Candle-ash-assisted super-hydrophobic and super-oleophilic oil-water separation mesh film as well as preparation method and application of mesh film

A super-hydrophobic, off-grid membrane technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of low recycling rate, slow separation rate, application limitations, etc., and achieve low equipment requirements and easy recycling. , the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

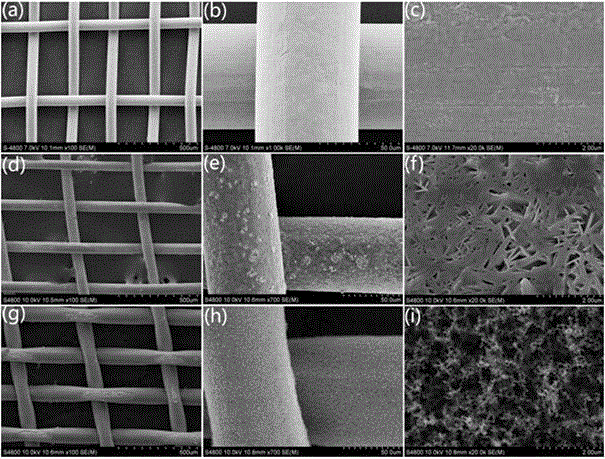

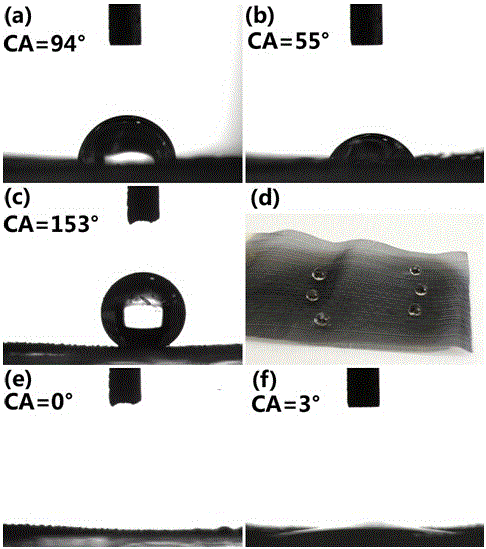

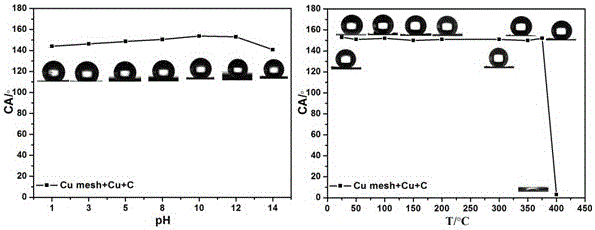

[0041] The preparation method of the superhydrophobic superlipophilic oil-water separation omentum assisted by candle ash described in the present embodiment comprises the following steps:

[0042] 1. Clean the copper mesh with acetone, absolute ethanol and water for 5 minutes, and dry it with compressed nitrogen;

[0043] 2. Weigh 1.4204g of anhydrous sodium sulfate and 1.7048g of copper chloride dihydrate, and prepare 200ml of 0.05mol / L electrolyte solution (the molar concentration of anhydrous sodium sulfate is 0.05mol / L, and the molar concentration of copper chloride dihydrate is 0.05mol / L);

[0044] 3. Place the pretreated copper mesh in the above prepared electrolyte solution, use the platinum sheet as the anode, and the pretreated copper mesh as the cathode, and conduct constant voltage electrodeposition at 0.5V for 6 minutes at a temperature of 25°C;

[0045] 4. Rinse the electrodeposited copper mesh with a large amount of deionized water, and dry it with compressed n...

Embodiment 2

[0054] The preparation method of the superhydrophobic superlipophilic oil-water separation omentum assisted by candle ash described in the present embodiment comprises the following steps:

[0055] 1. Clean the copper mesh with acetone, absolute ethanol and water for 5 minutes, and dry it with compressed nitrogen;

[0056] 2. Weigh 1.4204g of anhydrous sodium sulfate and 1.7048g of copper chloride dihydrate, and prepare 200ml of 0.05mol / L electrolyte solution (the molar concentration of anhydrous sodium sulfate is 0.05mol / L, and the molar concentration of copper chloride dihydrate is 0.05mol / L);

[0057] 3. Place the pretreated copper mesh in the above prepared electrolyte solution, use the platinum sheet as the anode, and the pretreated copper mesh as the cathode, conduct constant voltage electrodeposition at 0.7V for 5 minutes, and the temperature is 30°C;

[0058] 4. Rinse the electrodeposited copper mesh with a large amount of deionized water, and dry it with compressed n...

Embodiment 3

[0063] The preparation method of the superhydrophobic superlipophilic oil-water separation omentum assisted by candle ash described in the present embodiment comprises the following steps:

[0064] 1. Clean the copper mesh with acetone, absolute ethanol and water for 5 minutes, and dry it with compressed nitrogen;

[0065] 2. Weigh 0.7102g of anhydrous sodium sulfate and 0.8524g of copper chloride dihydrate, and prepare 200ml of 0.025mol / L electrolyte solution (the molar concentration of anhydrous sodium sulfate is 0.025mol / L, and the molar concentration of copper chloride dihydrate is 0.025mol / L);

[0066] 3. Place the pretreated copper mesh in the above prepared electrolyte solution, use the platinum sheet as the anode, and the copper mesh as the cathode, conduct constant voltage electrodeposition at 0.8V for 4 minutes, and the temperature is 25°C;

[0067] 4. Rinse the electrodeposited copper mesh with a large amount of deionized water, and dry it with compressed nitrogen;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com