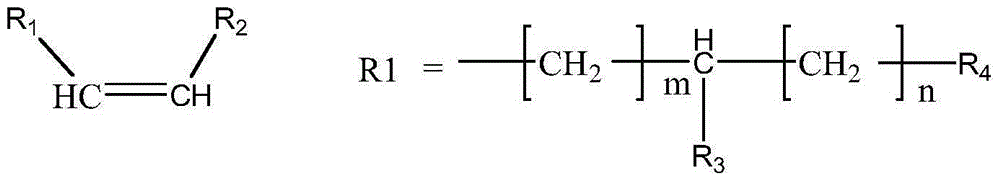

Alkylaromatic hydrocarbon substituted ethylene monomer-containing oil-soluble polymer viscosity reducer and microwave preparation method thereof

A technology of oil-soluble viscosity reducer and alkyl aromatic hydrocarbon, applied in the field of oil-soluble viscosity reducer, can solve the problem of no heavy oil, high-efficiency viscosity-reducing agent, etc., to reduce viscosity, demonstrate technological progress, and improve the energy efficiency of pipeline transportation and operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

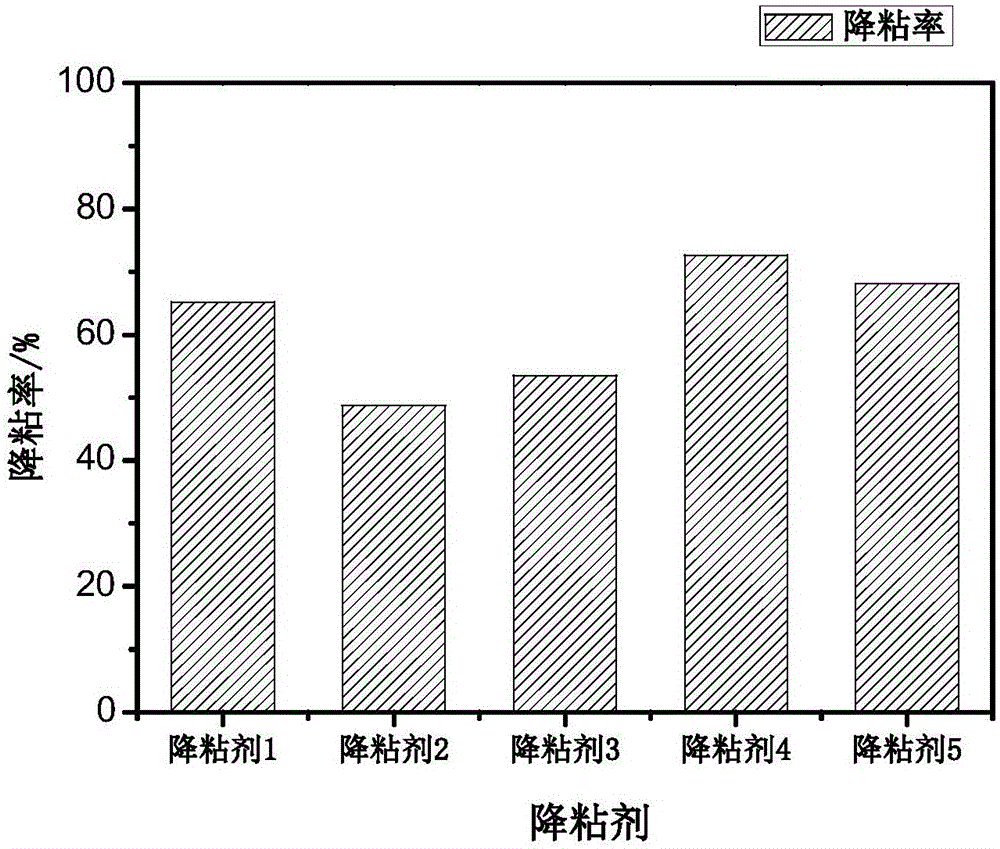

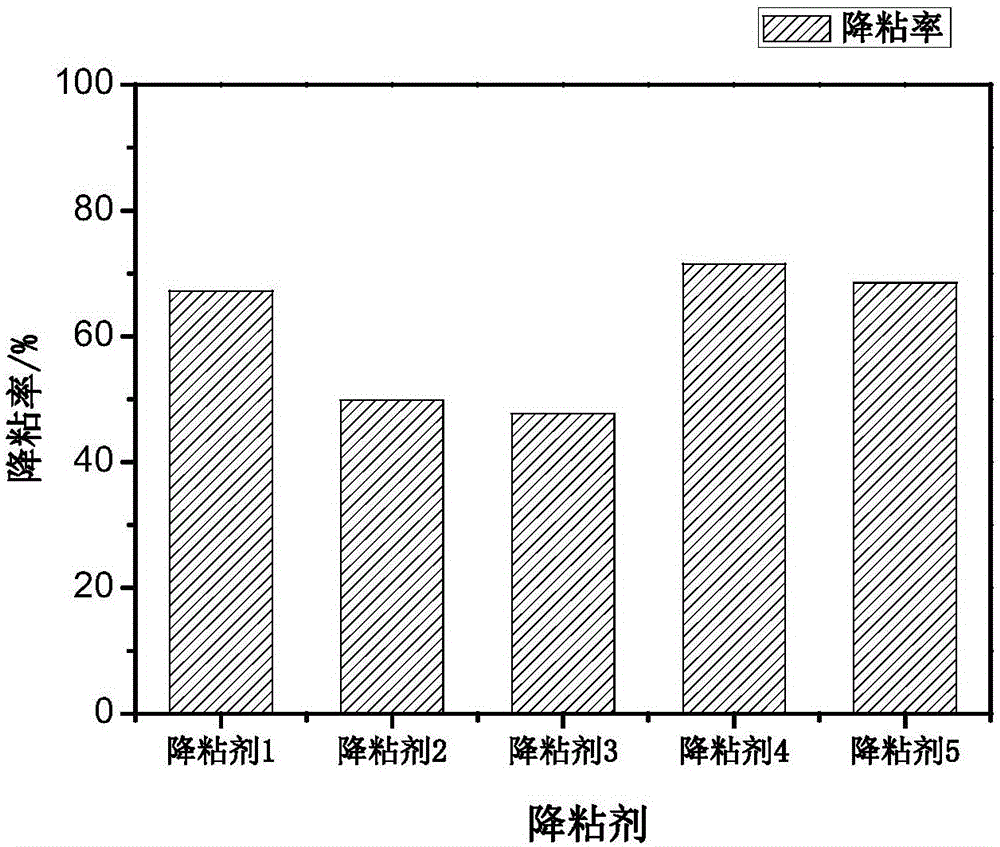

Examples

Embodiment 1

[0038] (1) Perform binary polymerization of monomer 1 and monomer 2 in proportion, after accurate weighing, add to a quartz microwave reaction tube, add a reaction solvent, fully stir the reactants, and all the reactants are dissolved in the solvent.

[0039] (2) Add the initiator in proportion, purge the reactor with nitrogen, and close the reactor. Raise the temperature to 90°C and react for 1.0h.

[0040] (3) After the reaction is over, after cooling, under the condition of rapid stirring, slowly drop the reaction product into a large amount of solvent with a dropper, and rinse the reactor with a small amount of reaction solvent, transfer the remaining product into a large amount of methanol, and stir for 2 hours , so that all the polymer is precipitated.

[0041] (4) After the stirring is completed, suction filtration is carried out with a Buchner funnel, dried in the air, and weighed to obtain a polymer.

[0042] (5) Dissolve the viscosity reducer in a certain solvent t...

Embodiment 2

[0051] (1) Perform binary polymerization of monomer 1 and monomer 2 in proportion, after accurate weighing, add to a quartz microwave reaction tube, add a reaction solvent, fully stir the reactants, and all the reactants are dissolved in the solvent.

[0052] (2) Add the initiator in proportion, purge the reactor with nitrogen, and close the reactor. Raise the temperature to 120°C and react for 1.5h.

[0053] (3) After the reaction is over, after cooling, under the condition of rapid stirring, slowly drop the reaction product into a large amount of solvent with a dropper, and rinse the reactor with a small amount of reaction solvent, transfer the remaining product into a large amount of methanol, and stir for 2 hours , so that all the polymer is precipitated.

[0054] (4) After the stirring is completed, suction filtration is carried out with a Buchner funnel, dried in the air, and weighed to obtain a polymer.

[0055] (5) Dissolve the viscosity reducer in a certain solvent ...

Embodiment 3

[0064] (1) Perform binary polymerization of monomer 1 and monomer 2 in proportion, after accurate weighing, add to a quartz microwave reaction tube, add a reaction solvent, fully stir the reactants, and all the reactants are dissolved in the solvent.

[0065] (2) Add the initiator in proportion, purge the reactor with nitrogen, and close the reactor. Raise the temperature to 90°C and react for 1.0h.

[0066] (3) After the reaction is over, after cooling, under the condition of rapid stirring, slowly drop the reaction product into a large amount of solvent with a dropper, and rinse the reactor with a small amount of reaction solvent, transfer the remaining product into a large amount of methanol, and stir for 2 hours , so that all the polymer is precipitated.

[0067] (4) After the stirring is completed, suction filtration is carried out with a Buchner funnel, dried in the air, and weighed to obtain a polymer.

[0068] (5) Dissolve the viscosity reducer in a certain solvent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com