Modification method for nanometer titania

A nano-titanium dioxide and modification technology, applied in the direction of dyeing low-molecular-weight organic compounds, fibrous fillers, etc., can solve the problems of uniform dispersion, nano-titanium dioxide cannot be stably dispersed, and does not have photocatalytic performance, etc., and achieves good technical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

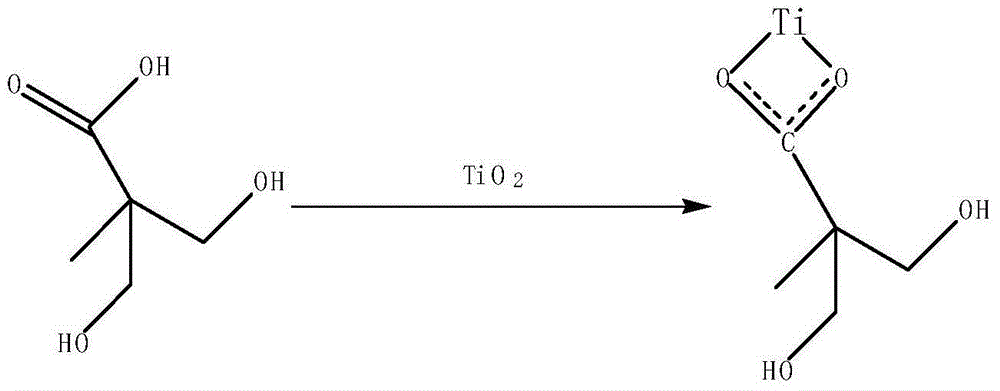

[0021] 2, the preparation method of 2-dimethylolpropionic acid modified nano-titanium dioxide:

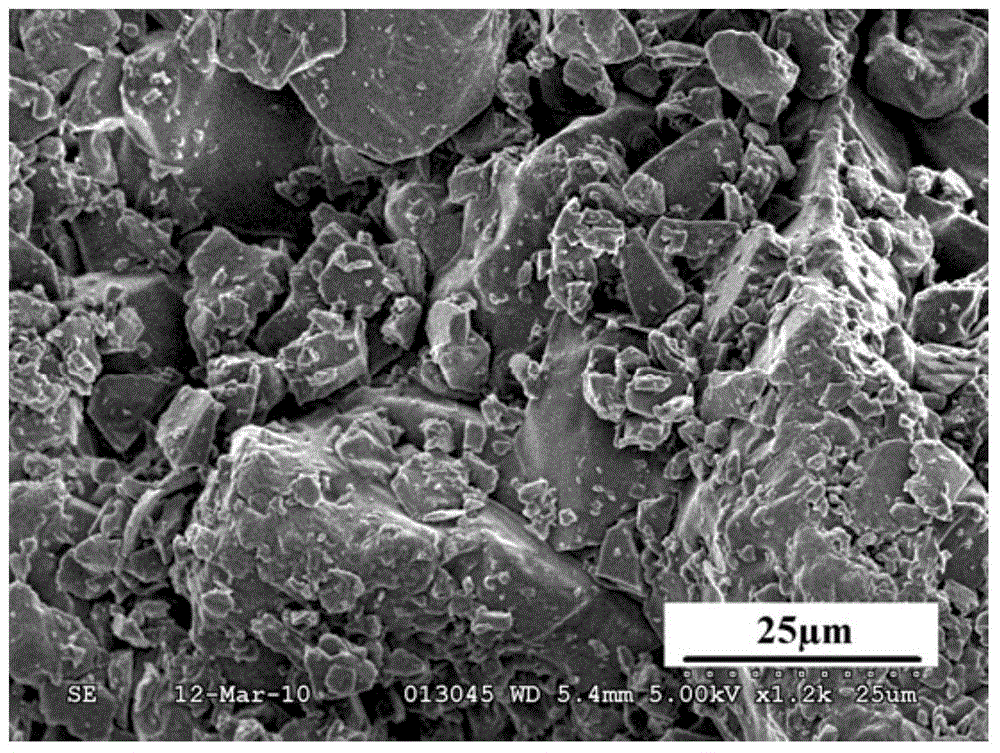

[0022] After calcining, 1g of nano-titanium dioxide (average particle diameter is 500nm) and 4g of dried 2,2-dimethylolpropionic acid (electron microscope as shown in Fig. figure 1 Shown) placed in 45ml isopropanol (35.35g), ultrasonic dispersion treatment for 1 hour;

[0023] Under the protection of dry nitrogen, the reaction was continued at 80°C for 24 hours;

[0024] The solid particles were separated in a centrifuge, and then the separated particles were redissolved in 30ml (23.754g) of methanol, and separated again until the solution was clear;

[0025] The finally separated 2,2-dimethylolpropionic acid-modified nano-titanium dioxide is placed in a vacuum oven for drying treatment.

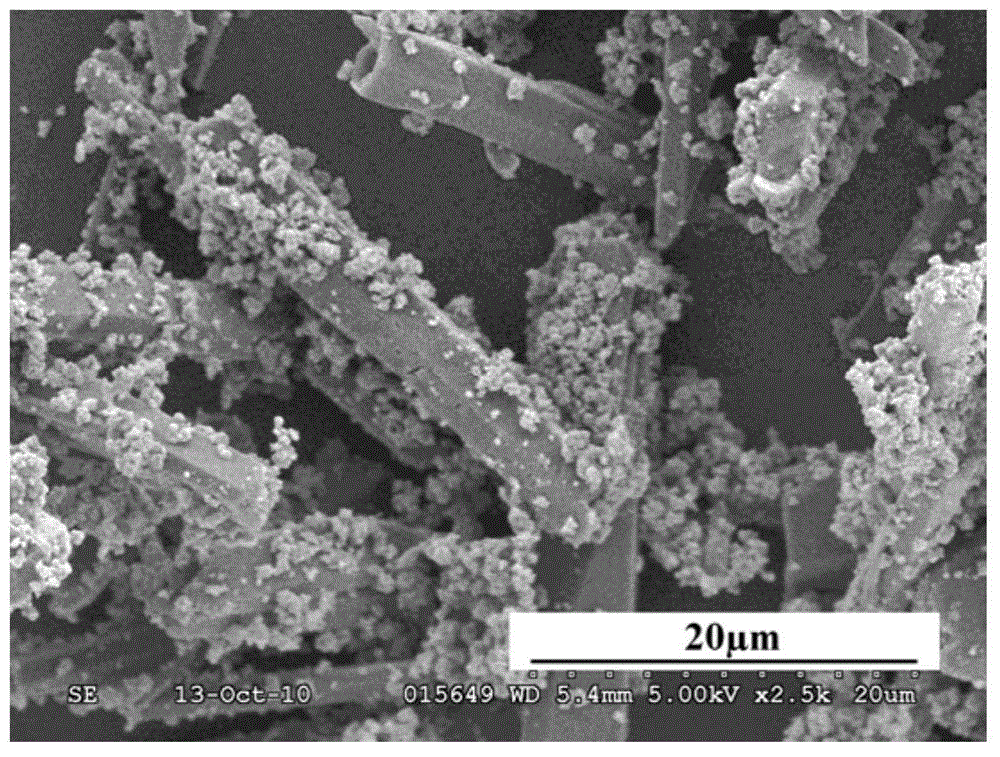

[0026] The 2,2-dimethylolpropionic acid-n-titanium dioxide electron microscope picture after the coordination reaction obtained figure 2 shown.

Embodiment 2

[0028] 2, the preparation method of 2-dimethylolpropionic acid modified nano-titanium dioxide:

[0029] After calcining, place 2g of nano-titanium dioxide (average particle size is 300nm) and 6g of dried 2,2-dimethylolpropionic acid in 60ml of isopropanol, and ultrasonically disperse for 0.5 hour;

[0030] Under the protection of dry nitrogen, the reaction was continued at 70°C for 30 hours;

[0031] Separate the solid particles in a centrifuge, then redissolve the separated particles in 50ml of methanol, and separate again until the solution is clear;

[0032] The finally separated 2,2-dimethylolpropionic acid-modified nano-titanium dioxide is placed in a vacuum oven for drying treatment.

Embodiment 3

[0034] 2, the preparation method of 2-dimethylolpropionic acid modified nano-titanium dioxide:

[0035] After calcining, 1.5g of nano-titanium dioxide (average particle size is 500nm) and 5g of dried 2,2-dimethylolpropionic acid are placed in 50ml of isopropanol, and ultrasonically dispersed for 1.5 hours;

[0036] Under the protection of dry nitrogen, the reaction was continued at 90°C for 20 hours;

[0037] Separate the solid particles in a centrifuge, then redissolve the separated particles in 45ml of methanol, and separate again until the solution is clear;

[0038] The finally separated 2,2-dimethylolpropionic acid-modified nano-titanium dioxide is placed in a vacuum oven for drying treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com