Water-dispersible leaf surface affiliative type nano pesticide slow releasing agent and preparation method thereof

A slow-release agent and pesticide technology, applied in the field of pesticides, can solve the problems of large free surface energy of particles, unstable kinetics, precipitation and agglomeration, etc., and achieve the effect of extending the duration of sustained release, reducing the amount of pesticides used, and solving aggregation and sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

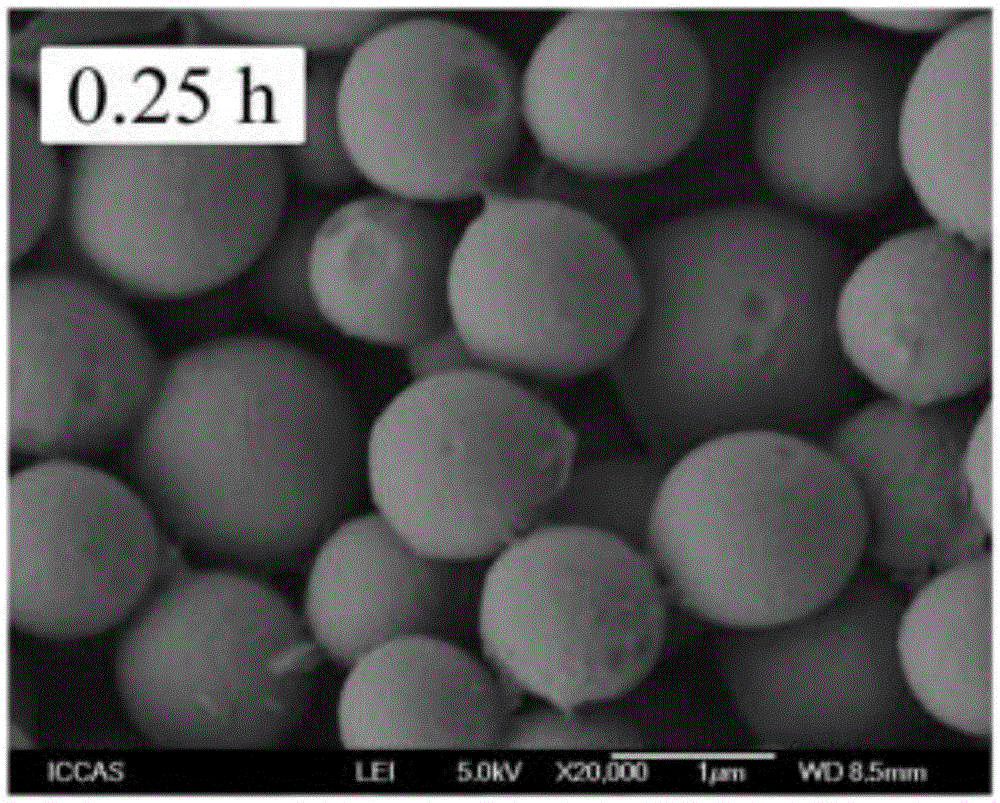

[0048] Embodiment 1, preparation microcapsule type water-based suspending agent

[0049] Prepare the microcapsule type water-based suspension according to the following steps:

[0050] (1) Sodium hydroxide is dissolved in a mixed solvent of ethanol and water with a volume ratio of 1:50 to form a sodium hydroxide solution with a concentration of 80 mg / ml;

[0051] (2) Disperse the PLA (molecular weight of 100,000) microcapsules loaded with chlorantraniliprole in the loaded core into the sodium hydroxide solution prepared in step (1) to obtain a suspension with a mass concentration of 4 mg / ml;

[0052] (3) Shake the suspension prepared in step (2) at 100 r / min for 15 min. Finally, the suspension was centrifuged at 3000 r / min for 5 min to collect the product. The resulting product was washed 3 times with water and freeze-dried.

[0053] The scanning electron micrograph of the microcapsule prepared in this embodiment is as follows: figure 1 shown.

Embodiment 2

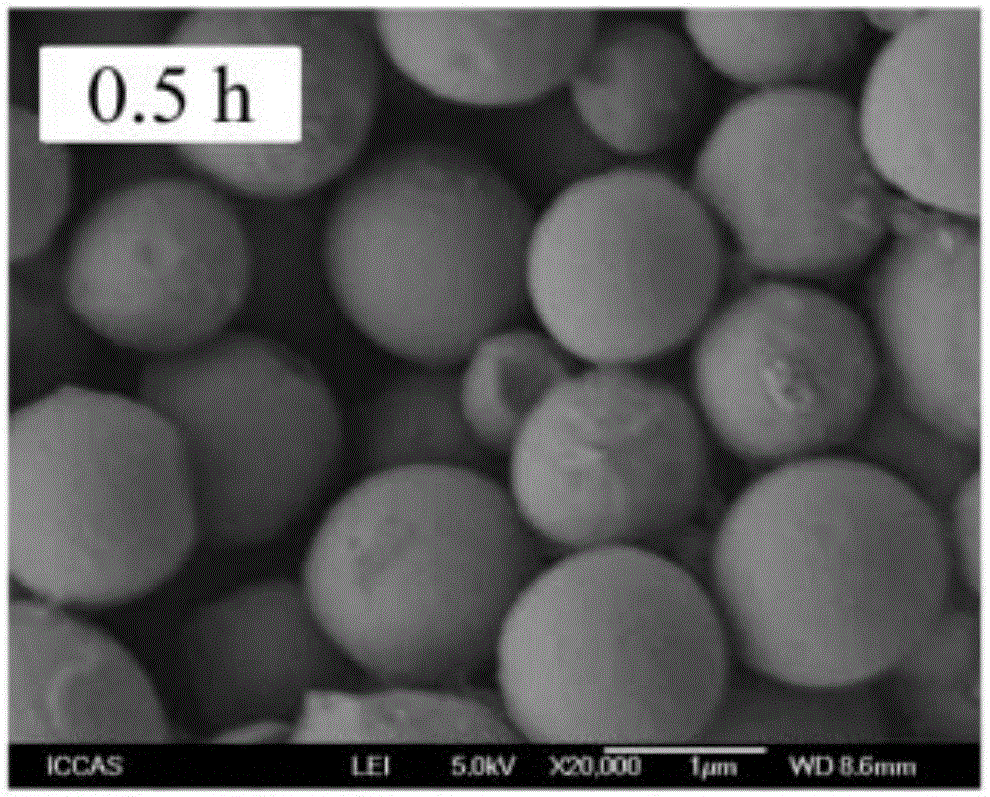

[0054] Embodiment 2, preparation microcapsule type water-based suspending agent

[0055] Prepare the microcapsule type water-based suspension according to the following steps:

[0056] (1) Sodium hydroxide is dissolved in a mixed solvent of ethanol and water with a volume ratio of 1:50 to form a sodium hydroxide solution with a concentration of 80 mg / ml;

[0057] (2) Dispersing the PLA (molecular weight of 100,000) microcapsules loaded with chlorantraniliprole on the inner core in the sodium hydroxide solution prepared in step (1) to obtain a suspension with a mass concentration of 4 mg / ml;

[0058] (3) Shake the suspension B prepared in step (2) at 100 r / min for 30 min. Finally, the suspension was centrifuged at 3000 r / min for 5 min to collect the product. The resulting product was washed 3 times with water and freeze-dried.

[0059] The scanning electron micrograph of the microcapsule prepared in this embodiment is as follows: figure 2 shown.

Embodiment 3

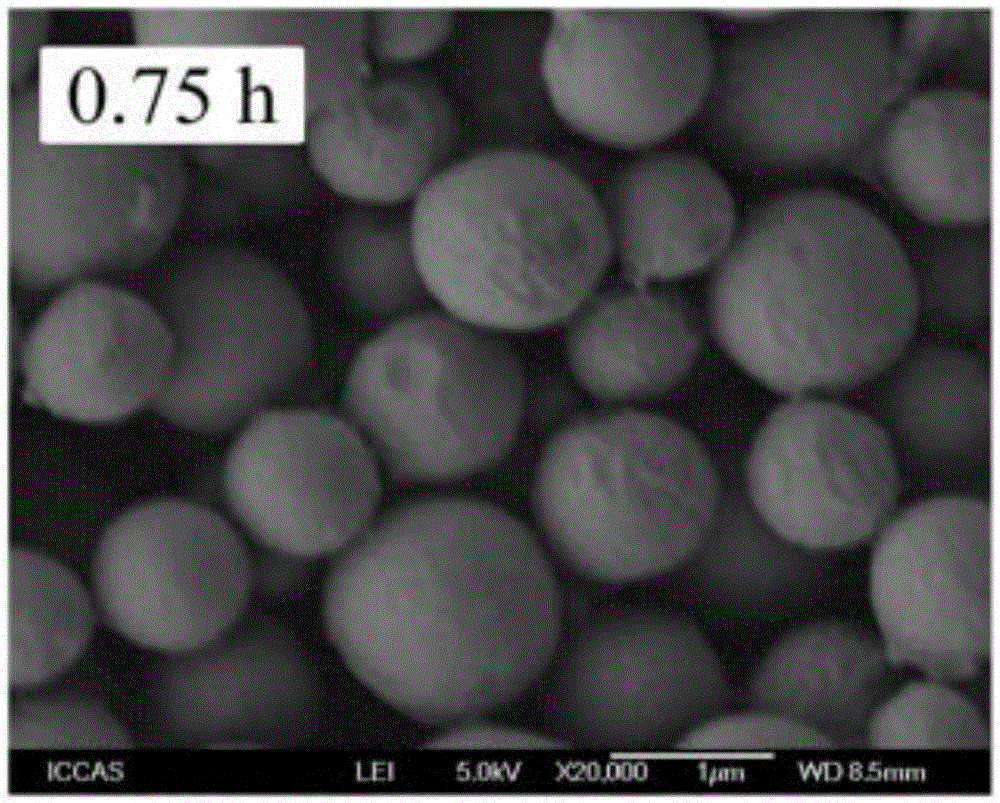

[0060] Embodiment 3, preparation microcapsule type water-based suspending agent

[0061] Prepare the microcapsule type water-based suspension according to the following steps:

[0062] (1) Sodium hydroxide is dissolved in a mixed solvent of ethanol and water with a volume ratio of 1:50 to form a sodium hydroxide solution with a concentration of 80 mg / ml;

[0063] (2) Disperse PLA (molecular weight: 100,000) microcapsules loaded with chlorantraniliprole on the inner core in the sodium hydroxide solution to obtain a suspension with a mass concentration of 4 mg / ml;

[0064] (3) Shake the suspension prepared in step (2) at 100 r / min for 45 min. Finally, the suspension was centrifuged at 3000 r / min for 5 min to collect the product. The resulting product was washed 3 times with water and freeze-dried.

[0065] The scanning electron micrograph of the microcapsule prepared in this embodiment is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com