Lignite drying process and system

A drying process and drying system technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of waste of steam resources, low output of drying furnace materials, low drying capacity, etc., and achieve metal consumption and investment Small size, improved working environment, strong drying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

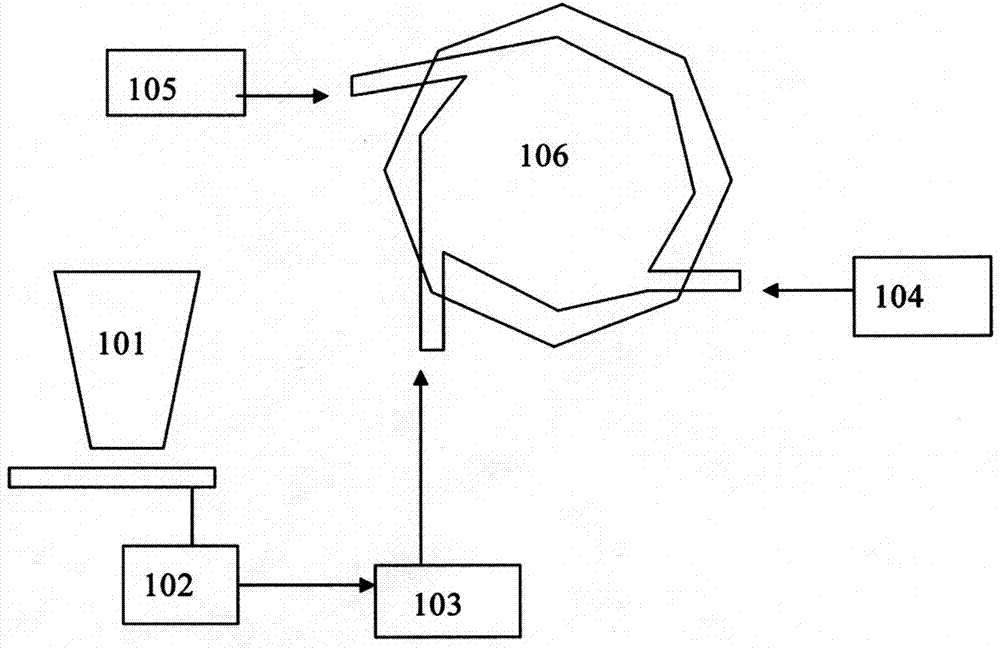

[0039]Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, technological process of the present invention is:

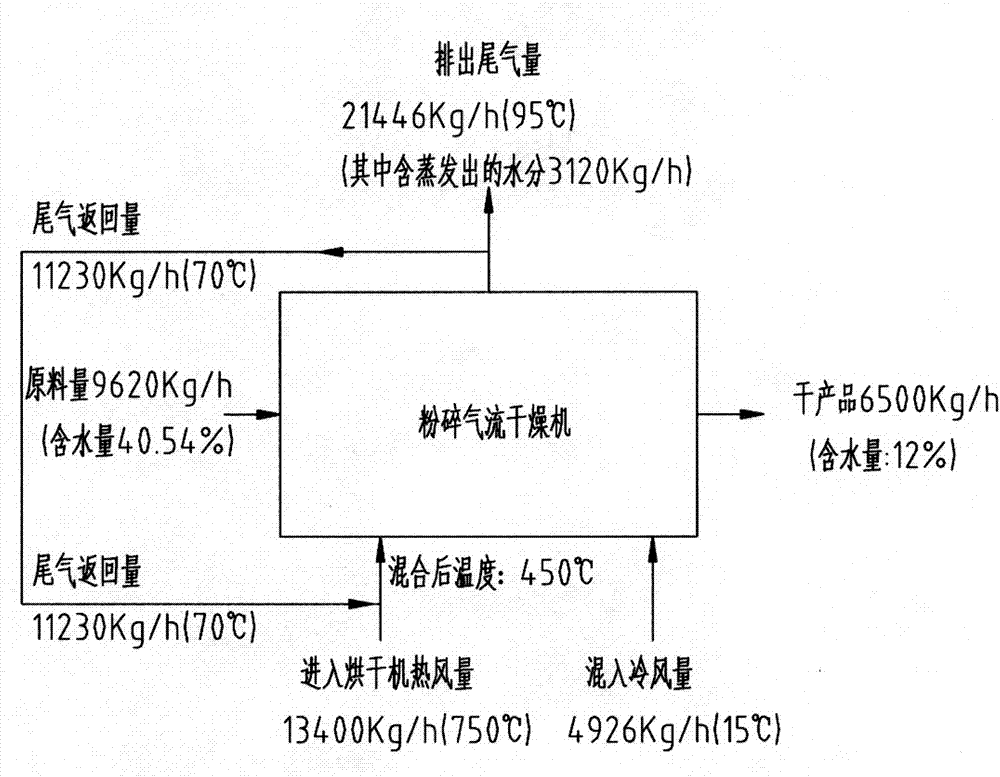

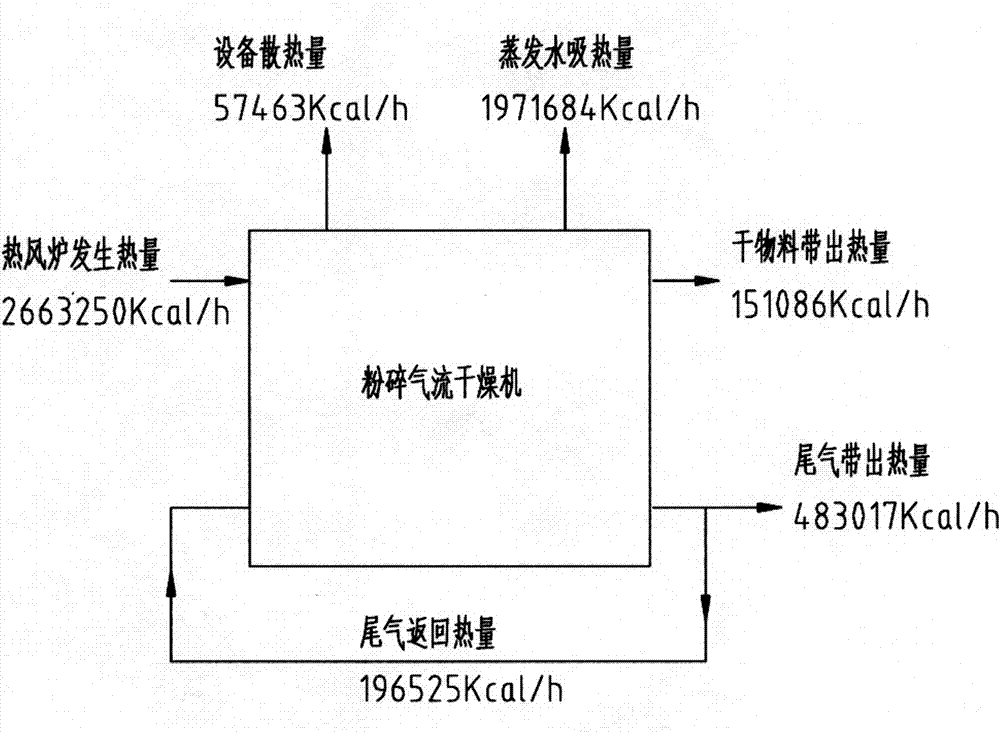

[0040] The lignite drying process is characterized in that wet coal powder coarsely crushed into 0.5-30mm particles, with a moisture content of 30%-40% and a temperature of 15°C enters the belt feeder 202 from the raw material bin 201 which can control the thickness of the material layer , the material flow of the same thickness enters the jet mill 301 from the belt feeder 202, and here it fully contacts with the 350°C-450°C hot air from the cyclone burner 106. The excess air coefficient is controlled at 2.5, and each part of the system contains oxygen. The amount is less than 12%, and it is dried while being crushed. The dried material and exhaust gas are sucked into the single-cylinder cyclone receiver 401 for materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com