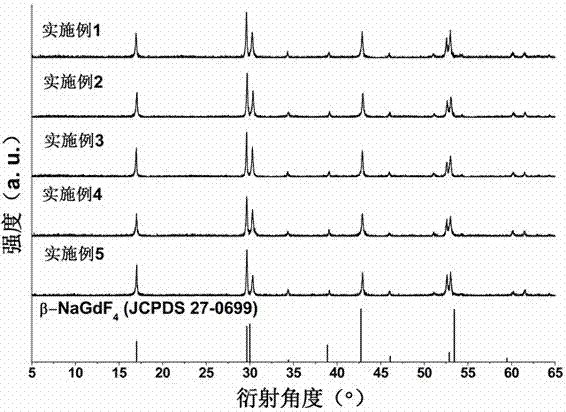

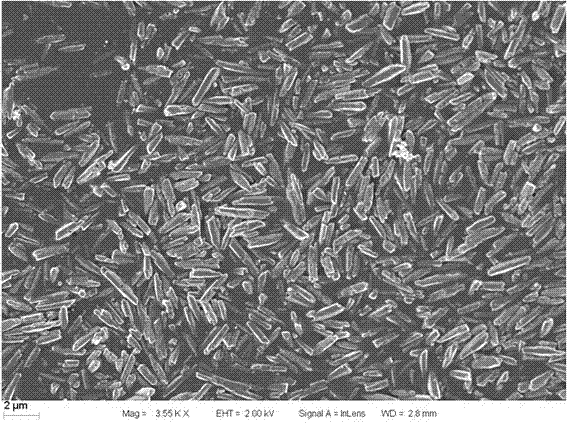

Polyacrylic acid modified rod-shaped monodisperse nagdf 4 :yb 3+ ,er 3+ Upconversion Phosphor

A polyacrylic acid, monodisperse technology, used in luminescent materials, chemical instruments and methods, etc., can solve the problems of complex process, low water solubility, and little research on nanoparticle morphology, and achieve broad application prospects and synthesis technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Measure 3.2mL gadolinium nitrate, 1.7mL ytterbium nitrate, 0.3mL erbium nitrate solution, dissolve in 1.5mL polyacrylic acid solution, mix well to get solution A;

[0030] 2) Weigh 0.252g NaF, dissolve in 10mL ultrapure water, add 0.799g NH 4 HF 2 , and stir evenly to obtain solution B;

[0031] 3) Mix solutions A and B evenly, adjust the pH value to 3 with dilute nitric acid, and obtain solution C;

[0032] 4) Stir the solution C for 15 minutes, then transfer it to a stainless steel reactor with a polytetrafluoroethylene liner and seal it. After a hydrothermal reaction at 200°C for 16 hours, cool to room temperature with the furnace to obtain a precipitate;

[0033]5) Centrifuge the obtained precipitate (rotating speed: 8000r / min), centrifuge time is 5min, and alternately wash 3 times with absolute ethanol and ultrapure water, centrifuge, and then place the cleaned material in an oven at 80°C Dry for 12 hours and grind to obtain polyacrylic acid-modified rod-shap...

Embodiment 2

[0035] 1) Measure 3.2mL gadolinium nitrate, 1.7mL ytterbium nitrate, 0.3mL erbium nitrate solution, dissolve in 3mL polyacrylic acid solution, mix well to get solution A;

[0036] 2) Weigh 0.252g NaF, dissolve in 10mL ultrapure water, add 0.799g NH 4 HF 2 , and stir evenly to obtain solution B;

[0037] 3) Mix solutions A and B evenly, adjust the pH value to 3 with dilute nitric acid, and obtain solution C;

[0038] 4) Stir the solution C for 15 minutes, then transfer it to a stainless steel reactor with a polytetrafluoroethylene liner and seal it. After a hydrothermal reaction at 200°C for 16 hours, cool to room temperature with the furnace to obtain a precipitate;

[0039] 5) Centrifuge the obtained precipitate (rotating speed: 8000r / min), centrifuge time is 5min, and alternately wash 3 times with absolute ethanol and ultrapure water, centrifuge, and then place the cleaned material in an oven at 80°C Dry for 12 hours and grind to obtain polyacrylic acid-modified rod-shape...

Embodiment 3

[0041] 1) Measure 3.2mL gadolinium nitrate, 1.7mL ytterbium nitrate, 0.3mL erbium nitrate solution, dissolve in 4.5mL polyacrylic acid solution, mix well to get solution A;

[0042] 2) Weigh 0.252g NaF, dissolve in 10mL ultrapure water, add 0.799g NH 4 HF 2 , and stir evenly to obtain solution B;

[0043] 3) Mix solutions A and B evenly, adjust the pH value to 3 with dilute nitric acid, and obtain solution C;

[0044] 4) Stir the solution C for 15 minutes, then transfer it to a stainless steel reactor with a polytetrafluoroethylene liner and seal it. After a hydrothermal reaction at 200°C for 16 hours, cool to room temperature with the furnace to obtain a precipitate;

[0045] 5) Centrifuge the obtained precipitate (rotating speed: 8000r / min), centrifuge time is 5min, and alternately wash 3 times with absolute ethanol and ultrapure water, centrifuge, and then place the cleaned material in an oven at 80°C Dry for 12 hours and grind to obtain polyacrylic acid-modified rod-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com