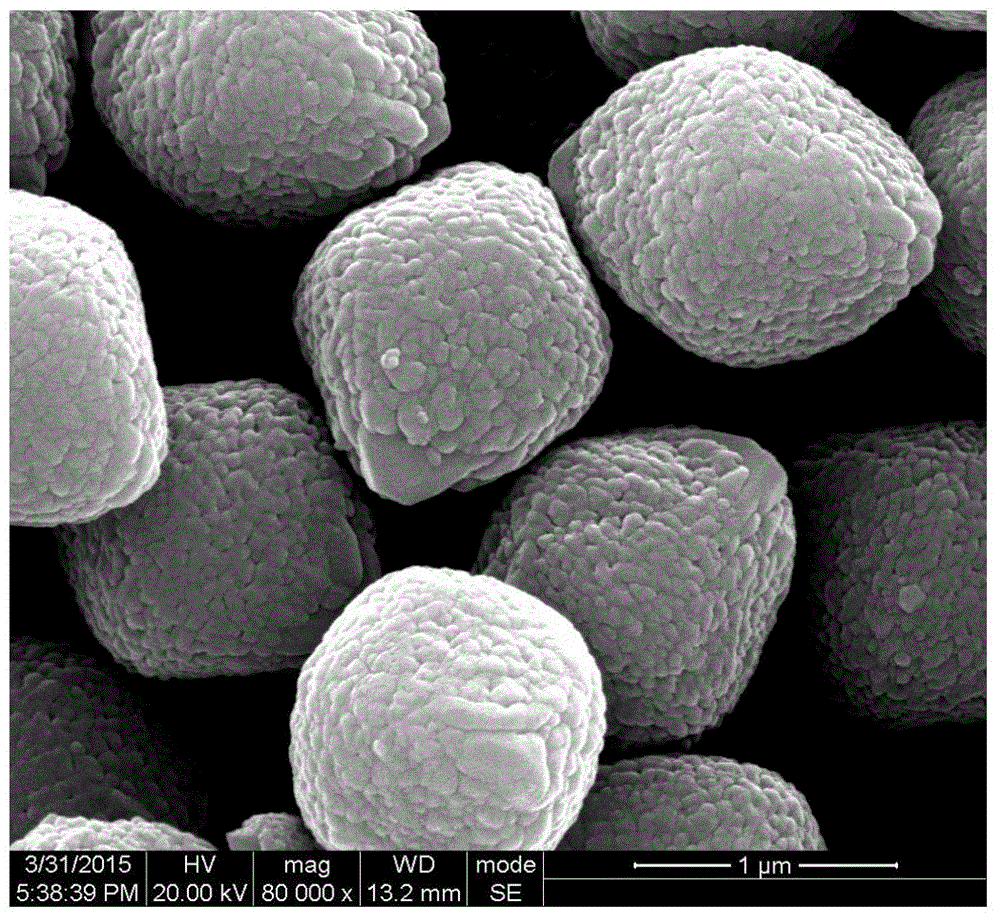

A kind of micron rugby-shaped iron oxide material and preparation method thereof

A football-shaped, iron oxide technology, applied in the directions of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of no reports, etc., and achieve the effects of uniform scale, strong controllability, dense particles and no pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

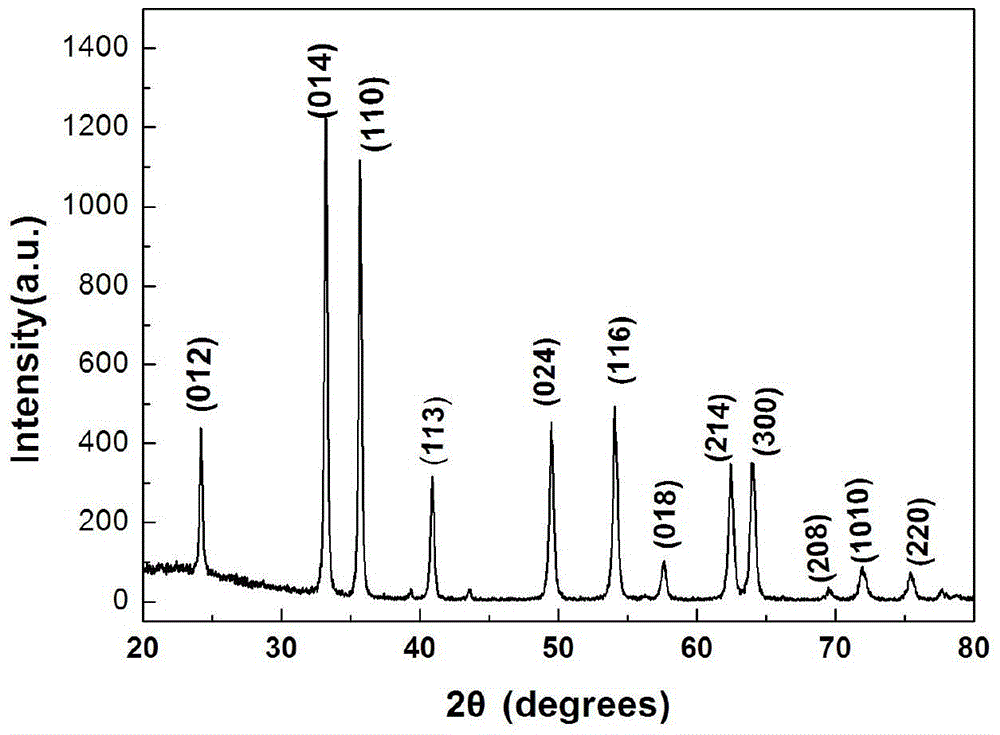

Embodiment 1

[0021] Add 1.36g of sodium dodecylsulfonate into 20ml of deionized water, heat to 60°C and stir to dissolve completely, and obtain a sodium dodecylsulfonate solution with a concentration of 0.25mol / L. Weigh 8.109g FeCl 3 ·6H 2 O was added into 100ml of deionized water and stirred thoroughly to obtain a 0.3mol / L ferric chloride solution. 3 ml of sodium dodecylsulfonate solution were then added dropwise with stirring. Then, 50 ml of 0.3 mol / L NaOH solution was added dropwise under stirring, and stirred again for ten minutes to obtain a red transparent solution. The solution obtained above was transferred to a polytetrafluoroethylene-lined reaction kettle, and reacted at 170°C for 8 hours to obtain a reddish-brown precipitate of iron oxide. The product after the hydrothermal reaction was filtered, washed three times with deionized water and ethanol, and then dried at 110° C. to obtain a reddish-brown iron oxide powder. The reddish-brown iron oxide powder was calcined at 400°C...

Embodiment 2

[0023] Add 1.36g of sodium dodecylsulfonate into 20ml of deionized water, heat to 60°C and stir to dissolve completely, and obtain a sodium dodecylsulfonate solution with a concentration of 0.25mol / L. Weigh 16.218g FeCl 3 ·6H 2 O was added into 100ml of deionized water and stirred thoroughly to obtain a 0.6mol / L ferric chloride solution. Then 5 ml of sodium dodecylsulfonate solution were added dropwise with stirring. Then 100 ml of 0.3 mol / L NaOH solution was added dropwise, and stirred again for ten minutes to obtain a red transparent solution. The solution obtained above was transferred to a polytetrafluoroethylene-lined reaction kettle, and reacted at 180° C. for 6 hours to obtain a reddish-brown precipitate of iron oxide. The product after the hydrothermal reaction was filtered, washed three times with deionized water and ethanol, and then dried at 110° C. to obtain a reddish-brown iron oxide powder. The reddish-brown iron oxide powder was calcined at 350°C for 1 hour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com