A method for controlling abrasive particle size in nano-diamond polishing liquid

A technology of nano-diamond and abrasive particle size, applied in polishing compositions containing abrasives, etc., can solve the problems of low classification efficiency and complex classification process, and achieve the effect of stable product performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) First weigh 1 g of commercially available nano-diamond prepared by detonation method and 0.13 g of sodium hexametaphosphate, and ultrasonically disperse in mechanical stirring or deionized water to prepare a dispersion with a mass fraction of 1%, and then place it in a high-energy ball mill , ball milled for 1 hour, took out the dispersion, filtered through 0.5um filter paper to remove impurities, adjusted the pH value to 8 with 0.2g of ammonia water, added 0.6g of sodium dodecylbenzenesulfonate, 10g of polyethylene glycol 200, and ultrasonicated for 60min. The power is 3000W, and the nano-diamond polishing liquid with an average particle size of 30nm is obtained, which is used as the mother liquid for controlling the abrasive grain size in the nano-diamond polishing liquid.

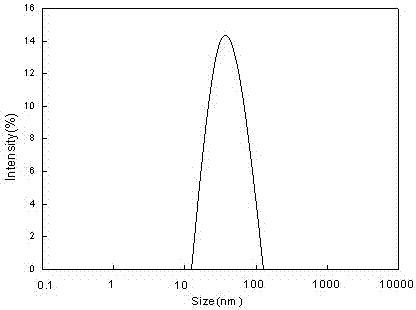

[0031] (2) Add 0.06g of Nacl and 10g of ethylene glycol to the nano-diamond polishing solution obtained in step (1) with an average particle size of 30nm, stir, ultrasonic time for 20min, and u...

Embodiment 2

[0033] (1) First weigh 0.2g of commercially available nano-diamond prepared by detonation method and 0.15g of ammonium sulfate, and ultrasonically disperse in mechanical stirring or deionized water to prepare a dispersion with a mass fraction of 0.2%, and then place it in a high-energy ball mill, Ball mill for 1 hour, take out the dispersion, filter through 0.5um filter paper to remove impurities, adjust the pH value to 5 with 0.15g citric acid, add 1.2g sodium dodecylbenzenesulfonate, 5g polyethylene glycol 400, ultrasonic 40min, ultrasonic The power is 2500W, and the nano-diamond polishing liquid with an average particle diameter of 30nm is obtained. It is used as the mother liquid for abrasive grain size control in nano-diamond polishing liquid.

[0034] (2) Add 0.04 g of dispersant KCl, 18 g of glycerin, and 8 g of ethylene glycol to the mother liquid of nano-diamond polishing solution obtained in step (1) with an average particle size of 30 nm, stir, ultrasonic time 20 mi...

Embodiment 3

[0036] (1) Similar to Example 2, a nano-diamond polishing solution with an average particle size of 30 nm was prepared as a mother solution for controlling the abrasive particle size in the nano-diamond polishing solution.

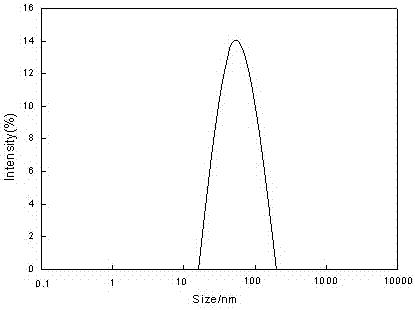

[0037] (2) Add 0.02 g of dispersant KCl, 4 g of glycerin, and 1 g of ethylene glycol to the mother liquid of nano-diamond polishing liquid obtained in step (1) with an average particle size of 30 nm, stir, ultrasonic time for 10 min, and ultrasonic power of 600 W to obtain an average Nano-diamond polishing liquid with a particle size of 60nm. The particle size distribution of 60nm particle size nano-diamond polishing liquid is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com