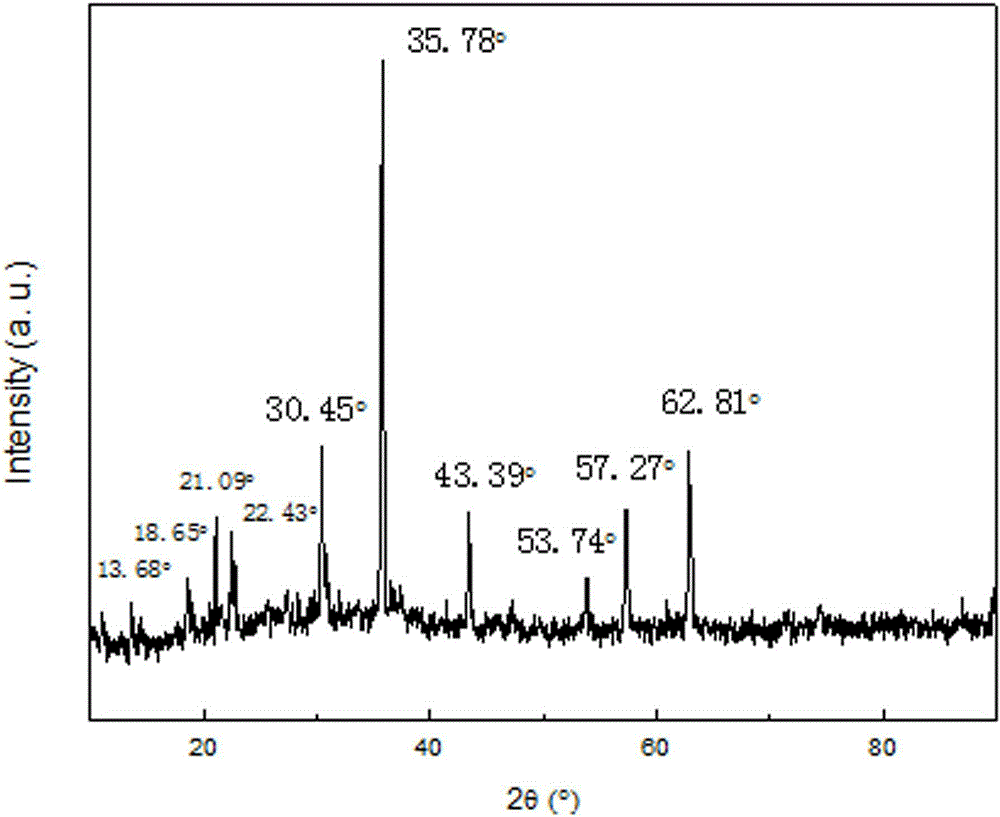

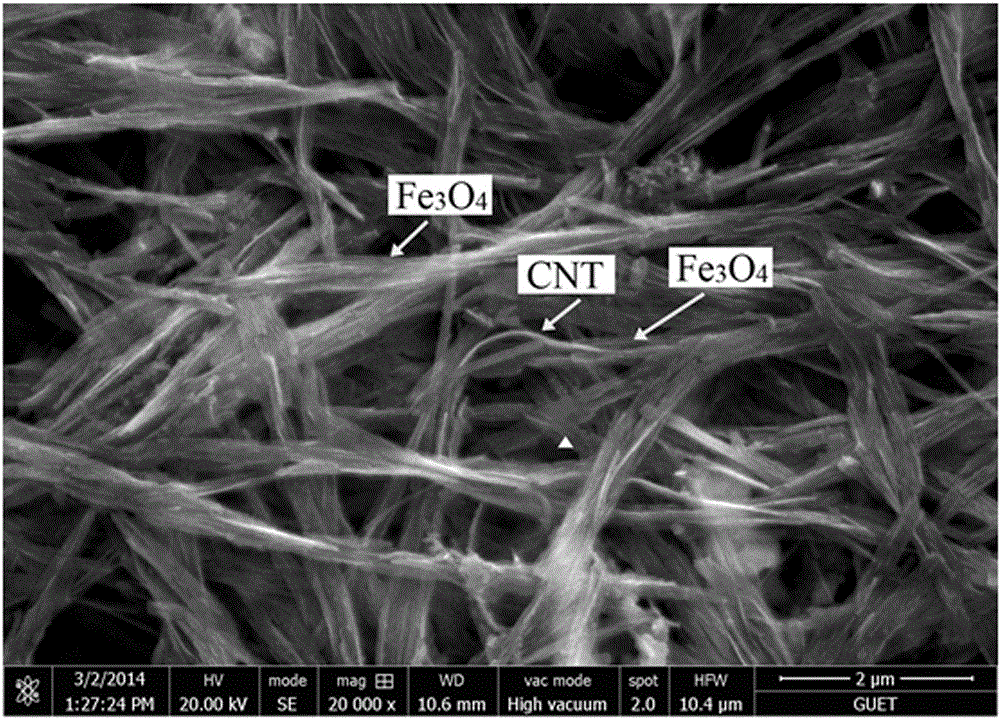

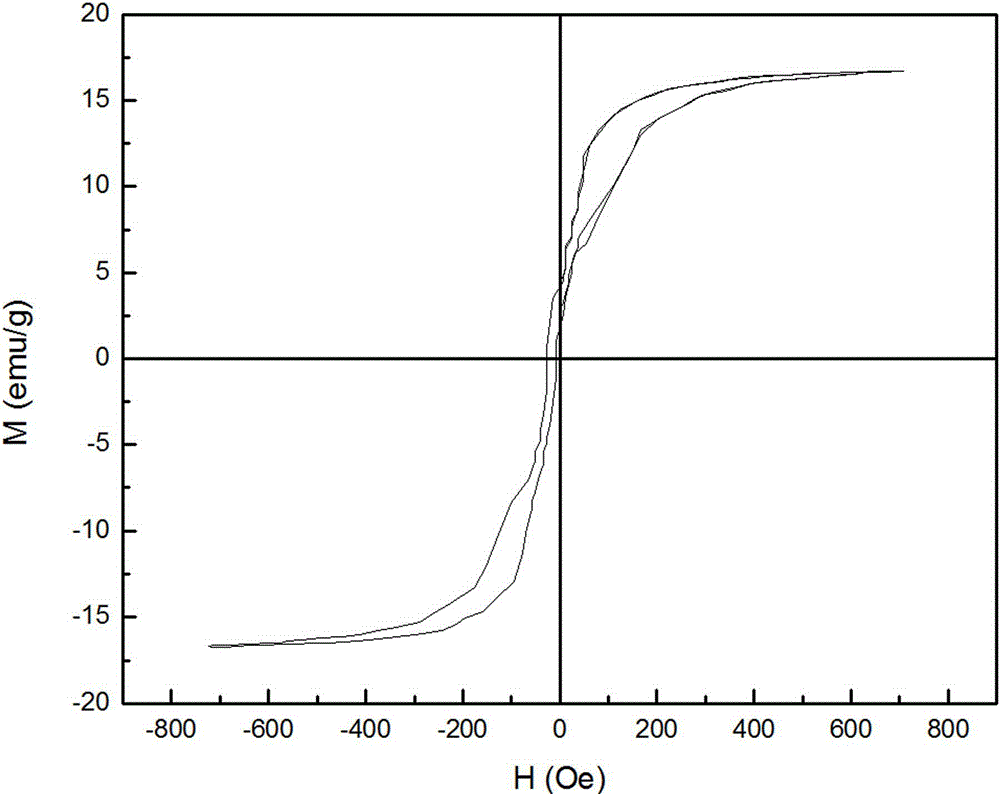

Composite material by using carbon nano-tube as core and ferriferrous oxide as shell and preparation method thereof

A technology of ferroferric oxide and carbon nanotubes, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of rare special morphology and structure, and achieve novel structure and advanced technology. Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 1 g of multi-walled carbon nanotubes, disperse them in 200 mL of deionized water, add dilute hydrochloric acid, and adjust the pH to 3.5. Add dropwise the Fenton reagent prepared by 100ml of hydrogen peroxide with a mass concentration of 30% and 100ml of a ferrous chloride solution with a concentration of 0.1mol / L under ultrasonic stirring conditions. After the dropwise addition is completed within 6 hours, add excess reduced iron powder and continue Stir ultrasonically for 0.5h, and remove excess iron powder by magnetic adsorption;

[0025] (2) Take the suspension obtained in step (1), according to Fe 2+ Concentration, add equivalent OH -1 The urea was heated up to 95°C, and reacted with mechanical stirring at 200rmp for 1h. After the end, the final product was obtained through further processes such as separation, washing, drying at 200°C, and crushing.

Embodiment 2

[0027] (1) Weigh 1 g of multi-walled carbon nanotubes, disperse them in 50 ml of deionized water, add dilute hydrochloric acid, and adjust the pH to 3.5. Under the condition of ultrasonic stirring, add Fenton's reagent () prepared by 100ml of hydrogen peroxide with a mass concentration of 30% and 20ml of ferrous chloride solution with a concentration of 0.1mol / L, and add excess reduced iron powder after 1 hour. Continue ultrasonic stirring for 0.5 h, and remove excess iron powder by magnetic adsorption.

[0028] (2) Take the suspension obtained in step (1), according to Fe 2+ Concentration, add 0.5 times the equivalent of OH -1 The hexamethylenetetramine was heated to 75°C, and reacted with mechanical stirring at 1000rmp for 4 hours. After the end, the final product was obtained through further processes such as separation, washing, drying at 80°C, and crushing.

Embodiment 3

[0030] (1) Weigh 1 g of single-walled carbon nanotubes, disperse them in 500 ml of deionized water, add dilute hydrochloric acid, and adjust the pH to 3. Under the condition of ultrasonic stirring, add the Fenton reagent prepared by 400ml of hydrogen peroxide with a mass concentration of 30% and 50ml of ferrous sulfate solution with a concentration of 0.2mol / L. After 12 hours of dropping, add excess reduced iron powder and continue ultrasonic stirring. 4h, remove excess iron powder by magnetic adsorption method.

[0031] (2) Take the suspension obtained in step (1), according to Fe 2+ Concentration, add 0.5 times the equivalent of OH -1 The hexamethylenetetramine was heated to 85°C, and reacted with mechanical stirring at 2500rmp for 12h. After the end, the final product was obtained through further processes such as separation, washing, drying at 120°C, and crushing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com