Preparation method of fly ash based polymer concrete

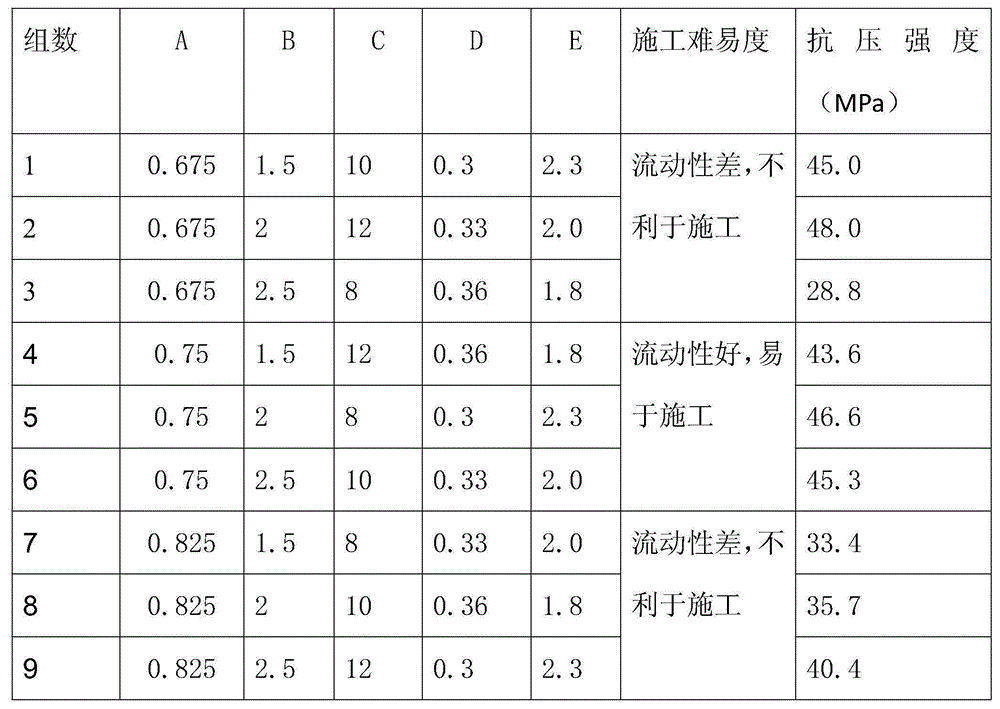

A technology of fly ash and polymer is applied in the field of preparation of fly ash-based polymer concrete, which can solve the problems of polymer concrete not being widely used, incomplete hardening of polymer concrete, and low chemical activity of fly ash. , to achieve the best polymerization effect, good solidification time, and the effect of being conducive to construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of fly ash-based polymer concrete, comprising the following steps:

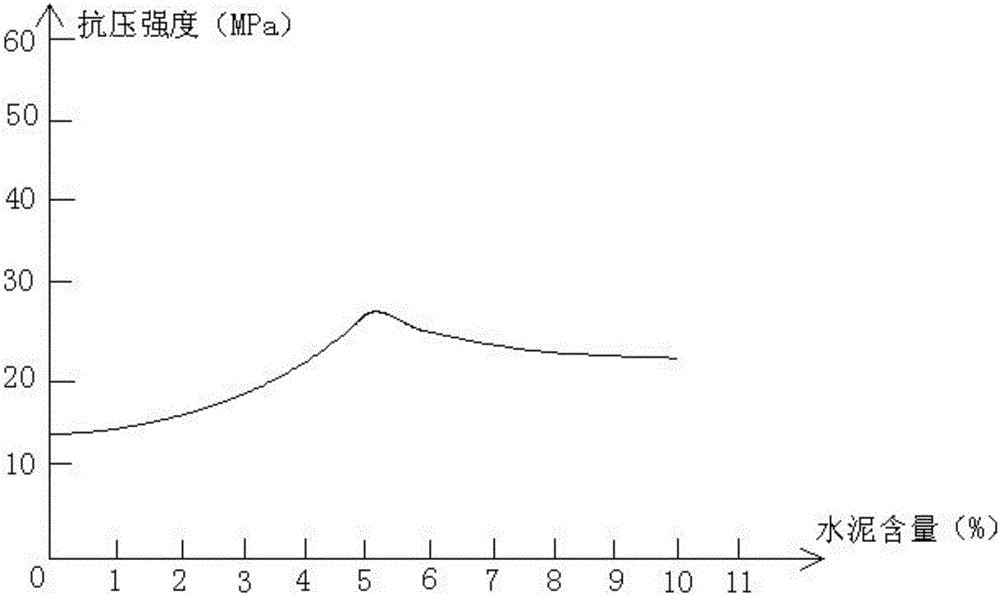

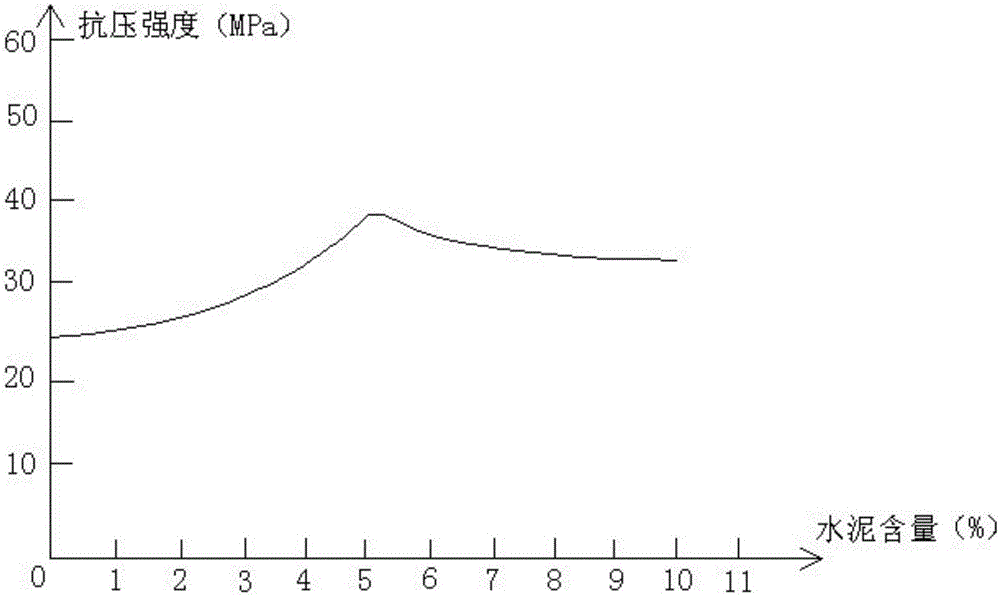

[0029] (1) Mix uniformly 1% cement and 99% fly ash by mass to obtain powder, the fly ash is low-calcium fly ash, the content of calcium oxide in the low-calcium fly ash is less than 10%, silicon The mass ratio of element and aluminum element is 1;

[0030] (2) Put the coarse aggregate and fine aggregate into the mixer according to the mass ratio of 9:5 and stir for 1 minute, then add the powder obtained in step (1) into the mixer, mix the powder and aggregate for 1 minute ;

[0031] Among them, the particle size of coarse aggregate is 10mm, and the bulk density is 1400kg / m 3 , the apparent density is 2600kg / m 3 , the moisture content is 0.3%; the particle size of the fine aggregate is 2mm, and the bulk density is 1300kg / m 3 , the apparent density is 2300kg / m 3 , moisture content is 0.1%.

[0032] (3) Add the alkali excitation liquid into the mixer, and mix and stir the alkali...

Embodiment 2

[0040] A preparation method of fly ash-based polymer concrete, comprising the following steps:

[0041] (1) Mixing 5% cement and 95% fly ash evenly to obtain powder, the fly ash is low-calcium fly ash, the content of calcium oxide in the low-calcium fly ash is less than 10%, silicon The mass ratio of element and aluminum element is 1;

[0042] (2) Put the coarse aggregate and fine aggregate into the agitator according to the mass ratio of 7:3 and stir for 2 minutes, then add the powder obtained in step (1) into the agitator, and the powder, coarse aggregate, fine bone Mix and stir for 2 minutes;

[0043] Among them, the particle size of coarse aggregate is 15mm, and the bulk density is 1450kg / m 3 , the apparent density is 2640kg / m 3 , the moisture content is 0.4%; the particle size of the fine aggregate is 3mm, and the bulk density is 1340kg / m 3 , the apparent density is 2360kg / m 3 , moisture content is 0.2%.

[0044] (3) Add the alkali excitation liquid into the mixer, ...

Embodiment 3

[0052] A preparation method of fly ash-based polymer concrete, comprising the following steps:

[0053] (1) Mixing 9% cement and 91% fly ash evenly by mass to obtain powder, the fly ash is low-calcium fly ash, and the content of calcium oxide in the low-calcium fly ash is less than 10%, silicon The mass ratio of element and aluminum element is 1;

[0054] (2) Put the coarse aggregate and fine aggregate into the agitator according to the mass ratio of 2:1 and stir for 2 minutes, then add the powder obtained in step (1) into the agitator. Mix and stir for 2 minutes;

[0055] Among them, the particle size of coarse aggregate is 22mm, and the bulk density is 1500kg / m 3 , the apparent density is 2700kg / m 3 , the moisture content is 0.5%; the particle size of the fine aggregate is 4mm, and the bulk density is 1400kg / m 3 , the apparent density is 2400kg / m 3 , moisture content is 0.3%.

[0056] (3) Add the alkali excitation liquid into the mixer, and mix and stir the alkali exci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com