A kind of far-infrared multifunctional drying method

A drying method, far-infrared technology, applied in the direction of drying solid materials, drying gas arrangement, local agitation dryers, etc., can solve the problems of long working hours, scorched waste, uneven heating, etc., to reduce aflatoxin lesions , increase speed and efficiency, and shorten drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

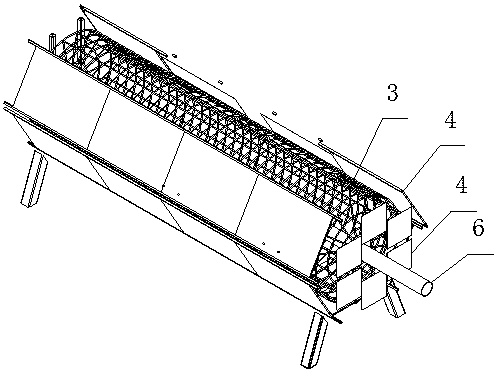

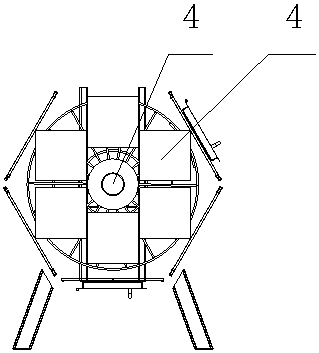

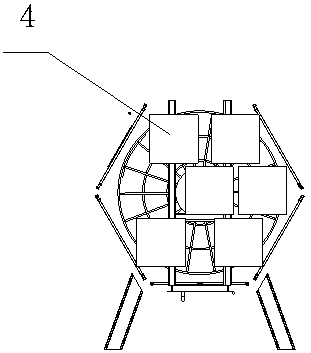

[0044] Please see attached figure 1 to attach Figure 7 , figure 1 It is a three-dimensional structure layout diagram of the far-infrared multifunctional drying system of the present invention, Figure 7 It is the general assembly drawing of the three-dimensional structure of the far-infrared multifunctional drying system of the present invention, please refer to figure 1 , Figure 7 , a far-infrared multifunctional drying system, a far-infrared multifunctional drying system, which includes: a far-infrared light-wave drying box main body 1, and a plurality of groups of far-infrared plane radiation light-wave electrothermal materials are arranged in the far-infrared light-wave drying box main body 1 4. An intelligent sensor control system is installed on the main body 1 of the far-infrared light-wave drying oven to monitor the main body 1 of the far-infrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com