Medium composition for filter material used for hydrophilic and oleophobic separator

The technology of a hydrophilic and oleophobic separator is applied in the field of filter materials of hydrophilic and oleophobic separators, which can solve the problems of restricting the popularization and application of fiber ball filter materials, easy adhesion of fiber balls into agglomerates, and difficulty in washing and regeneration. The effect of long filtration cycle, strong regeneration ability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A filter media composition for a hydrophilic-oleophobic separator, made from the following raw materials in parts by weight:

[0029] 28 walnut shells

[0030] 2 parts polytetrafluoroethylene

[0031] 70 parts of ceramic particles.

[0032] The above-mentioned ceramic particles are made of the following raw materials in parts by weight:

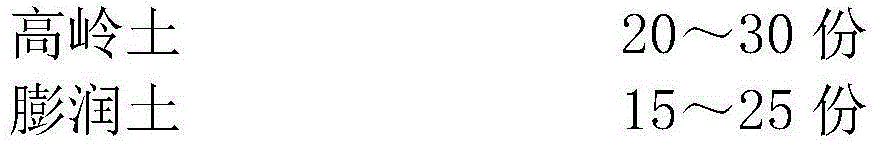

[0033]

[0034] The preparation method of above-mentioned ceramic particle, comprises the following steps:

[0035] 1) Take kaolin, bentonite, sepiolite and limestone according to the formula, and ball mill for 18 hours;

[0036] 2) Add the formula to measure water and leave it for 6 hours;

[0037] 3) granulate into a ball with a diameter of 1.6mm, and dry to a moisture content of 6%;

[0038] 4) Burning at a temperature of 1140° C. for 50 minutes at a heating rate of 2° C. / min, and cooling down to room temperature.

Embodiment 2

[0040] A filter media composition for a hydrophilic-oleophobic separator, made from the following raw materials in parts by weight:

[0041] 30 walnut shells

[0042] 3 parts polytetrafluoroethylene

[0043] 67 parts of ceramic particles.

[0044] The above-mentioned ceramic particles are made of the following raw materials in parts by weight:

[0045]

[0046] The preparation method of above-mentioned ceramic particle, comprises the following steps:

[0047] 1) Take kaolin, bentonite, sepiolite and limestone according to the formula, and ball mill for 19 hours;

[0048] 2) Add formula and measure water, and leave for 5 hours;

[0049] 3) granulate into a ball with a diameter of 1.8mm, and dry to a moisture content of 5%;

[0050] 4) Burning at 1120°C for 60 minutes at a heating rate of 2°C / min, and cooling down to room temperature.

Embodiment 3

[0052] A filter media composition for a hydrophilic-oleophobic separator, made from the following raw materials in parts by weight:

[0053] 33 walnut shells

[0054] 4 parts polytetrafluoroethylene

[0055] 63 parts of ceramic particles.

[0056] The above-mentioned ceramic particles are made of the following raw materials in parts by weight:

[0057]

[0058] The preparation method of above-mentioned ceramic particle, comprises the following steps:

[0059] 1) Take kaolin, bentonite, sepiolite and limestone according to the formula, and ball mill for 21 hours;

[0060] 2) Add formula and measure water, and leave for 4 hours;

[0061] 3) granulate into a ball with a diameter of 2.1mm, and dry to a moisture content of 4%;

[0062] 4) Burning at 1090°C for 75 minutes at a heating rate of 3°C / min, then cooling down to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com