Oil-resistant, thermal-insulating and anti-corrosion adhesive tape

A thermal insulation and adhesive tape technology, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of poor oil resistance, fading and pulverization, and fast aging of anti-corrosion tapes, and achieve long service life, strong oil repellency, The effect of low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

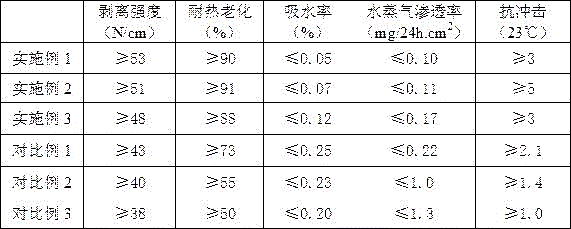

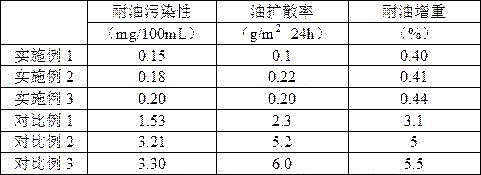

Examples

Embodiment 1

[0018] An oil-resistant, heat-insulating and anti-corrosion adhesive tape consists of two parts: a base layer and an adhesive layer:

[0019] The adhesive layer (0.8 mm in thickness) is composed of the following raw materials in parts by weight: 50 parts of epoxy resin, 0.9 parts of hydroxyfluorosilicone oil, 3 parts of zinc phosphate, 2 parts of silica balls, 1 part of rhodamine B, sulfonated amber Dioctyl acid sodium salt 1.2 parts, silicon boride 6 parts, fatty acid amide 3 parts, polyvinyl alcohol 2 parts.

[0020] The base layer is a polyethylene film; the polyethylene film is pre-smeared with a layer of treatment solution (the treatment solution is composed of 1 part of mussel mucin, 6 parts of ethanol, 10 parts of polyethylene acetate, 0.3 parts of polyethylene glycol parts); the application amount of treatment liquid is 5-10g / m 3 ;

[0021] The silica spheres are prepared by the following method: add glycerin aqueous solution with a volume fraction of 10% to carbon ...

Embodiment 2

[0025] An oil-resistant, heat-insulating and anti-corrosion adhesive tape consists of two parts: a base layer and an adhesive layer:

[0026] The adhesive layer (with a thickness of 0.7mm) is composed of the following raw materials in parts by weight: 52 parts of epoxy resin, 1 part of hydroxyfluorosilicone oil, 4 parts of zinc phosphate, 3 parts of silica balls (the preparation method is the same as in Example 1), Rhodamine B 0.5 part, dioctyl sulfosuccinate sodium salt 0.8 part, silicon boride 7 parts, fatty acid amide 4 parts, polyvinyl alcohol 1 part.

[0027] The base layer is a polyethylene film; the polyethylene film is pre-smeared with a layer of treatment solution (the treatment solution is composed of 1 part of mussel mucin, 6 parts of ethanol, 10 parts of polyethylene acetate, 0.3 parts of polyethylene glycol parts); the application amount of treatment liquid is 5-10g / m 3 .

Embodiment 3

[0029] An oil-resistant, heat-insulating and anti-corrosion adhesive tape consists of two parts: a base layer and an adhesive layer:

[0030] The adhesive layer (with a thickness of 0.6mm) is composed of the following raw materials in parts by weight: 55 parts of epoxy resin, 0.8 parts of hydroxyfluorosilicone oil, 5 parts of zinc phosphate, 3 parts of silica balls (the preparation method is the same as in Example 1), 2 parts of rhodamine B, 1.5 parts of dioctyl sulfosuccinate sodium salt, 5 parts of silicon boride, 5 parts of fatty acid amide, and 2 parts of polyvinyl alcohol.

[0031] The base layer is a polyethylene film; the polyethylene film is pre-smeared with a layer of treatment solution (the treatment solution is composed of 1 part of mussel mucin, 6 parts of ethanol, 10 parts of polyethylene acetate, 0.3 parts of polyethylene glycol parts); the application amount of treatment liquid is 5-10g / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com