Method and device for remelting and refining metals by vacuum magnetic-control arc

A vacuum arc remelting and arc remelting technology, which is applied in the field of electromagnetic metallurgy secondary refining, can solve the problems of severe heating of anode and cathode surfaces, loss of alloy composition, influence of metallurgical quality, etc., so as to prevent metallurgical quality from being affected and inhibit melting and vaporization. , the effect of delaying ion starvation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention are described in detail as follows:

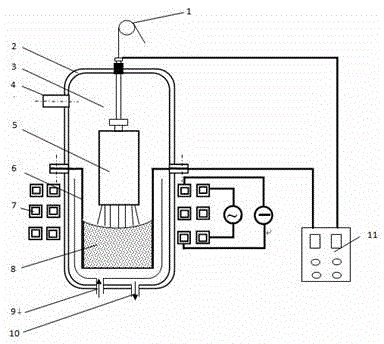

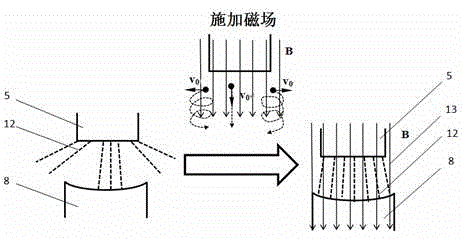

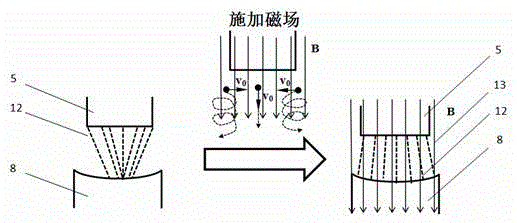

[0032] In this example, see Figure 1 to Figure 5 , a vacuum arc remelting device, comprising an electrode feeding mechanism 1, a vacuum cover 2, an air extraction hole 4, a water-cooled copper mold crystallizer 6, a crystallizer cooling water jacket device and a power supply 11, the power supply 11 adopts a voltage-regulated DC power supply, and the vacuum The cover 2 is used as the outer shell of the vacuum arc remelting device to form a vacuum chamber 3. The air extraction hole 4 is arranged on the vacuum cover 2. The vacuum chamber 3 is connected to the vacuum pump through the air extraction hole 4. During the metal remelting process, the vacuum chamber 3 is continuously evacuated. The metal electrode rod 5 to be remelted and refined is installed on the bottom fixed end of the electrode feeding mechanism 1 in the vacuum chamber 3 as a consumable electrode, and the metal electrode ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com