Application of phosphoric acid ester compound to flotation of calcium-containing minerals

A phosphate ester and mineral flotation technology, applied in flotation, solid separation, etc., can solve the problems of small dosage of chemicals, difficulty in flotation and separation of minerals containing calcium salts, etc., achieve low production cost, low cost, and meet the requirements of industrial The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

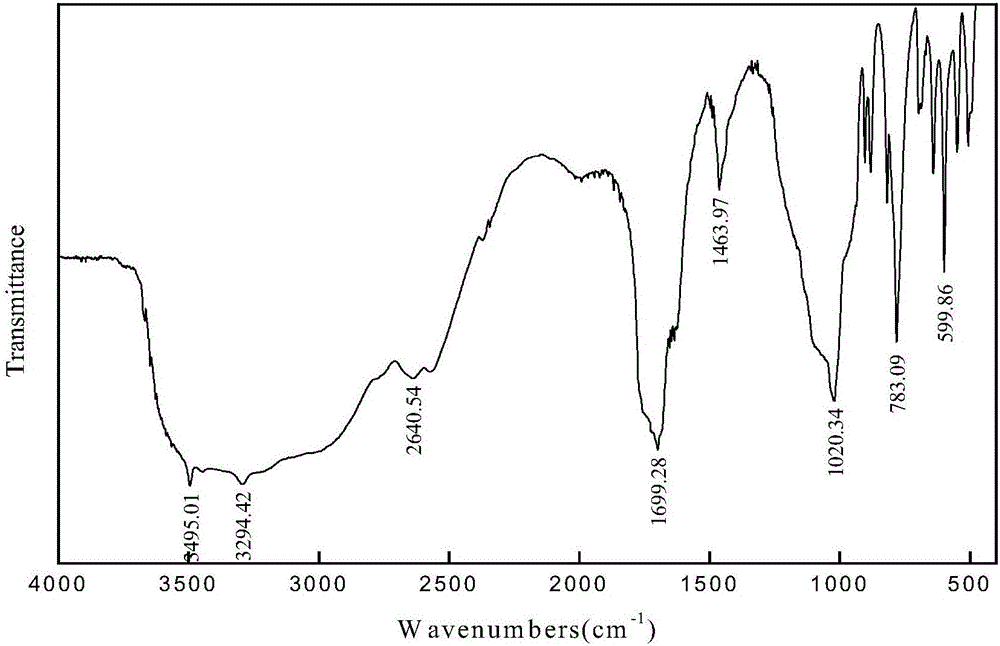

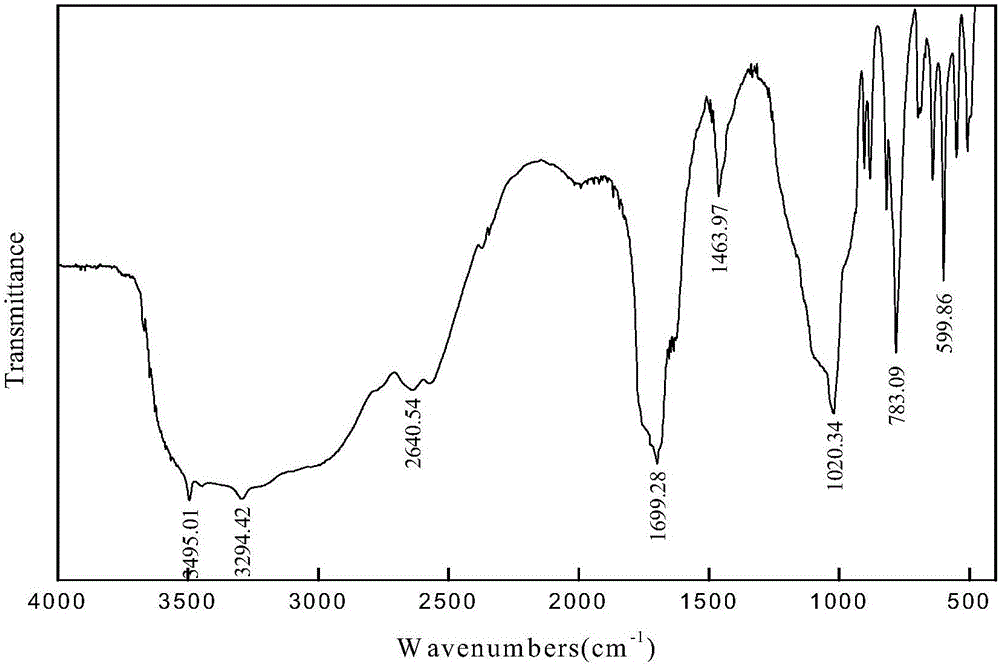

[0028] Add 10g of ethylene glycol, 40g of ethylene glycol monoethyl ether, 40g of polyoxyethylene ether glycerin (molecular weight 1500), 30g of ethylene glycol monoethyl ether into a 300mL three-necked flask equipped with a stirrer, a thermometer, a condenser and a dropping funnel. Diethyl ether, heated to 75°C under stirring and mixing, then slowly added 20g of phosphorus pentoxide, controlled the reaction temperature to reach 130-140°C after adding phosphorus pentoxide, then added 30g of ethylene glycol monoethyl ether, and heated at 140 Keep warm at ℃ for 1 hour, add water to cool the product, and obtain the desired calcite inhibitor. Its infrared spectroscopic analysis as figure 1 . It is used for the separation of calcite in fluorite flotation.

[0029] The phosphate ester compound obtained above was used for the flotation separation of fluorite and calcite. Table 1 shows the comparison results between the new agent and the traditional calcite inhibitor acidified water...

Embodiment 2

[0034] Add 10g ethylene glycol, 40g ethylene glycol monoethyl ether, 40g polyoxyethylene ether glycerin (molecular weight 1200), 30g ethylene glycol monoethyl ether to a 300mL three-neck flask equipped with a stirrer, thermometer, condenser and dropping funnel. Diethyl ether, heated to 80°C under stirring and mixing, then slowly added 20g of phosphorus pentoxide, controlled the reaction temperature to reach 130-140°C after adding phosphorus pentoxide, then added 30g of ethylene glycol monoethyl ether, and heated at 140 Keep warm at ℃ for 2 hours, add water to cool the product, and then obtain the desired calcite inhibitor. Its infrared spectroscopic analysis as figure 1 . It is used for the separation of calcite in fluorite flotation.

[0035] The phosphate ester compound obtained above was used for the flotation separation of Shizhuyuan tungsten ore and calcite. Table 2 is the comparison result of the new agent and the traditional calcite inhibitor salinized water glass. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com