Copper-zinc alloy electroplate liquid and electroplating method thereof

An alloy electroplating solution, copper-zinc technology, applied in the field of electroplating solution, can solve the problems of poor wear resistance and corrosion resistance of the coating, poor stability, and difficulty in obtaining a stable coating, and achieve good corrosion resistance and wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

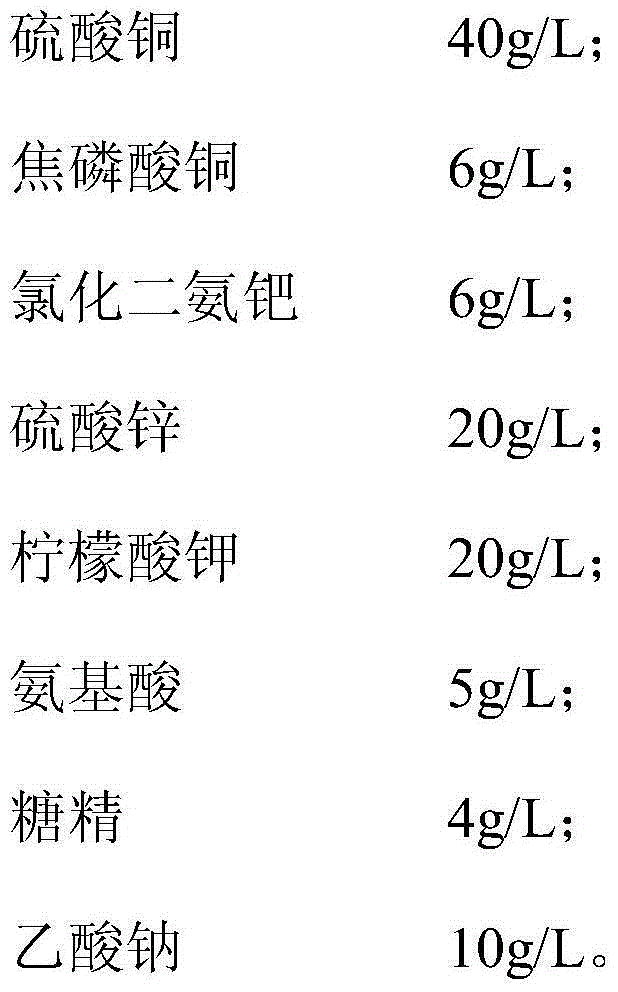

[0021] Embodiment 1: the copper-zinc alloy electroplating solution of the present embodiment comprises following components:

[0022]

[0023] Use above-mentioned copper-zinc alloy electroplating solution electroplating method as follows:

[0024] Configure copper-zinc alloy electroplating solution: dissolve potassium citrate in deionized water to make a solution, add copper sulfate, copper pyrophosphate, diammonium palladium chloride and amino acid to the solution, stir and dissolve to form a mixed solution, and add to the mixed solution Add saccharin and sodium acetate to dissolve to prepare copper-zinc alloy electroplating solution; wherein, the concentration of copper sulfate in the copper-zinc alloy electroplating solution is 40g / L, the concentration of copper pyrophosphate is 6g / L, diammonium chloride The concentration of palladium is 6g / L, the concentration of zinc sulfate is 20g / L, the concentration of potassium citrate is 20g / L, the concentration of amino acid is 5...

Embodiment 2

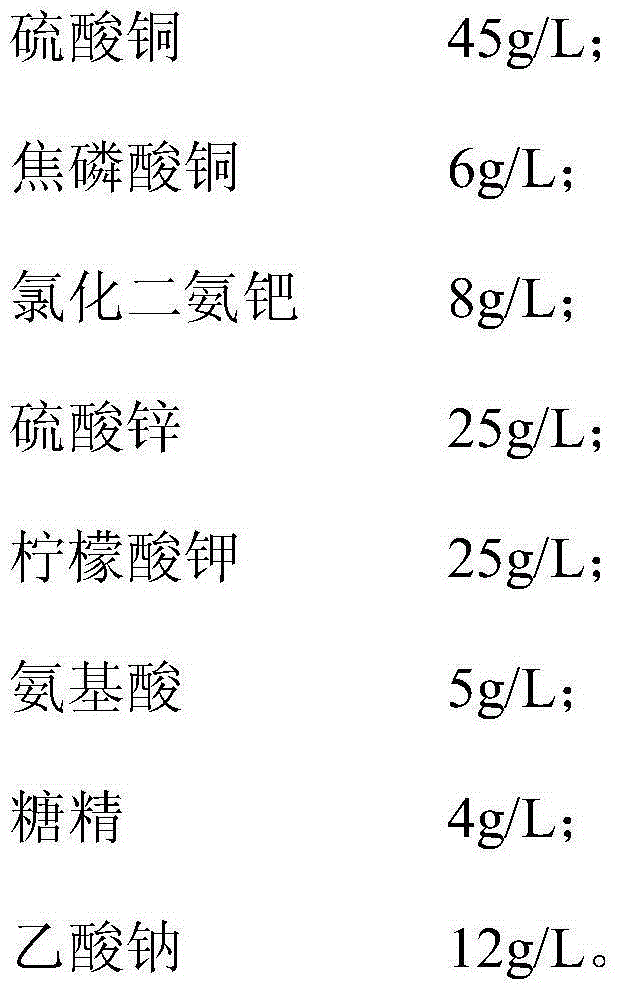

[0026] Embodiment 2: the copper-zinc alloy electroplating solution of the present embodiment comprises following components:

[0027]

[0028] Use above-mentioned copper-zinc alloy electroplating solution electroplating method as follows:

[0029] Configure copper-zinc alloy electroplating solution: dissolve potassium citrate in deionized water to make a solution, add copper sulfate, copper pyrophosphate, diammonium palladium chloride and amino acid to the solution, stir and dissolve to form a mixed solution, and add to the mixed solution Add saccharin and sodium acetate to dissolve to prepare copper-zinc alloy electroplating solution; wherein, the concentration of copper sulfate in the copper-zinc alloy electroplating solution is 45g / L, the concentration of copper pyrophosphate is 6g / L, diammonium chloride The concentration of palladium is 8g / L, the concentration of zinc sulfate is 25g / L, the concentration of potassium citrate is 25g / L, the concentration of amino acid is 5...

Embodiment 3

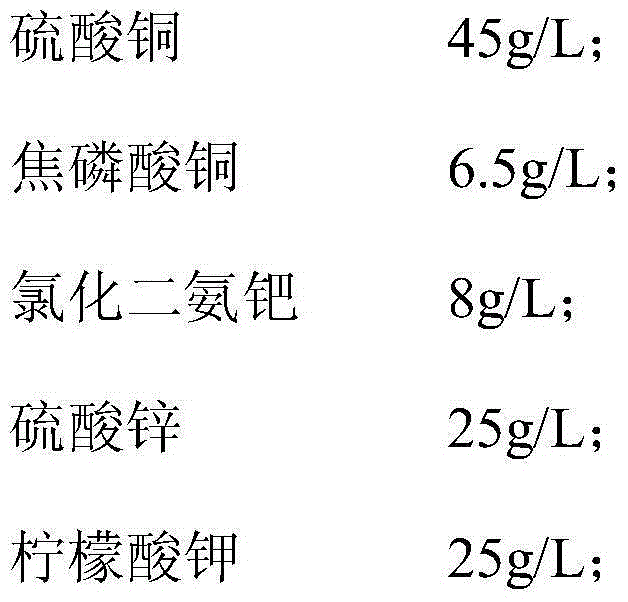

[0031] Embodiment 3: the copper-zinc alloy electroplating solution of the present embodiment comprises following components:

[0032]

[0033]

[0034] Use above-mentioned copper-zinc alloy electroplating solution electroplating method as follows:

[0035] Configure copper-zinc alloy electroplating solution: dissolve potassium citrate in deionized water to make a solution, add copper sulfate, copper pyrophosphate, diammonium palladium chloride and amino acid to the solution, stir and dissolve to form a mixed solution, and add to the mixed solution Add saccharin and sodium acetate to dissolve, and prepare copper-zinc alloy electroplating solution; Wherein, the concentration of copper sulfate in the copper-zinc alloy electroplating solution is 45g / L, the concentration of copper pyrophosphate is 6.5g / L, dichloride The concentration of ammonia palladium is 8g / L, the concentration of zinc sulfate is 25g / L, the concentration of potassium citrate is 25g / L, the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com