment, ceramsite, ceramsite, coagulant, fiber and water according to the weight ratio of 50:3:10:20:5:2:100, stir evenly, and spray it on the steel wire mesh by wet mixing spray method Quick-setting into a shell; the cement is one of white cement, sulphoaluminate cement or ordinary Portland cement; the bulk density of the ceramsite or ceramsite is 500kg / m3~1000kg / m3; the coagulation-accelerating The agent is sodium silicate; the fiber is high elastic modulus organic fiber or alkali-resistant glass fiber; the performance of the shell material is good: concrete compressive strength: 122MPa; concrete flexural strength: 15.1MPa; : None; Freeze-thaw resistance: 100 freeze-thaw cycles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com