Synthetic method for tetra(pentafluorophenyl)borate

A technology of pentafluorophenyl and synthetic method, applied in the field of tetraborate synthesis, can solve problems such as unfavorable industrialized production, harsh reaction conditions, harsh synthesis conditions, etc., and achieves strong technological and operational practicability, low cost, and steps simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

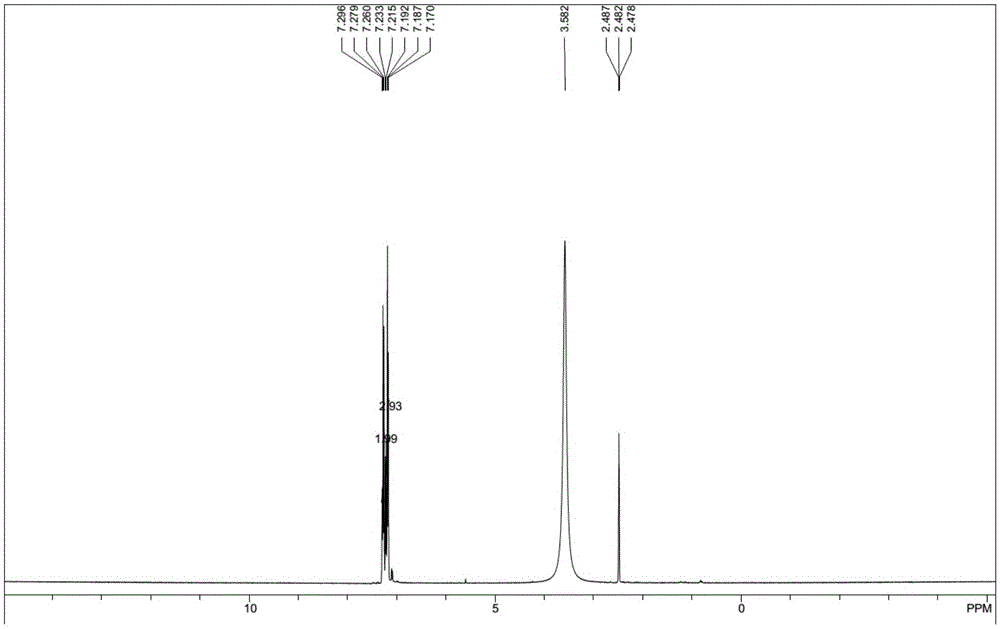

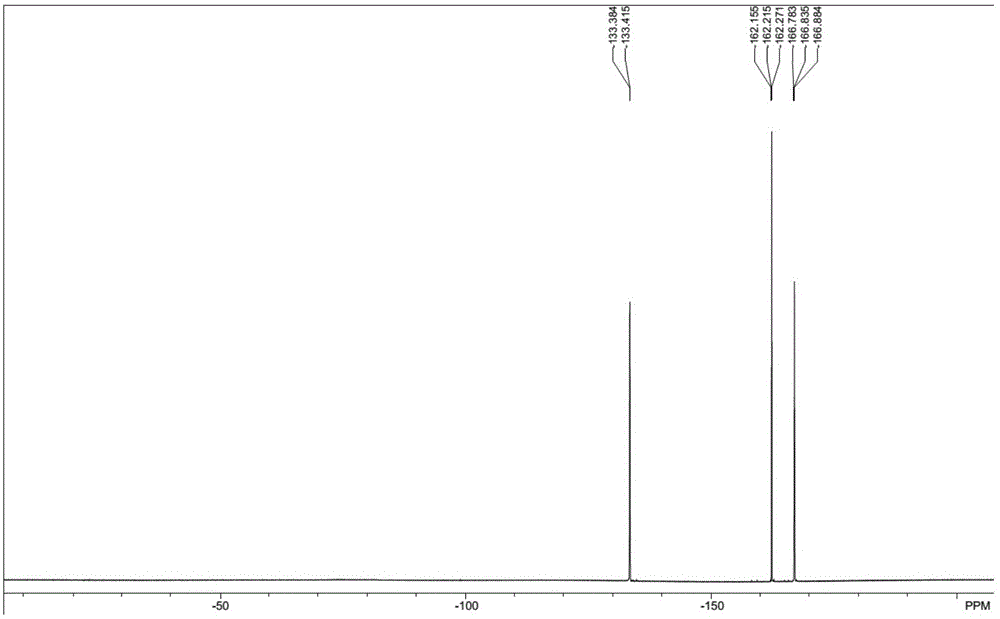

[0044] Method 1: Specifically, when M + When it is an organic carbocation or an organic ammonium ion, a synthetic method of tetrakis (pentafluorophenyl) borate is provided, comprising the following steps: using pentafluorobromobenzene as a starting material, first treating with isopropylmagnesium chloride , and then react with trimethyl borate to obtain the precursor tetrakis (pentafluorophenyl) borate magnesium salt (I), and then carry out cation exchange to obtain the product compound (II); the reaction scheme of the method is:

[0045]

[0046] In a preferred embodiment, in the synthesis method, the M + It is triphenylcarbenium ion or N,N-dimethylanilinium ion.

[0047] In a further preferred embodiment, the synthesis method comprises the following steps:

[0048] (1) Prepare the required Grignard reagent: under nitrogen protection, add 2-methyltetrahydrofuran (moisture<100ppm), magnesium chips, at least 1 drop of 1,2- Dibromoethane, stir, first drop 1 / 10-1 / 5 of 2-chl...

Embodiment 1

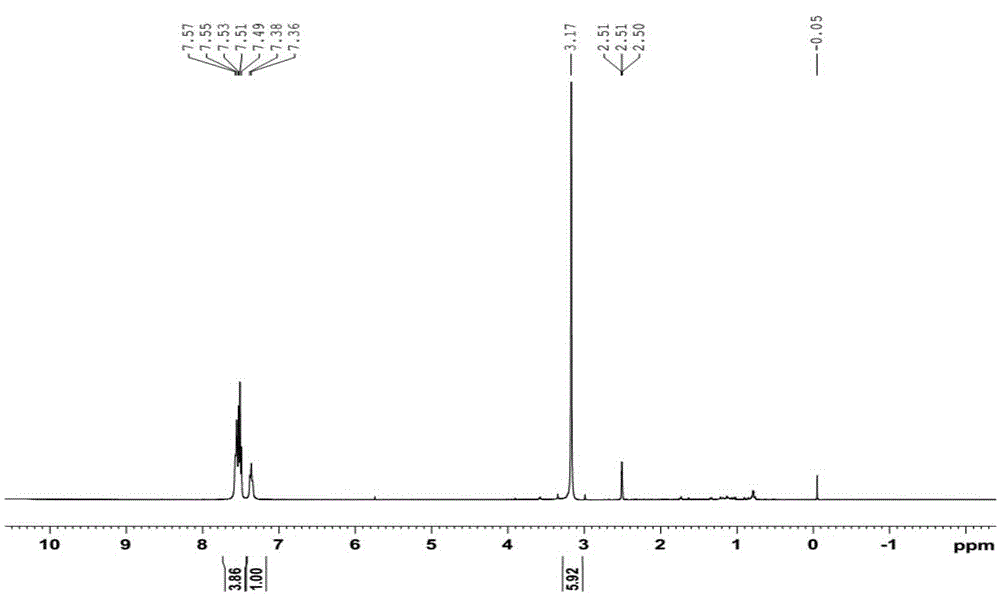

[0073] Synthesis of Triphenylcarbenium Tetrakis(pentafluorophenyl)borate

[0074] (1) Under the protection of nitrogen, add 400ml of 2-methyltetrahydrofuran (moisture <100ppm), 39.28g of magnesium chips, and 1 drop of 1,2-dibromoethane into a four-necked flask equipped with a reflux condenser (through low temperature liquid). , stir, add 125.6g 2-chloropropane and 304ml 2-methyltetrahydrofuran to the constant pressure dropping funnel, first drop in 1 / 10 of 2-chloropropane in 2-methyltetrahydrofuran solution, heat to 40°C, condense and reflux, After the reaction of the dropped 2-chloropropane is completed, add the remaining 2-chloropropane dropwise, react at 40°C until the 2-chloropropane reacts completely, and make a 2-methyltetrahydrofuran solution of isopropylmagnesium chloride, and measure its concentration by titration. The concentration is about 1.89mol / L;

[0075] (2) Under the protection of nitrogen, add 160g of pentafluorobromobenzene and 1000ml of toluene to the four...

Embodiment 2

[0079] Synthesis of N,N-Dimethylanilinium Tetrakis(pentafluorophenyl)borate

[0080] (1) Under the protection of nitrogen, add 400ml of 2-methyltetrahydrofuran (moisture <100ppm), 39.28g of magnesium chips, 3 drops of 1,2-dibromoethane , stir, add 125.6g 2-chloropropane and 304ml 2-methyltetrahydrofuran to the constant pressure dropping funnel, first drop 1 / 5 of 2-chloropropane in 2-methyltetrahydrofuran solution, heat to 40°C, condense and reflux, After the reaction of the 2-chloropropane that has been dropped, add the remaining 2-chloropropane dropwise, react at 40°C until the 2-chloropropane reacts completely, and make a 2-methyltetrahydrofuran solution of isopropylmagnesium chloride, and measure its concentration by titration About 1.89mol / L;

[0081] (2) Under the protection of nitrogen, add 160g of pentafluorobromobenzene and 1000ml of toluene into the four-necked flask, stir and cool down to 0°C, add 321ml of isopropylmagnesium chloride in 2-methyltetrahydrofuran solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com